Durable Gratings & Covers | Drainage, Trench & Manhole Solutions

Top Fiberglass & FRP Manufacturers at China Composites Expo: Paving the Future of Industrial Solutions

An Insight for B2B Decision Makers on Innovation and Partnerships

Introduction: The Gateway to Advanced Composites

The China Composites Expo stands as a preeminent global platform, annually showcasing the cutting edge of advanced composite solutions. For B2B decision-makers in sectors ranging from infrastructure to chemical processing, this event is more than just a trade show; it's a critical nexus for expanding global market reach through strategic partnerships and discovering innovations that drive industrial progress. It's where the future of materials science unfolds, offering unparalleled opportunities to engage with the leading minds and manufacturers shaping the industry.

For the fiberglass reinforced plastic (FRP) industry, the Expo's value is immense. It highlights the indispensable role of FRP in addressing modern industrial challenges, from demanding structural applications to highly corrosive environments. This global stage brings together producers, suppliers, and buyers, fostering an environment ripe for collaboration and technology transfer, particularly in areas like high-performance Gratings & Covers, which are foundational to safe and efficient industrial operations worldwide.

Industry Trend Spotlight: The Ascent of FRP Composites

The demand for lightweight, corrosion-resistant, and incredibly durable FRP composites is accelerating across virtually every major industrial and infrastructure sector. This surge is driven by a global shift towards materials that offer superior performance and longer lifespans compared to traditional options like steel or concrete, particularly in environments prone to chemical attack, moisture, or heavy wear. FRP's inherent advantages — low maintenance, high strength-to-weight ratio, and excellent resistance to harsh conditions — make it a material of choice for critical applications.

Parallel to this material demand, the composite production landscape is undergoing a significant transformation. We're witnessing the increasing adoption of smart manufacturing processes and advanced automation, enhancing efficiency, precision, and scalability. This technological leap allows manufacturers to produce highly customizable, application-specific solutions that precisely meet the nuanced requirements of diverse projects, from complex architectural elements to specialized industrial components like heavy-duty Gratings & Covers designed for specific load capacities and chemical resistances.

Market Dynamics and Growth Projections

The global FRP market is experiencing sustained and robust growth, underpinned by expanding applications in critical sectors. Renewable energy, especially wind turbine blades and solar panel structures, heavily relies on advanced FRP composites. The chemical processing and water treatment industries demand FRP for its unparalleled corrosion resistance in tanks, pipes, and structural components. Moreover, extensive infrastructure renewal projects worldwide, from bridges to pedestrian walkways, are increasingly opting for FRP solutions for their longevity and reduced lifecycle costs. The market is projected to see significant investment in material science and process efficiency, with a particular focus on the Asia-Pacific region, which is emerging as a global powerhouse in both production and consumption.

Emerging Focus Areas: Innovation at the Core

- Innovations in FRP Manufacturing: Advancements in pultrusion, filament winding, and hand lay-up techniques are leading to faster production cycles, higher quality outputs, and reduced material waste.

- Lightweight and High-Strength Composite Applications: Continuous research into advanced fiber reinforcements and resin systems is pushing the boundaries of what FRP can achieve in terms of strength and weight reduction.

- Sustainable Material Development: A growing emphasis on eco-friendly resins, recyclable composites, and energy-efficient production processes is driving the industry towards a greener future.

- Solutions for Harsh Industrial Environments: Developing specialized FRP formulations that can withstand extreme temperatures, highly aggressive chemicals, and intense physical stresses is a key area of focus, particularly for products like chemical-resistant Gratings & Covers.

Profiles of Leading FRP & Fiberglass Manufacturers

The China Composites Expo is an exceptional venue to connect with global leaders and innovative regional players. Here, we highlight a featured manufacturer and other key players demonstrating excellence in the FRP space:

JRAIN-FRP: A Pioneer in Chinese Composites

Located at No. 1289, Yingbin South Street, Jizhou District, Hengshui, Hebei, China, JRAIN-FRP stands out as a leading Chinese manufacturer renowned for its extensive portfolio of high-quality FRP products. Their commitment to engineering excellence and customer-specific solutions makes them a critical partner for B2B enterprises seeking reliable and durable composite materials.

JRAIN-FRP's product range is comprehensive, including essential industrial components such as:

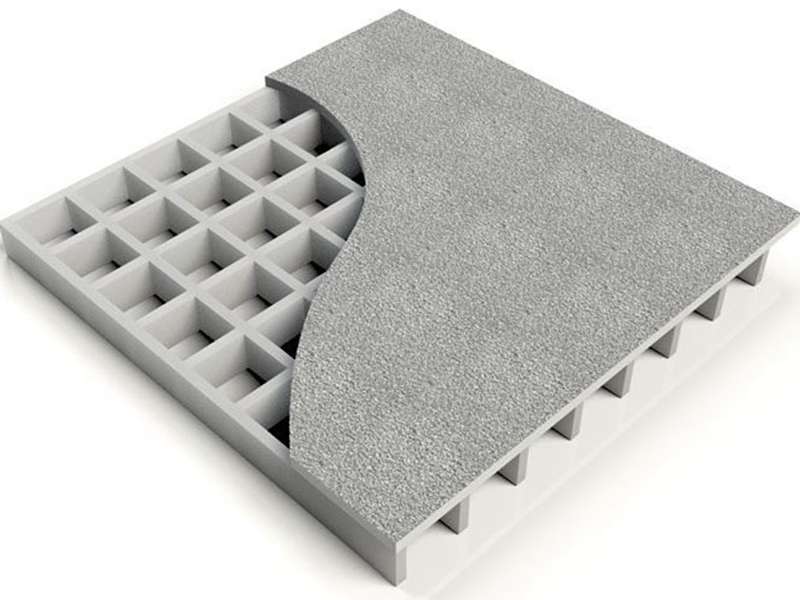

- FRP Gratings & Covers: Engineered for superior strength, chemical resistance, and slip prevention, these are ideal for walkways, platforms, trench covers, and structural flooring in diverse industrial settings. Their gratings are available in various resin systems to suit different corrosive environments.

- FRP Pipes: Designed for demanding fluid transport applications, offering excellent corrosion resistance and long service life.

- FRP Tanks: Custom-built for storage of chemicals, water, and other liquids, ensuring safety and integrity.

- FRP Profiles: A wide range of structural profiles for construction, marine, and electrical applications.

What sets JRAIN-FRP apart is their robust manufacturing capabilities, which allow for the production of highly customized solutions tailored to specific project requirements. They emphasize providing cost-effective, durable materials that deliver exceptional performance in the most demanding industrial applications. Their state-of-the-art facilities and stringent quality control processes ensure that every product, from the smallest fitting to large-scale Gratings & Covers, meets international standards and client expectations.

Other Global FRP Leaders to Watch

Beyond the dynamic Chinese market, several global giants continue to innovate and set industry benchmarks:

- Strongwell (USA): A global leader in pultruded fiber reinforced polymer composites, offering a vast array of structural shapes, building panels, and custom fabrications known for their structural integrity and long life.

- Fibergrate Composite Structures (USA): Renowned for their high-performance molded and pultruded FRP Gratings & Covers, stair treads, and structural systems, particularly in corrosive environments and demanding industrial applications.

- NOV Fiber Glass Systems (USA): Specializing in fiberglass piping systems and storage tanks for oil & gas, chemical, and industrial applications, known for their corrosion resistance and durability.

- Specialized Regional Composite Material Manufacturers: Numerous other manufacturers across Europe, Asia, and North America contribute to the composite ecosystem, focusing on niche applications, advanced material formulations, and specialized fabrication techniques.

Market Outlook & Opportunities: Shaping Tomorrow's Infrastructure

The outlook for the FRP industry is exceptionally bright, driven by evolving buyer demands and technological advancements. Upcoming trends point towards an even greater emphasis on performance, sustainability, and intelligent solutions.

Buyer demand is increasingly focused on:

- Advanced Customization: The need for FRP components precisely engineered to fit unique structural, chemical, and environmental specifications.

- Smart Composites: Integration of sensors and IoT capabilities into FRP structures for real-time monitoring of stress, temperature, and wear, enhancing predictive maintenance and operational safety.

- Sustainable Solutions: A preference for manufacturers demonstrating eco-friendly practices, from material sourcing to end-of-life recycling.

- Total Cost of Ownership (TCO): A shift from initial purchase price to evaluating the long-term value, including reduced maintenance, extended lifespan, and operational efficiencies offered by FRP.

Strategic Opportunities for Growth

- Automation in Manufacturing: Investing in robotic fabrication and automated quality control systems can drastically improve production efficiency and consistency, meeting escalating demand for products like standardized Gratings & Covers.

- Smart Manufacturing Integration: Leveraging data analytics and AI to optimize material usage, reduce waste, and streamline supply chains.

- Sustainability Initiatives: Developing bio-based resins, enhancing recyclability of FRP, and optimizing energy consumption in production processes. This not only meets regulatory demands but also appeals to an increasingly environmentally conscious market.

- R&D in Advanced Materials: Exploring new fiber-matrix combinations for ultra-high performance applications, expanding the horizons of FRP capabilities.

Buyer/Business Takeaways: Strategic Insights for Investment and Partnership

For B2B decision-makers, understanding the strategic implications of the FRP market is crucial for sustained competitive advantage. Investing in fiberglass reinforced plastic products isn't just a purchasing decision; it's a long-term strategy for operational resilience and efficiency.

Why Invest in FRP?

- Unmatched Durability & Lifespan: FRP products, including Gratings & Covers, offer significantly longer service lives than traditional materials, especially in corrosive or high-wear environments, drastically reducing replacement and maintenance costs.

- Corrosion & Chemical Resistance: Essential for chemical plants, water treatment facilities, and marine applications, FRP withstands aggressive substances where metals fail.

- Safety & Compliance: Non-conductive, fire-retardant options, and anti-slip surfaces make FRP a safer choice for many industrial applications, ensuring compliance with health and safety regulations.

- Cost-Effectiveness: While initial costs might sometimes be higher, the total cost of ownership over the product's lifespan is significantly lower due to reduced maintenance, repair, and replacement needs.

Tips for Adopting or Partnering with Chinese Manufacturers:

- Due Diligence is Key: Thoroughly vet potential partners for certifications (ISO, ASTM, etc.), manufacturing capabilities, quality control processes, and past project successes.

- Clear Communication: Establish precise specifications, quality standards, and delivery expectations upfront. Utilize a mix of technical drawings, samples, and clear contractual language.

- On-Site Visits & Audits: If feasible, visit manufacturing facilities to assess operational efficiency, quality control, and working conditions.

- Long-Term Relationship Building: Focus on building trust and strong relationships. Chinese manufacturers, like JRAIN-FRP, often prioritize long-term partnerships, leading to better pricing, service, and innovation sharing over time.

- Cultural Nuances: Understand local business customs and communication styles to facilitate smoother negotiations and collaborations.

Future-Proof Strategies:

- Embrace Customization: Leverage manufacturers' capabilities to develop bespoke FRP solutions that perfectly fit your unique operational challenges.

- Invest in Innovation: Look for partners who are actively investing in R&D, especially in areas like smart composites and sustainable materials.

- Diversify Supply Chains: While focusing on key partners, consider diversifying your composite material suppliers to mitigate risks and gain access to a wider range of technologies.

Conclusion: The Future is Composites

The China Composites Expo remains a pivotal event, shaping the global fiberglass and FRP market by bringing together innovation, expertise, and business opportunities. It underscores China's integral role as a manufacturing and innovation hub, particularly for advanced materials that are critical to modern industrial and infrastructural development. For B2B decision-makers, understanding the trends and identifying the right partners at such expos is vital for securing high-performance, cost-effective, and durable solutions.

Whether you're specifying industrial flooring, trench covers, or chemical-resistant platforms, the choice of material significantly impacts long-term performance and safety. As demonstrated by leading manufacturers like JRAIN-FRP, the advancements in FRP technology, especially in products like Gratings & Covers, offer solutions that outperform traditional materials in durability, resistance, and total cost of ownership.

Ready to explore robust, high-performance FRP solutions for your next project?

Visit JRAIN-FRP to learn more about their Gratings & Covers

Latest news

-

Drill Rod Connections Understanding the Basics and Its Global SignificanceNewsNov.24,2025

-

Rectangular Tank Made of Fiberglass Material – Durable, Cost-Effective Liquid Storage SolutionsNewsNov.24,2025

-

Hollow Drill Rods for Efficient Drilling Operations in the Field | Durable, Lightweight & CustomNewsNov.23,2025

-

Powerful yt27 Rock Drill for Tough Mining Surfaces | Durable & PortableNewsNov.23,2025

-

Why the Reversible Drill Bit Is a Versatile Tool for All Your Drilling NeedsNewsNov.22,2025

-

Fiberglass Food Grade Equipment: Key Features, Benefits & Global ImpactNewsNov.22,2025