-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

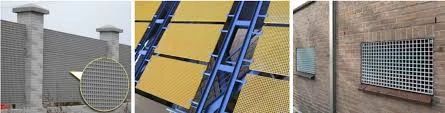

Innovative Fiberglass Filtration Solutions for Effective Water Clarification Systems

Understanding the Fiberglass Clarifier System An Essential Component for Water Treatment

In the realm of water treatment, the significance of a reliable clarifier system cannot be overstated. Among various options available, the fiberglass clarifier system has gained considerable attention due to its durability, efficiency, and adaptability. This article delves into the components, advantages, and applications of fiberglass clarifier systems, highlighting why they are becoming a preferred choice in various industries.

What is a Fiberglass Clarifier System?

A clarifier is a device designed to separate solids from liquids through sedimentation. The fiberglass clarifier system utilizes fiberglass-reinforced plastic (FRP) for its construction, making it lightweight, corrosion-resistant, and able to withstand challenging environmental conditions. This system typically consists of a settling tank, an inlet for influent, an outlet for treated water, and mechanisms for sludge removal.

Key Components of a Fiberglass Clarifier System

1. Settling Tank The heart of the clarifier system, the settling tank is where the separation of solids from liquids occurs. The design often includes a sloped bottom to facilitate the collection of settled sludge.

2. Inlet and Outlet The influent enters the clarifier through an inlet zone that often has features to distribute the flow evenly across the tank. The treated effluent is then released through an outlet, ensuring that only the clarified liquid is discharged.

3. Sludge Zone At the bottom of the clarifier, a sludge zone is where accumulated solids gradually consolidate. Periodic removal of this sludge is essential to maintain optimal operation.

4. Fiberglass Construction The use of fiberglass in construction not only enhances the longevity of the clarifier but also offers resistance to a variety of chemicals. This characteristic makes it suitable for industries like wastewater treatment, chemical processing, and food and beverage production.

Advantages of Fiberglass Clarifier Systems

1. Corrosion Resistance Unlike traditional metal clarifiers that can succumb to rust and corrosion, fiberglass remains unaffected by harsh environments, leading to lower maintenance costs and a longer service life.

2. Lightweight Design The lightweight nature of fiberglass makes installation easier and reduces transportation costs. This is particularly beneficial for projects in remote or challenging locations.

fiberglass clarifier system

3. Cost-Effective Though the initial investment may be slightly higher than alternative materials, the long-term savings from reduced maintenance and operational downtime make fiberglass clarifiers a cost-effective choice.

4. Customizable Fiberglass clarifiers can be manufactured in various sizes and configurations to meet specific project requirements. Their adaptability makes them suitable for a broad range of applications, from small-scale residential systems to large industrial processes.

5. Effective Performance With well-designed flow patterns and sedimentation processes, fiberglass clarifiers can achieve high levels of clarity. This ensures compliance with environmental regulations for discharged water.

Applications of Fiberglass Clarifier Systems

Fiberglass clarifier systems are utilized in a wide range of industries. Some notable applications include

- Municipal Wastewater Treatment As cities expand, efficient wastewater treatment becomes crucial. Fiberglass clarifiers play a vital role in ensuring that municipal effluents meet safety standards before discharge.

- Industrial Processing Industries such as food and beverage, pharmaceuticals, and chemical manufacturing frequently employ fiberglass clarifiers for effective separation of solids from process water.

- Stormwater Management In areas where stormwater runoff presents a challenge, fiberglass clarifiers help manage and treat water before it enters natural waterways or sewage systems.

- Mining and Mineral Processing The mining sector employs clarifiers to treat process water and ensure the removal of particulates, safeguarding both land and water resources.

Conclusion

The fiberglass clarifier system represents a critical innovation in the field of water treatment. With its unmatched durability, cost-effectiveness, and customizability, it addresses the growing demand for efficient and reliable water treatment solutions. As industries continue to prioritize sustainable practices and regulatory compliance, the fiberglass clarifier system will undoubtedly play a pivotal role in safeguarding water quality and protecting environmental resources for future generations. Whether for municipal applications or industrial processes, investing in a fiberglass clarifier system is a step toward a cleaner, more sustainable future.