-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 14, 2025 07:41

Back to list

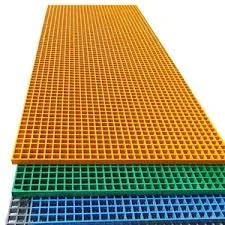

fiberglass cover

Fiberglass covers have emerged as an indispensable element in various industries, owing to their unique blend of reliability, durability, and versatility. At their core, these covers serve as protective barriers that enhance the longevity and performance of numerous applications. Crafted meticulously from interwoven glass fibers and resin, fiberglass covers are engineered to withstand extreme conditions, positioning them as the go-to solution for businesses aiming to optimize safety and functionality.

In terms of safety, fiberglass covers offer an additional advantage with their inherent non-conductive properties. This makes them an ideal choice in electrical applications where contact with conductive materials can pose significant risks. Their non-conductivity levels alleviate concerns over electric shocks, thereby increasing safety for workers and reducing liability for businesses. When evaluated through a lens of performance and protection, fiberglass covers also excel in their ability to withstand aggressive chemical exposure. They effectively protect against threats such as acids, alkalis, and solvents, which otherwise compromise the integrity of lesser materials. This robustness ensures a prolonged lifespan, granting assurances that the initial investment reaps benefits over an extended period. An often-overlooked aspect of fiberglass covers is their ability to attenuate noise. In industrial settings where sound pollution poses both a distraction and a potential health hazard, these covers help reduce noise levels, contributing to a more serene and productive working environment. Industry leaders emphasizing innovation and resilience have long recognized the multiplicative advantages of fiberglass covers. As these covers adapt to fulfill the diverse needs of emerging technologies and applications, their importance is set to skyrocket further. For industries ranging from marine to automotive, and from construction to telecommunications, embracing fiberglass covers is not simply an enhancement; it is an evolution. In conclusion, the utility, durability, and adaptability of fiberglass covers position them as a cornerstone of modern industrial practice. As companies strategize toward futures laden with technological advancements and environmental accountability, the role of fiberglass covers will undoubtedly increase in prominence. The decision to integrate fiberglass covers into your business operations is a testament to a commitment to excellence and is an investment in reliability and innovation. This lays the groundwork for not only meeting current demands but exceeding them, ensuring a competitive edge in today’s dynamic marketplace.

In terms of safety, fiberglass covers offer an additional advantage with their inherent non-conductive properties. This makes them an ideal choice in electrical applications where contact with conductive materials can pose significant risks. Their non-conductivity levels alleviate concerns over electric shocks, thereby increasing safety for workers and reducing liability for businesses. When evaluated through a lens of performance and protection, fiberglass covers also excel in their ability to withstand aggressive chemical exposure. They effectively protect against threats such as acids, alkalis, and solvents, which otherwise compromise the integrity of lesser materials. This robustness ensures a prolonged lifespan, granting assurances that the initial investment reaps benefits over an extended period. An often-overlooked aspect of fiberglass covers is their ability to attenuate noise. In industrial settings where sound pollution poses both a distraction and a potential health hazard, these covers help reduce noise levels, contributing to a more serene and productive working environment. Industry leaders emphasizing innovation and resilience have long recognized the multiplicative advantages of fiberglass covers. As these covers adapt to fulfill the diverse needs of emerging technologies and applications, their importance is set to skyrocket further. For industries ranging from marine to automotive, and from construction to telecommunications, embracing fiberglass covers is not simply an enhancement; it is an evolution. In conclusion, the utility, durability, and adaptability of fiberglass covers position them as a cornerstone of modern industrial practice. As companies strategize toward futures laden with technological advancements and environmental accountability, the role of fiberglass covers will undoubtedly increase in prominence. The decision to integrate fiberglass covers into your business operations is a testament to a commitment to excellence and is an investment in reliability and innovation. This lays the groundwork for not only meeting current demands but exceeding them, ensuring a competitive edge in today’s dynamic marketplace.

Next:

Related Products