-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

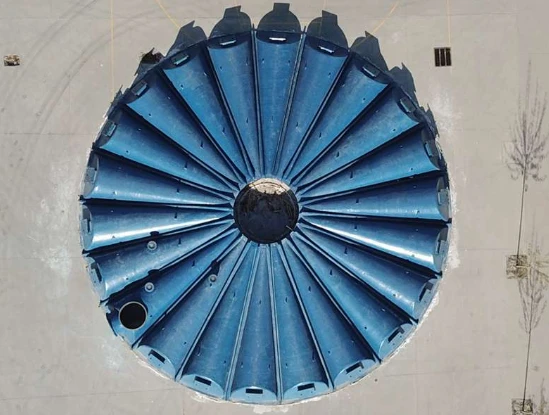

Exploring the Key Features of Food Grade Fiberglass Equipment for Safety and Efficiency

Fiberglass Food Grade Equipment A Closer Look at Its Features and Benefits

In the food industry, maintaining hygiene and safety standards is paramount. This is where fiberglass food grade equipment comes into play. Comprising a mixture of glass fibers and resin, fiberglass is increasingly being used in food processing and handling. This article delves into the features and advantages of fiberglass food grade equipment, exploring why it is becoming a popular choice among food manufacturers.

Durability and Strength

One of the standout features of fiberglass food grade equipment is its remarkable durability. Unlike traditional materials like wood or metal, fiberglass does not corrode, rust, or rot, making it an ideal choice for environments where moisture and cleaning are prevalent. Its strength allows it to withstand significant impact and stress, which is essential in busy food production settings where equipment may be subjected to heavy use.

Additionally, fiberglass can be formulated to manage extreme temperatures, making it suitable for both hot and cold food processing

. The ability to resist thermal shock ensures that fiberglass equipment maintains its structural integrity, thereby promoting a longer lifespan compared to other materials.Hygienic Properties

Hygiene is crucial in the food industry, and fiberglass food grade equipment excels in this regard. It features a non-porous surface that prevents the absorption of bacteria, mold, and other pathogens. This characteristic significantly reduces the risk of contamination, a vital factor when dealing with food products. The smooth surfaces of fiberglass are easy to clean and sanitize, meeting the stringent hygiene regulations required in food processing areas.

Moreover, fiberglass is resistant to many chemicals, including acids and alkalis, so it can withstand various cleaning agents without degrading. This feature is particularly important in food facilities that utilize aggressive cleaning protocols to maintain sanitation.

fiberglass food grade equipment a closer look at its features and

Weight and Mobility

Another notable advantage of fiberglass food grade equipment is its lightweight nature. Compared to metal alternatives, fiberglass is significantly lighter, which facilitates easier handling and transport. This aspect makes it ideal for facilities that frequently rearrange their layout or require mobile equipment. The reduced weight also lowers transportation costs when moving equipment between locations or transporting it for maintenance.

Customization Options

Fiberglass equipment can be tailored to specific needs, providing versatile design options that are not easily achievable with other materials. Manufacturers can customize equipment shapes, sizes, and colors, contributing to efficient production workflows and enhancing brand identity. Customization can also meet unique processing needs, ensuring that equipment perfectly fits the facility's requirements.

Cost-Effectiveness

While the initial investment in fiberglass food grade equipment may be higher than conventional materials, its long-term benefits far outweigh the costs. The durability and reduced maintenance needs lead to cost savings over time. With fiberglass's resistance to wear and tear, companies can expect lower replacement rates, which further enhances its overall cost-effectiveness.

Conclusion

In conclusion, fiberglass food grade equipment presents a myriad of features that make it an excellent choice for the food industry. Its durability, hygienic properties, lightweight characteristics, customizability, and cost-effectiveness position it as a suitable solution for modern food processing challenges. As food safety regulations continue to evolve, and as the industry seeks innovative materials that support sanitation and efficiency, fiberglass stands out as a highly reliable option. Embracing this advanced technology can help food manufacturers not only comply with standards but also enhance their operational effectiveness and product integrity.