-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Performance Fiberglass Solutions for Extreme Temperature Applications

Fiberglass Products for High Temperature Applications

Fiberglass, also known as glass-reinforced plastic (GRP), is a composite material made of a plastic matrix reinforced by fine glass fibers. Due to its unique properties, fiberglass has become a popular choice for various applications, particularly those involving high-temperature environments. Its lightweight nature, high strength-to-weight ratio, and excellent thermal resistance make fiberglass an ideal solution for industries such as aerospace, automotive, construction, and electrical insulation.

Properties of Fiberglass at High Temperatures

One of the most significant advantages of fiberglass when exposed to high temperatures is its ability to maintain structural integrity. Unlike many traditional materials that may warp or degrade under thermal stress, fiberglass can withstand extreme heat without losing its mechanical properties. Typically, fiberglass can resist temperatures up to 500°F (approximately 260°C). Certain specialized formulations can even endure higher temperatures, making them suitable for applications in furnace linings, exhaust systems, and other high-heat environments.

Moreover, fiberglass is inherently non-combustible, which adds to its appeal in safety-sensitive applications. When exposed to flames or extreme heat, fiberglass does not ignite or emit harmful fumes, reducing fire risks in both residential and industrial settings.

Types of Fiberglass Products for High Temperatures

Several types of fiberglass products are designed to withstand high-temperature conditions. Some of the most common include

1. Fiberglass Insulation Fiberglass insulation is widely used in buildings and industrial settings to improve energy efficiency and provide thermal protection. High-temperature insulation batts and blankets are specifically engineered to withstand elevated temperatures without losing effectiveness. These products are essential in insulation applications around boilers, ovens, and kilns.

2. Fiberglass Fabrics These fabrics are utilized in various applications, ranging from protective clothing for workers in high-temperature environments to components in thermal management systems. Fabrics infused with silicone or other heat-resistant coatings enhance their durability and thermal insulation capabilities, making them ideal for protective gear in industries such as metalworking and foundries.

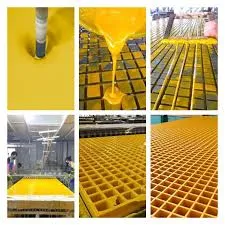

fiberglass products for high temperature

3. Fiberglass Reinforced Plastics (FRP) FRP composites are utilized in areas where both structural strength and high-temperature resistance are required. These materials find applications in tanks, piping systems, and structural components in chemical processing plants. Their corrosion resistance in addition to thermal stability makes them suitable for containing hot chemicals.

4. Gaskets and Seals High-temperature fiberglass gaskets and seals are crucial for maintaining the integrity of joints in machinery and equipment subjected to thermal fluctuations. They prevent leaks and ensure that components remain sealed under pressure and stress.

5. Heat Shields and Barriers Fiberglass heat shields are designed to protect sensitive components from excessive heat exposure. These shields are commonly used in automotive applications to protect critical parts of the engine and exhaust systems from heat damage.

The Advantages of Using Fiberglass in High-Temperature Applications

The use of fiberglass materials in high-temperature settings offers several advantages

- Lightweight and Durable Fiberglass products are lighter than metal counterparts, thus reducing overall equipment weight without compromising strength. - Corrosion Resistance Fiberglass does not corrode like metals, which is particularly beneficial in chemical processing applications where exposure to harsh substances is common. - Cost-Effective While the initial investment may be higher than traditional materials, the longevity and low maintenance of fiberglass products often result in lower overall lifetime costs. - Versatility Fiberglass can be molded into various shapes and sizes, offering flexibility in design, which is essential for custom applications in specific high-temperature environments.

Conclusion

Fiberglass products tailored for high-temperature applications have established themselves as indispensable in a variety of industries. Their robust thermal resistance, lightweight nature, and safety characteristics position them as superior alternatives to traditional materials. As technology continues to advance, we can expect to see even more innovative uses of fiberglass in high-heat contexts, ultimately enhancing efficiency, safety, and performance across numerous sectors.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025