-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

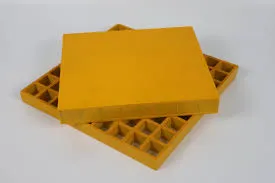

Safe Storage Solutions for FRP Chemical Tanks in Industrial Applications

The Importance of FRP Chemical Storage Tanks in Modern Industry

In today's industrial landscape, the safe and efficient storage of chemicals plays a pivotal role in maintaining operational productivity while ensuring environmental safety. One solution that has gained significant traction in recent years is the use of Fiberglass Reinforced Plastic (FRP) chemical storage tanks. These tanks present numerous advantages over traditional materials, making them a preferred choice for many industries.

FRP storage tanks are composed of a composite material, primarily made from a polymer matrix reinforced with fibrous materials. This combination makes FRP tanks incredibly strong, yet lightweight, offering excellent resistance to a wide range of chemicals. Unlike metal tanks, which can corrode over time, FRP tanks are not susceptible to rust or degradation when exposed to harsh chemicals, thereby extending their lifespan and reducing maintenance costs.

The Importance of FRP Chemical Storage Tanks in Modern Industry

Furthermore, the lightweight nature of FRP tanks allows for easier installation and transportation. Unlike heavy steel tanks, which often require specialized equipment for handling and positioning, FRP tanks can be moved with greater ease. This not only reduces labor costs but also minimizes the potential for accidents during installation.

frp chemical storage tanks

Environmental concerns are at the forefront of industrial operations today, and FRP tanks align with sustainability goals. Their long lifespan reduces the frequency of replacements and the associated waste generated. Additionally, the non-corrosive properties minimize the risk of leaks, which could lead to soil and water contamination. By investing in FRP storage solutions, companies can bolster their environmental responsibility while maintaining compliance with stringent regulations.

Moreover, FRP tanks are highly customizable, allowing manufacturers to tailor designs according to specific operational needs. They can be produced in various sizes and shapes, making them suitable for a wide range of applications. From small-scale operations to large industrial facilities, FRP tanks can be adapted to fit a company’s unique requirements.

Another advantage of FRP chemical storage tanks is their thermal insulation properties. Many chemicals require specific temperature controls to maintain stability and efficacy. The insulating capabilities of FRP tanks can help to stabilize internal temperatures, potentially reducing energy costs associated with heating or cooling systems.

In addition to their practical benefits, FRP tanks are also designed with safety in mind. Many modern FRP tanks come equipped with advanced features such as overfill protection, level sensors, and secondary containment systems. These safety measures are crucial in preventing potential spills and leaks, protecting both personnel and the environment.

In conclusion, FRP chemical storage tanks represent a significant advancement in the way industries approach chemical storage. Their unique combination of chemical resistance, lightweight design, environmental sustainability, customizability, and safety features make them an ideal choice for modern industrial applications. As companies continue to prioritize safety and efficiency, the adoption of FRP tanks is likely to grow, heralding a new era in chemical storage solutions. By choosing FRP, industries not only enhance their operational capabilities but also contribute to a safer and more sustainable future.

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025