-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

FRP Chimney Design and Installation for Industrial Applications and Environmental Compliance

FRP Chimney Construction and Installation for Industrial Applications

In contemporary industrial environments, the need for efficient and sustainable chimney systems has never been more pressing. Among the various materials available, Fiberglass Reinforced Plastic (FRP) has emerged as a preferred choice for chimney construction and installation. This article outlines the advantages, construction processes, and installation considerations for FRP chimneys in industrial settings.

Advantages of FRP Chimneys

FRP chimneys offer several significant benefits that make them suitable for industrial applications

1. Corrosion Resistance One of the most critical advantages of FRP is its excellent resistance to corrosion. In industries where emissions may consist of aggressive chemicals or high-temperature gases, traditional materials like steel and concrete can degrade over time. FRP’s resistance to chemicals ensures a longer lifespan, reducing maintenance costs and downtime.

2. Lightweight Compared to conventional materials, FRP is considerably lighter, which simplifies transportation and reduces structural support requirements. This lightweight nature not only decreases the installation costs but also lowers the overall structural load on facilities.

3. Design Flexibility FRP can be molded into various shapes and sizes, allowing for custom designs that can meet specific industrial needs. This flexibility ensures that the chimney can be tailored for aesthetic appeal and functional efficiency.

4. Thermal Insulation FRP provides excellent thermal insulation, helping to maintain the temperature of gases as they exit the system. This characteristic enhances energy efficiency and reduces the risk of heat-related damages or hazards.

5. Durability FRP materials have a strong resistance to environmental factors, including UV radiation and moisture, which can compromise other materials over time. This durability makes FRP chimneys an excellent long-term investment for industrial operations.

Construction Process

The construction of FRP chimneys typically follows a series of structured steps that ensure quality and compliance with industrial standards

1. Design Phase Initial planning involves understanding the specific needs of the industrial facility, including emission types, temperature ranges, and space constraints. Engineers will develop a detailed design that meets safety and operational requirements.

2. Material Selection Choosing the right type of FRP composite is crucial. The material must be suited for the specific gases and chemicals to which it will be exposed. Options may include different resin systems that offer varying degrees of resistance to acids, alkalis, and solvents.

frp chimney construction and installation for industrial and ...

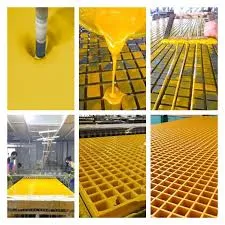

3. Fabrication Using advanced fabrication techniques, such as filament winding or hand layup methods, components of the chimney are constructed. Each layer is carefully applied to achieve the desired thickness and strength.

4. Quality Control During fabrication, stringent quality control measures are implemented to ensure that the FRP components meet performance specifications. Inspectors verify resin integrity, fiberglass layering, and overall structural quality.

5. Pre-Installation Testing Before installation, it is essential to conduct tests to check for any cracks or defects in the FRP materials. Such proactive measures save time and resources in the long run.

Installation Considerations

Installation of FRP chimneys requires careful planning and execution to ensure safety and functionality

1. Site Preparation The installation site must be prepared to support the new chimney structure. This includes ensuring stable foundations and access for machinery that will aid in the installation process.

2. Cranes and Lifting Equipment Given the height and weight of FRP chimney sections, specialized cranes and lifting equipment are often necessary. Proper rigging methods must be used to avoid damage during the lifting process.

3. Sealing Joints Proper sealing of joints during installation is critical to prevent leakage and maintain the integrity of the chimney. High-quality sealants specifically designed for FRP should be used to ensure a durable connection.

4. Ventilation and Safety Measures Throughout the installation process, safety measures should be enforced to protect workers from potential hazards related to height and equipment.

5. Post-Installation Testing Once installed, the chimney system should undergo rigorous testing to verify operational efficiency and safety standards. This may include pressure tests and thermal inspections.

Conclusion

FRP chimney construction and installation in industrial applications provide a robust solution to meet the demanding requirements of modern industries. Their advantages in terms of durability, corrosion resistance, and design flexibility make them an invaluable asset to any facility. With careful planning and execution, FRP chimneys can significantly improve operational efficiency and longevity, proving beneficial for both the environment and the bottom line. As industries continue to embrace sustainable practices, FRP technology stands poised to play an integral role in achieving these goals.