-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

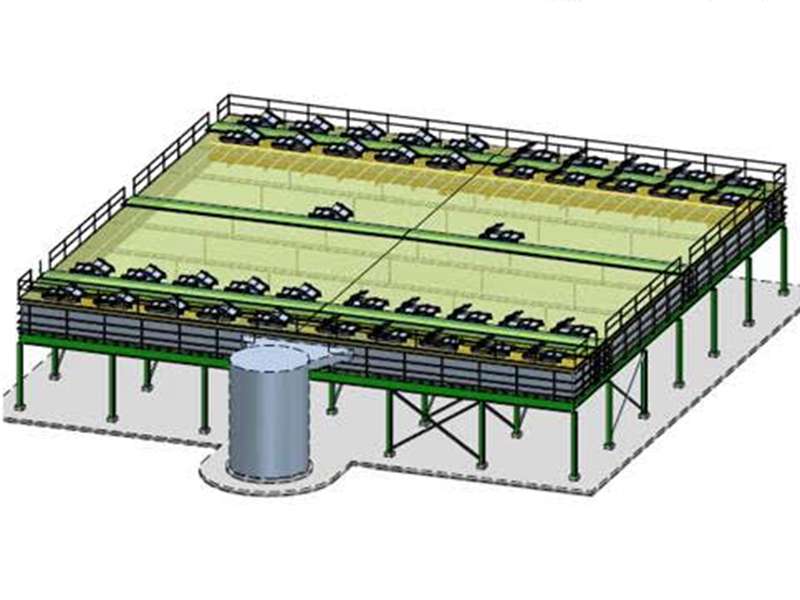

frp moisture trap

Understanding the Importance of FRP Moisture Traps in Modern Applications

In various industrial applications, managing moisture is crucial to maintaining the integrity and longevity of equipment, structures, and processes. Fiberglass Reinforced Plastic (FRP) moisture traps have emerged as a vital solution in this regard, offering both efficiency and resilience in combating the detrimental effects of moisture.

FRP moisture traps are designed to capture and contain moisture, preventing it from infiltrating sensitive areas. This technology leverages the lightweight yet robust characteristics of fiberglass, making it an ideal material for creating effective moisture control systems. The unique properties of FRP ensure that these traps are not only durable but also resistant to corrosion, making them suitable for various environments, including those with high humidity and chemical exposure.

Understanding the Importance of FRP Moisture Traps in Modern Applications

In addition to protecting equipment and infrastructure, FRP moisture traps also play a critical role in maintaining product quality. In manufacturing processes, especially in food and beverage, pharmaceuticals, and electronics, the presence of moisture can compromise product integrity. For instance, the absorption of water can lead to mold growth, spoilage, or even chemical reactions that can ruin finished products. By effectively capturing moisture, FRP traps help maintain a controlled environment, ensuring that products meet quality standards and are safe for consumption or use.

frp moisture trap

Moreover, the versatility of FRP moisture traps makes them suitable for various applications. They can be used in commercial buildings, factories, wastewater treatment plants, and even in residential settings. Their adaptability to different environments allows for tailored solutions based on specific moisture control needs. Whether installed in ventilation systems, ducts, or directly within equipment, FRP moisture traps effectively manage moisture levels while maintaining airflow.

Furthermore, the lightweight nature of FRP allows for easy installation, reducing labor costs and time associated with setup. Traditional moisture management systems often involve heavy materials and complex structures, which can be cumbersome and expensive to install. In contrast, FRP moisture traps can be integrated seamlessly into existing systems, enhancing functionality without requiring significant modifications.

Another aspect to consider is the environmental impact of moisture control solutions. FRP materials are increasingly being designed with sustainability in mind. Many manufacturers are adopting eco-friendly practices, using recycled materials or minimizing waste in production processes. This focus on sustainability not only benefits the environment but also resonates with businesses seeking to improve their corporate social responsibility.

Lastly, regular maintenance of FRP moisture traps is essential to ensure their effectiveness. While these traps are built to withstand various challenges, periodic checks and cleaning are necessary to remove any accumulated moisture and debris. Implementing a maintenance routine can further enhance the durability and performance of these systems.

In conclusion, FRP moisture traps represent a sophisticated solution to address moisture-related challenges across multiple industries. Their ability to protect equipment, ensure product quality, and adapt to diverse environments makes them an invaluable asset in modern operations. As industries continue to evolve and seek efficient approaches to moisture management, FRP moisture traps will undoubtedly play a pivotal role in safeguarding assets, enhancing productivity, and promoting sustainability.