-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

frp products for thermal and nuclear power

FRP Products for Thermal and Nuclear Power A Comprehensive Overview

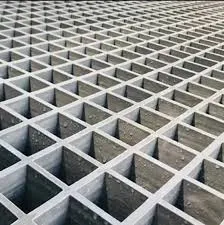

Fiber Reinforced Plastics (FRP) have emerged as vital materials in the energy sector, particularly in thermal and nuclear power plants

. Their unique properties, such as high strength-to-weight ratios, resistance to corrosion, and excellent thermal insulation, make FRP products integral to enhancing the efficiency and safety of energy production systems.In thermal power stations, FRP composites are used extensively in components that require durability and resistance to aggressive environments. The heat exchangers, which play a crucial role in energy conversion, often experience extreme temperatures and corrosive conditions. Traditional materials, such as metals, can suffer from oxidation and scaling, leading to reduced efficiency and higher maintenance costs. In contrast, FRP can withstand harsh conditions without significant degradation, thus prolonging the service life of heat exchangers and reducing downtime.

Additionally, FRP is employed in constructing piping systems in thermal plants. Its lightweight nature facilitates easier installation and reduces overall structural load, making it an attractive alternative to conventional piping materials. Furthermore, FRP’s resistance to chemical corrosion minimizes the risks of leaks and failures, ensuring the integrity of the power generation process.

frp products for thermal and nuclear power

In the realm of nuclear power, the use of FRP products is paramount for both safety and operational efficiency. The containment structures that protect against radiation leakage benefit significantly from FRP composites, which can be designed to meet stringent regulatory demands while maintaining structural integrity. The ability of FRP to withstand radiation without deteriorating over time enhances safety measures in nuclear facilities, providing peace of mind to operators and the surrounding communities.

Insulation is another essential application of FRP in nuclear power plants. The material’s thermal resistance properties help maintain optimal operating temperatures for various systems, reducing energy consumption and improving overall efficiency. Effective insulation also contributes to worker safety by minimizing heat exposure in critical operational areas.

Moreover, as sustainability becomes a priority in energy production, FRP products align well with green initiatives. Their longevity and recyclability reduce waste and the environmental impact associated with frequent replacements of conventional materials.

In conclusion, FRP products hold a significant position in the thermal and nuclear power sectors due to their superior performance characteristics. As the energy landscape continues to evolve, the integration of advanced materials like FRP will be crucial in enhancing efficiency, safety, and sustainability in power generation. This innovation not only supports current technological demands but also paves the way for future advancements in energy production.