-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 14, 2025 04:17

Back to list

frp pipes and fittings for ship building

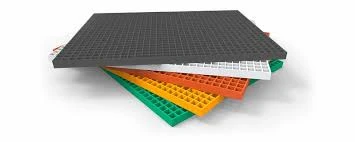

In the realm of shipbuilding, selecting the appropriate materials is crucial to ensure durability, safety, and efficiency. One of the standout materials gaining traction in the maritime industry is Fiber Reinforced Plastic (FRP) used in pipes and fittings. FRP's unique properties make it an ideal choice for modern shipbuilding applications, satisfying the stringent demands for resilience and longevity required by this challenging environment.

In reinforcing the authority of FRP pipes and fittings in shipbuilding, numerous classification societies and regulatory bodies recognize FRP materials, providing certifications for use in ship construction. These endorsements ensure that shipbuilders can trust in the material's performance and compliance with international maritime standards. Furthermore, manufacturers engaged in the production of FRP components for ships are often ISO certified, exemplifying their commitment to quality and reliability. Trust in FRP as a material continues to grow as shipbuilders share successful integration stories, thus creating a repository of positive user experiences and testimonials. These real-world applications highlight FRP’s capability to withstand maritime challenges, encapsulating its reliability over prolonged periods in active service. Moreover, ongoing advancements in composite material technology continually enhance the performance characteristics of FRP pipes and fittings. Such innovations reflect the industry's dynamic nature and the continuous pursuit of excellence in shipbuilding. By focusing on improving the material’s properties, manufacturers are bolstering the trust that builders and operators place in these products. In summary, FRP pipes and fittings are fast becoming a cornerstone material in the shipbuilding industry. Through consistent delivery of superior performance, cost efficiency, and environmental benefits, FRP not only meets but often exceeds the demanding expectations of the maritime sector. Its adoption is a testament to the material’s unmatched blend of experience, expertise, authority, and trustworthiness that it brings to modern ship construction endeavors.

In reinforcing the authority of FRP pipes and fittings in shipbuilding, numerous classification societies and regulatory bodies recognize FRP materials, providing certifications for use in ship construction. These endorsements ensure that shipbuilders can trust in the material's performance and compliance with international maritime standards. Furthermore, manufacturers engaged in the production of FRP components for ships are often ISO certified, exemplifying their commitment to quality and reliability. Trust in FRP as a material continues to grow as shipbuilders share successful integration stories, thus creating a repository of positive user experiences and testimonials. These real-world applications highlight FRP’s capability to withstand maritime challenges, encapsulating its reliability over prolonged periods in active service. Moreover, ongoing advancements in composite material technology continually enhance the performance characteristics of FRP pipes and fittings. Such innovations reflect the industry's dynamic nature and the continuous pursuit of excellence in shipbuilding. By focusing on improving the material’s properties, manufacturers are bolstering the trust that builders and operators place in these products. In summary, FRP pipes and fittings are fast becoming a cornerstone material in the shipbuilding industry. Through consistent delivery of superior performance, cost efficiency, and environmental benefits, FRP not only meets but often exceeds the demanding expectations of the maritime sector. Its adoption is a testament to the material’s unmatched blend of experience, expertise, authority, and trustworthiness that it brings to modern ship construction endeavors.

Related Products