-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 30, 2025 02:41

Back to list

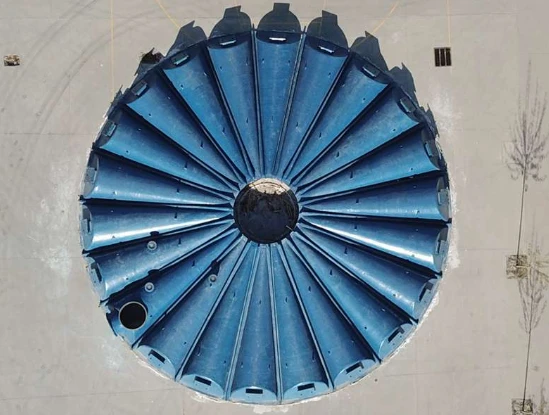

frp products for thermal and nuclear power

FRP (Fiber Reinforced Plastic) products have emerged as revolutionary solutions in the thermal and nuclear power sectors. With growing demands for efficient, durable, and safe power generation systems, FRP offers an unparalleled combination of benefits that elevate its status in these critical industries.

The eco-friendly aspect of FRP products cannot be overlooked. With a growing emphasis on sustainable and green solutions, FRP aligns with global environmental goals. Unlike traditional materials that might require extensive energy to produce and process, FRP manufacturing is relatively energy-efficient and results in a lower carbon footprint. Additionally, FRP materials can be recycled, complementing initiatives to reduce waste and promote sustainable resource management within power generation domains. However, the successful integration of FRP products into thermal and nuclear power plants relies heavily on expertise. The production of FRP requires a comprehensive understanding of material properties, plant requirements, and engineering capabilities. Partnering with experienced manufacturers and suppliers who possess a proven track record in the power sector ensures that the products meet the rigorous standards and certifications required. These partnerships are pivotal in assuring plant operators about the reliability and safety of their infrastructure. To bolster the credibility and authority of FRP products in the industry, it's crucial to focus on data-driven results and case studies. Comprehensive assessments and documented successes in various power plants serve as powerful endorsements. By showcasing real-world applications where FRP has resolved specific challenges, potential adopters can be confident in their decision to implement these advanced materials. In conclusion, FRP products present a compelling case for their use in thermal and nuclear power sectors. Their unmatched resistance to corrosive elements, versatile application potential, and contribution to sustainable practices make them indispensable. As power generation continues to evolve, the expertise and trustworthiness of FRP providers will play a vital role in advancing these industries towards a safer and more efficient future. With a continuous emphasis on innovation and material science, FRP remains at the forefront of engineered solutions, driving progress in the power sector.

The eco-friendly aspect of FRP products cannot be overlooked. With a growing emphasis on sustainable and green solutions, FRP aligns with global environmental goals. Unlike traditional materials that might require extensive energy to produce and process, FRP manufacturing is relatively energy-efficient and results in a lower carbon footprint. Additionally, FRP materials can be recycled, complementing initiatives to reduce waste and promote sustainable resource management within power generation domains. However, the successful integration of FRP products into thermal and nuclear power plants relies heavily on expertise. The production of FRP requires a comprehensive understanding of material properties, plant requirements, and engineering capabilities. Partnering with experienced manufacturers and suppliers who possess a proven track record in the power sector ensures that the products meet the rigorous standards and certifications required. These partnerships are pivotal in assuring plant operators about the reliability and safety of their infrastructure. To bolster the credibility and authority of FRP products in the industry, it's crucial to focus on data-driven results and case studies. Comprehensive assessments and documented successes in various power plants serve as powerful endorsements. By showcasing real-world applications where FRP has resolved specific challenges, potential adopters can be confident in their decision to implement these advanced materials. In conclusion, FRP products present a compelling case for their use in thermal and nuclear power sectors. Their unmatched resistance to corrosive elements, versatile application potential, and contribution to sustainable practices make them indispensable. As power generation continues to evolve, the expertise and trustworthiness of FRP providers will play a vital role in advancing these industries towards a safer and more efficient future. With a continuous emphasis on innovation and material science, FRP remains at the forefront of engineered solutions, driving progress in the power sector.

Related Products