-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 28, 2025 02:40

Back to list

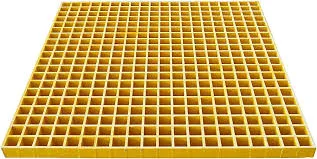

frp shell

In the domain of industrial and commercial applications, the term 'FRP shell' is gaining notable recognition for its multifaceted use and powerful properties. As an expert in the field of product design and material innovation, I am eager to share insights based on extensive experience with Fiber-Reinforced Plastics (FRP), thus underscoring their technical advantages, durability, and reliability.

Furthermore, the design versatility of FRP shells cannot be overstated. With the ability to mold into complex shapes and sizes, FRP allows for precise customization in line with specific application requirements. This flexibility supports innovative designs and solutions that standard materials cannot replicate. In architecture, for instance, the application of FRP shells offers architects unprecedented creative freedom while ensuring the safety and longevity of the structures. Clients and industries continue to express high trust levels in FRP shells due to their proven track record in diverse applications. This trust is supported by authoritative reviews and certifications that affirm the reliability and performance of these materials under various conditions. In introducing FRP shells into your industrial or commercial projects, you are not only leveraging a material praised for its experience-backed efficiency and durability but also aligning with a product that demonstrates unparalleled expertise and authoritativeness in meeting the most demanding specifications. Whether enhancing existing systems or innovatively approaching new projects, the incorporation of FRP shells is undoubtedly a step toward future-focused and sustainable solutions. In conclusion, the remarkable properties of FRP shells—weight reduction, corrosion resistance, thermal and electrical insulation, and design flexibility—are transforming industries by providing an authoritative, trustworthy, and innovative alternative to traditional materials. As a longstanding expert in the field, I fully endorse the incorporation of FRP shells, confident that they will deliver substantial, measurable benefits across diverse applications, ensuring your projects are robust, efficient, and future-ready.

Furthermore, the design versatility of FRP shells cannot be overstated. With the ability to mold into complex shapes and sizes, FRP allows for precise customization in line with specific application requirements. This flexibility supports innovative designs and solutions that standard materials cannot replicate. In architecture, for instance, the application of FRP shells offers architects unprecedented creative freedom while ensuring the safety and longevity of the structures. Clients and industries continue to express high trust levels in FRP shells due to their proven track record in diverse applications. This trust is supported by authoritative reviews and certifications that affirm the reliability and performance of these materials under various conditions. In introducing FRP shells into your industrial or commercial projects, you are not only leveraging a material praised for its experience-backed efficiency and durability but also aligning with a product that demonstrates unparalleled expertise and authoritativeness in meeting the most demanding specifications. Whether enhancing existing systems or innovatively approaching new projects, the incorporation of FRP shells is undoubtedly a step toward future-focused and sustainable solutions. In conclusion, the remarkable properties of FRP shells—weight reduction, corrosion resistance, thermal and electrical insulation, and design flexibility—are transforming industries by providing an authoritative, trustworthy, and innovative alternative to traditional materials. As a longstanding expert in the field, I fully endorse the incorporation of FRP shells, confident that they will deliver substantial, measurable benefits across diverse applications, ensuring your projects are robust, efficient, and future-ready.

Next:

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025