Gratings & Covers – Anti-Slip, Heavy-Duty, Custom Sizes

Field Notes on Industrial Gratings: What’s Working Now

If you handle corrosive floors, trench runs, or marine catwalks, you’ve likely bumped into Gratings & Covers as a problem-solver more than once. I’ve walked plenty of plants where old steel is rusting out and production managers just want something that doesn’t become a maintenance line item every quarter. FRP molded panels—especially open mesh and covered types—are, frankly, having a moment.

What’s driving the trend

Two things: safety and chemistry. Coarse-grit surfaces keep traction even when it’s a wet Monday shift; corrosion resistance beats out painted steel in brine, caustic wash, and many acids. To be honest, many customers say they switched after one too many shutdowns for spot repairs. In wastewater, pulp & paper, and food plants, it’s become almost standard fare. The origin of this particular product line is No. 1289, Yingbin South Street, Jizhou District, Hengshui, Hebei, China—yes, the FRP belt runs strong there.

Quick spec snapshot (molded FRP)

| Parameter | Typical Value (≈, real-world use may vary) |

|---|---|

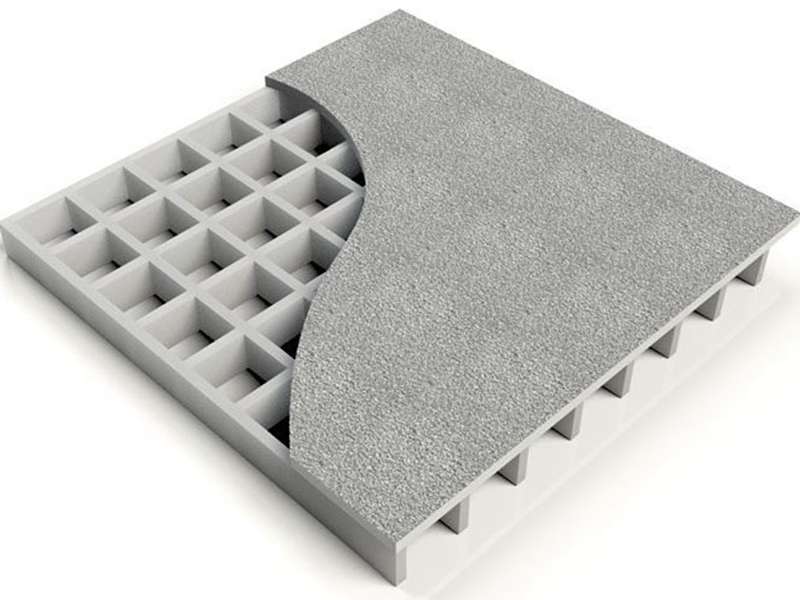

| Type | Open mesh panel & covered panel (integral plate) |

| Resin systems | Vinyl ester (VE), Isophthalic polyester (ISO), Orthophthalic (O) |

| Mesh/Thickness | 25–38 mm thick; common mesh 38×38 mm; covers 3–6 mm plate |

| Flexural strength | ≈ 150–220 MPa (ASTM D790) |

| Flame spread | ≤ 25 (ASTM E84, selected resins) |

| Chemical resistance | Per ASTM C581, VE shows best acid/alkali performance |

| Slip resistance | Grit top; wet DCOF ≈ 0.6+ |

| Service life | 20–30 years in typical corrosive duty, with inspections |

Where they fit

- Chemical processing floors, sumps, neutralization rooms

- Wastewater walkways, aeration basins, odor-control Gratings & Covers

- Marine docks, offshore platforms, splash zones

- Food plants (non-sparking, non-conductive options)

- Power, mining, and pulp & paper access ways

Process flow (how it’s built)

Materials: E-glass rovings + thermoset resin (VE/ISO) with UV inhibitors. Methods: molded in heated open molds; for covered panels, plate is co-molded for a monolithic bond. Post-processing: cut-to-size, edge banding, gritting. Testing: flexural (ASTM D790), flame (ASTM E84), combustibility (ASTM D635), chemical soak (ASTM C581). QC: ISO 9001 production records. Service life is tracked via periodic visual and tap inspections—nothing exotic, but it works.

Advantages I see in the field

- Corrosion resistance vs. galvanized steel, especially near chlorine/NaOH

- Lightweight for rooftop and retrofit work—less crane time

- Non-sparking, electrically non-conductive (handy around instrumentation)

- Covered Gratings & Covers help with odor control and small-parts drop prevention

Vendor landscape (quick compare)

| Vendor | Core Material | Lead Time (≈) | Certifications | Price Level | Notes |

|---|---|---|---|---|---|

| Jrain Gratings & Covers | Molded FRP (VE/ISO) | 2–5 weeks | ISO 9001; third‑party fire/chem tests | $ | Strong in custom colors and covered panels |

| Global Composite Co. | Molded & pultruded FRP | 3–6 weeks | ISO 9001, E84 | $$ | Broader pultruded spans |

| Steel Fabricator Inc. | Galv. steel grating | 1–3 weeks | A36/galv. specs | $–$$ | Great for high point loads; needs corrosion care |

Customization

Cut-to-size, edge banding, gritted or smooth top, conductive/anti-static options, color coding (yellow for safety lines is common), and load-matched thickness. Covered Gratings & Covers can be perforated or sealed for odor abatement.

Mini case notes

Wastewater plant, Midwest US: Replaced rusted bar grating on aeration basin bridges with VE molded FRP; reported 0 safety slips over 18 months and zero corrosion touch-ups. Ops manager’s words: “Install went fast, and we forgot about it—that’s good.”

Chemical blending room, SEA: Covered Gratings & Covers over trenches reduced odor carry-over and tool drop incidents by “noticeable margin,” according to maintenance.

Compliance and safety

Specify slip resistance per facility policy and keep walkways clear to meet OSHA walking-working surface rules. For fire performance, check resin selection against the required ASTM E84 rating. Chemical compatibility should be validated with soak data (ASTM C581) for the actual media—lab sheets help, but field trials are gold.

References

Latest news

-

Rectangular Tank Made of Fiberglass Material – Durable, Cost-Effective Liquid Storage SolutionsNewsNov.24,2025

-

Hollow Drill Rods for Efficient Drilling Operations in the Field | Durable, Lightweight & CustomNewsNov.23,2025

-

Powerful yt27 Rock Drill for Tough Mining Surfaces | Durable & PortableNewsNov.23,2025

-

Why the Reversible Drill Bit Is a Versatile Tool for All Your Drilling NeedsNewsNov.22,2025

-

Fiberglass Food Grade Equipment: Key Features, Benefits & Global ImpactNewsNov.22,2025

-

How a Drilling Rod Spirals Down Into the Earth: Tech, Trends & Global ImpactNewsNov.21,2025