Gratings & Covers for Industry—Anti-Slip, Corrosion-Proof?

Gratings & Covers: field notes, specs, and what buyers really ask

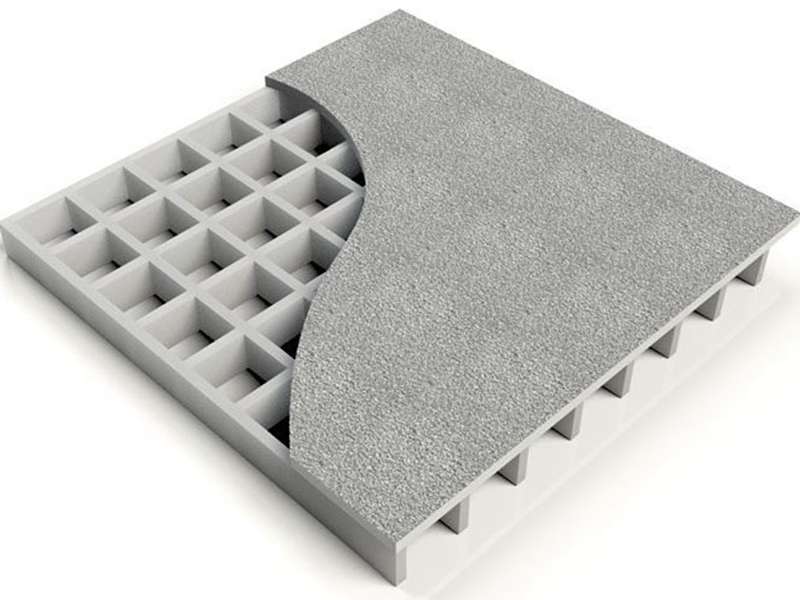

If you work around corrosive chemicals or wet floors (most of us do, one way or another), you’ve probably heard about Gratings & Covers. I’ve toured factories from Hebei to Houston, and honestly, the category matured fast. The latest molded FRP panels are tough, light, and surprisingly comfortable underfoot—especially when you add that gritty anti-slip. Jrain, out of No. 1289, Yingbin South Street, Jizhou District, Hengshui, Hebei, China, has been pushing practical details that maintenance teams keep mentioning.

What’s trending (and what isn’t)

Steel still has its place, but operators are switching to Gratings & Covers for corrosion resistance, slip safety, and lower total cost. Resin systems got smarter: isophthalic for balanced performance, vinyl ester for heavy chemical duty. UV-stable pigments and grit surfaces became standard. Also, specifiers care about real test data—not brochure claims—so ASTM and ISO test references are table stakes now.

Applications I keep seeing

- Chemical plants, plating shops, and wastewater walkways

- Marine docks, offshore skids, splash zones

- Food & beverage and pulp & paper areas needing frequent washdowns

- Power plants, cooling towers, and substation trenches

- Oil & gas refineries, onshore skids, and cable trench Gratings & Covers

Process flow and technical backbone

Materials: E-glass roving/mat + thermoset resin (isophthalic or vinyl ester), UV inhibitors, pigment, and aluminum oxide grit for covered tops. Methods: Molded one-piece lattice (open panel) or laminated plate over grating (covered panel). Cured in heated molds, then post-cured, trimmed, and grit-coated. Testing: ASTM D790 (flexural), D543 (chemical), E84 (flame spread; Class 1 achievable), D635 (self-extinguishing), D2583 (Barcol hardness). Slip per ANSI/NFSI B101 or equivalent; wet COF ≈ 0.6–0.8 depending on grit. Service life: around 20–30 years in typical industrial exposure; real-world use may vary with UV and chemical load.

Representative product specifications

| Parameter | Typical Value (≈) | Notes |

|---|---|---|

| Panel type | Open & covered | Molded FRP grating or plate-covered grating |

| Thickness | 25–50 mm | Other sizes on request |

| Mesh / open area | 38×38 mm; 60–70% open | Varies with mold |

| Resin options | ISO / VE | Isophthalic or vinyl ester |

| Flexural strength | ≈ 220–350 MPa | ASTM D790 |

| Flame spread | Class 1 | ASTM E84 (with fire-retardant resin) |

Vendor comparison (real buyer questions)

| Criteria | Jrain | Competitor A | Competitor B |

|---|---|---|---|

| Resin portfolio | ISO / VE, FR options | ISO only | ISO / VE |

| UV + grit longevity | High; alumina grit bonded | Medium | High |

| Certs & reports | ISO 9001; ASTM test reports | Basic COC | ISO 9001 |

| Lead time (≈) | 2–4 weeks | 4–6 weeks | 3–5 weeks |

Customization, install, and feedback

Cut-to-size, toe plates, embedded grit, covered panels for cable trenches, and color-coding (yellow hazard zones) are common asks. Hardware: stainless M-clips, J-bolts, and hold-downs per OSHA walking-working surfaces. Many customers say the switch cut maintenance by 20–30%—less rust, fewer slip incidents. One Southeast Asia wastewater plant replaced steel with Gratings & Covers across 1,800 m²; after 12 months they logged zero coating touch-ups and COF stayed >0.65 in wet tests.

Why this matters

It’s not just corrosion. It’s downtime, safety KPIs, and capex that doesn’t boomerang back as opex. With proper resin choice and verified test data, molded FRP becomes the boringly reliable choice—which, I guess, is exactly what you want in a walkway.

Standards and compliance snapshot

- ASTM D790, D543, D635, E84; Barcol per D2583

- Slip resistance per ANSI/NFSI B101 or equivalent; target wet COF ≥ 0.6

- Quality system: ISO 9001:2015

- OSHA 1910.22 walking-working surfaces (layout, drainage, securement)

References

- ASTM International – D790, D543, D635, E84, D2583 standards overview: https://www.astm.org/

- ANSI/NFSI B101 Slip Resistance resources: https://www.nfsi.org/

- ISO 9001:2015 Quality Management Systems: https://www.iso.org/standard/62085.html

- OSHA 1910.22 Walking-Working Surfaces: https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.22

Latest news

-

Rectangular Tank Made of Fiberglass Material – Durable, Cost-Effective Liquid Storage SolutionsNewsNov.24,2025

-

Hollow Drill Rods for Efficient Drilling Operations in the Field | Durable, Lightweight & CustomNewsNov.23,2025

-

Powerful yt27 Rock Drill for Tough Mining Surfaces | Durable & PortableNewsNov.23,2025

-

Why the Reversible Drill Bit Is a Versatile Tool for All Your Drilling NeedsNewsNov.22,2025

-

Fiberglass Food Grade Equipment: Key Features, Benefits & Global ImpactNewsNov.22,2025

-

How a Drilling Rod Spirals Down Into the Earth: Tech, Trends & Global ImpactNewsNov.21,2025