-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Generating a Similar Title Related to GRP Car in Under 15 Words

Understanding GRP and Its Importance in the Automotive Industry

The automotive industry is continuously evolving, with manufacturers vying to produce vehicles that are not only innovative but also meet the growing demands for sustainability and efficiency. One of the materials that has gained prominence in this sector is Glass Reinforced Plastic (GRP), also known as fiberglass. This composite material is celebrated for its unique properties, making it a popular choice for various automotive applications.

What is GRP?

Glass Reinforced Plastic consists of a polymer matrix reinforced with glass fibers. The combination results in a lightweight material that boasts high tensile strength and excellent resistance to corrosion, chemicals, and weathering. Due to its flexibility in design and manufacturing processes, GRP can be molded into various shapes and sizes, allowing for creativity in automotive design that traditional materials may not facilitate.

Advantages of GRP in Automotive Applications

1. Weight Reduction One of the most significant advantages of using GRP in automotive manufacturing is its lightweight nature. Reducing the weight of a vehicle can lead to improved fuel efficiency and reduced emissions. This is crucial in meeting the stringent environmental regulations that are becoming standard worldwide.

2. Durability and Longevity GRP is highly resistant to corrosion and degradation, which translates to a longer lifespan for automotive components. This durability not only enhances the vehicle's performance but also reduces maintenance costs for manufacturers and consumers alike.

3. Design Flexibility GRP can be easily molded into complex shapes and structures, allowing automotive designers to innovate freely without previously encountered constraints. This flexibility paves the way for aesthetically pleasing designs that can enhance a vehicle's appeal in a competitive market.

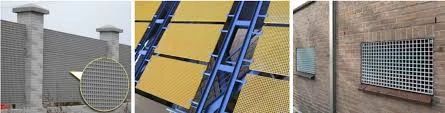

grp car

4. Cost Efficiency Although GRP can have a higher initial cost compared to some traditional materials, its durability and low maintenance requirements can offset these initial expenses over time. Additionally, the efficiency during the manufacturing process provides an economic advantage.

5. Thermal and Electrical Insulation GRP offers excellent insulative properties, making it suitable for various automotive applications where heat and electricity management are critical. This is particularly relevant in electric vehicles, where efficient thermal management is vital for battery life and overall performance.

Challenges Facing GRP Adoption

Despite its numerous advantages, the adoption of GRP in the automotive industry does face some challenges. Manufacturers need to manage the recycling and disposal of GRP products, as the environmental impact of fiberglass waste remains a concern. Additionally, the production process for GRP can be more complex compared to traditional materials, requiring specialized knowledge and equipment.

Future Prospects

The automotive industry is on the brink of a revolution, with increased emphasis on sustainability and efficiency. As manufacturers seek alternatives to traditional materials like steel and aluminum, GRP presents a compelling option. Innovations in technology are likely to enhance the manufacturing processes and improve the recyclability of GRP, further solidifying its place as a key material in the automotive sector.

In conclusion, Glass Reinforced Plastic is poised to play an impactful role in the future of automotive design and manufacturing. Its lightweight, durable, and flexible nature makes GRP an attractive material for meeting the demands of a modern automotive market that prioritizes performance, safety, and environmental responsibility. As the industry continues to innovate, GRP will undoubtedly remain at the forefront of material technology in the quest to build better, greener vehicles.