-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

grp duct system

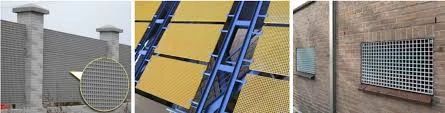

Understanding the GRP Duct System An Overview

In modern construction and HVAC (Heating, Ventilation, and Air Conditioning) systems, the choice of materials and design plays a crucial role in ensuring efficiency and sustainability. One such innovative solution gaining traction in various applications is the GRP duct system. GRP, an abbreviation for Glass Reinforced Plastic, is a composite material that combines fiberglass with a resin, resulting in a lightweight, durable, and corrosion-resistant solution. This article explores the characteristics, benefits, applications, and advantages of GRP duct systems.

Characteristics of GRP Duct Systems

GRP duct systems stand out for their unique physical and chemical properties. Firstly, the lightweight nature of GRP allows for easy handling and installation, reducing labor costs and simplifying the logistics of transport and installation on-site. Secondly, the material is resistant to corrosion, making it suitable for harsh environments, including chemical plants, wastewater treatment facilities, and coastal areas. Furthermore, GRP ducts exhibit excellent thermal insulation properties, which help maintain the temperature of air and fluids transported through them.

Another significant characteristic of GRP is its ability to be molded into various shapes and sizes. This flexibility enables designers to create tailored duct systems that fit specific project requirements, maximizing space efficiency and improving airflow.

Benefits of GRP Duct Systems

One of the most compelling benefits of GRP duct systems is their longevity. Unlike traditional materials such as metal— which can rust and corrode over time— GRP's resistance to degradation ensures that these duct systems have a longer lifespan, resulting in lower maintenance costs. Additionally, the non-conductive nature of GRP prevents condensation from forming on the exterior of the ducts, which can be a significant issue in metal duct systems, leading to potential water damage and mold growth.

grp duct system

Moreover, GRP is an environmentally friendly option. The material can be produced and manufactured with a lower carbon footprint compared to steel or aluminum. Furthermore, GRP duct systems are often fully recyclable at the end of their life cycle, promoting sustainability in construction and reducing waste in landfills.

Applications of GRP Duct Systems

The versatility of GRP duct systems allows them to be utilized in a variety of applications. They are commonly found in industrial settings, where durable and corrosion-resistant materials are necessary due to exposure to chemicals and harsh environments. Additionally, these ducts are increasingly used in commercial buildings, hospitals, and educational institutions due to their lightweight yet strong structure, ensuring efficient air distribution without overloading the building framework.

GRP duct systems also find relevance in agricultural applications, such as in climate-controlled greenhouses, where precise airflow is essential for crop production. Moreover, they are employed in marine applications, contributing to ventilation and air conditioning systems on ships and offshore platforms.

Conclusion

In summary, the GRP duct system offers numerous advantages that make it a leading choice for modern construction and HVAC applications. With its lightweight and corrosion-resistant properties, it not only enhances efficiency and lowers maintenance needs but also supports sustainable building practices. The adaptability of GRP to various environmental conditions and applications further solidifies its status as a durable and reliable solution for managing airflow in diverse settings. As the demand for innovative building materials continues to grow, GRP duct systems are poised to play an essential role in advancing both industrial and commercial infrastructure while fostering a commitment to sustainability. By embracing this technology, builders and engineers can contribute to a more efficient and environmentally responsible future.