-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 21, 2025 01:06

Back to list

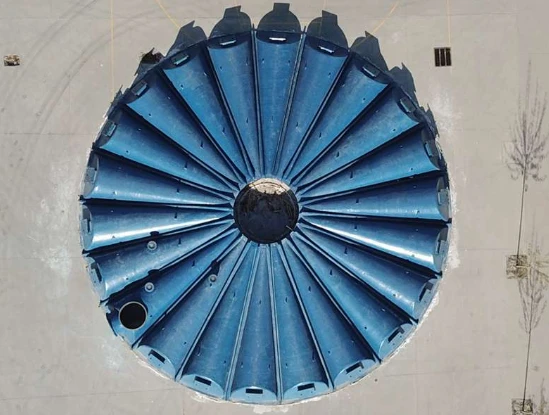

mining rock extension rod

Mining rock extension rods are the unsung heroes of the drilling and mining industry. These essential components provide the necessary reach and stability to drill further and deeper into the earth, ensuring that miners can access rich mineral deposits safely and efficiently. Having spent extensive years in the drilling industry, my firsthand experience highlights the critical factors to consider when selecting mining rock extension rods that deliver optimum performance and reliability.

The surface finish and anti-corrosion treatments that rods undergo are especially crucial in preventing premature failure due to rust and other forms of environmental degradation. Zinc plating and epoxy coatings are popular treatments that extend the rods' service life, particularly in operations involving exposure to moisture or saline conditions. In an offshore drilling project in the Gulf of Mexico, rods coated with specialized anti-corrosion layers demonstrated remarkable longevity, cutting replacement expenses substantially. Reputable suppliers not only vouch for the quality of their extension rods but also provide robust after-sales support, ensuring tools function as expected. A partnership with a manufacturer that offers comprehensive warranties and responsive technical assistance amplifies trust and operational success. In my own experience, working with companies that incorporate regular feedback for product improvements led to a significant reduction in tool failures, ensuring a smooth, uninterrupted mining process. Sustainability is emerging as a pivotal consideration in mining operations, making it worth mentioning that innovations in rod manufacturing are geared towards environmentally friendly practices. Some leading manufacturers are pioneering techniques to recycle metal shavings post-production, thus greatly minimizing waste. As sustainability continues to shape industry standards, preference for environmentally conscious products is likely to grow, paving the way for more eco-friendly mining operations. In summary, mining rock extension rods might seem like mere mechanical components, but their role in ensuring successful drilling operations cannot be underestimated. By focusing on quality materials, precision engineering, proper sizing, advanced surface treatments, dependable supplier relationships, and sustainability, operators can harness the full potential of these rods. For anyone invested in optimizing their mining processes, understanding these factors not only contributes to better performance and reliability but also positions an operation for long-term success and adherence to emerging industry standards.

The surface finish and anti-corrosion treatments that rods undergo are especially crucial in preventing premature failure due to rust and other forms of environmental degradation. Zinc plating and epoxy coatings are popular treatments that extend the rods' service life, particularly in operations involving exposure to moisture or saline conditions. In an offshore drilling project in the Gulf of Mexico, rods coated with specialized anti-corrosion layers demonstrated remarkable longevity, cutting replacement expenses substantially. Reputable suppliers not only vouch for the quality of their extension rods but also provide robust after-sales support, ensuring tools function as expected. A partnership with a manufacturer that offers comprehensive warranties and responsive technical assistance amplifies trust and operational success. In my own experience, working with companies that incorporate regular feedback for product improvements led to a significant reduction in tool failures, ensuring a smooth, uninterrupted mining process. Sustainability is emerging as a pivotal consideration in mining operations, making it worth mentioning that innovations in rod manufacturing are geared towards environmentally friendly practices. Some leading manufacturers are pioneering techniques to recycle metal shavings post-production, thus greatly minimizing waste. As sustainability continues to shape industry standards, preference for environmentally conscious products is likely to grow, paving the way for more eco-friendly mining operations. In summary, mining rock extension rods might seem like mere mechanical components, but their role in ensuring successful drilling operations cannot be underestimated. By focusing on quality materials, precision engineering, proper sizing, advanced surface treatments, dependable supplier relationships, and sustainability, operators can harness the full potential of these rods. For anyone invested in optimizing their mining processes, understanding these factors not only contributes to better performance and reliability but also positions an operation for long-term success and adherence to emerging industry standards.

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025