Need Clear Steps? Create Step-by-Step Guides with AI

Field Notes on Steps: FRP stair treads that outlast the job

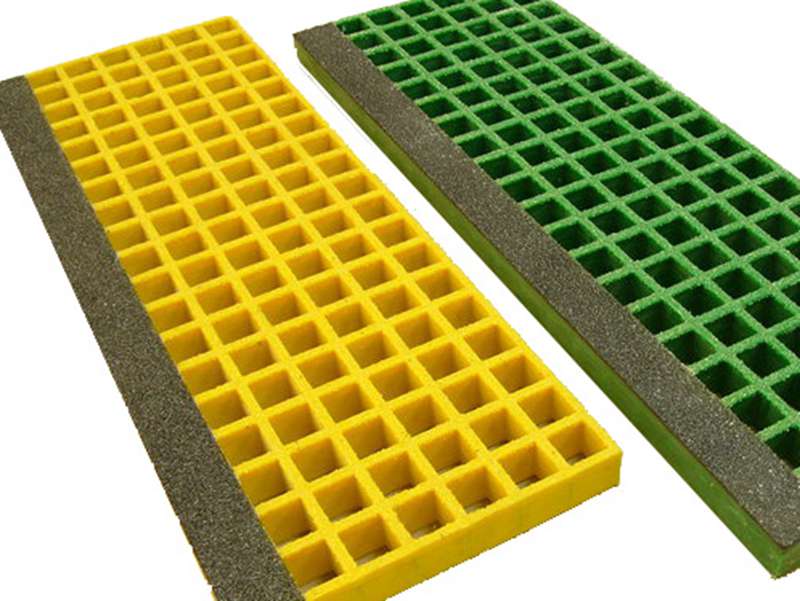

A few months back I walked the shop floor in Jizhou District, Hengshui—No. 1289, Yingbin South Street to be precise—where these fiberglass stair treads are made. The crew had that calm confidence you only see in plants that ship globally week after week. And to be honest, it shows in the product. Steps are molded FRP grating treads with a gritted, anti-slip surface; they don’t need paint, shrug off corrosion, and install without a small crane. Many customers say they basically forget them after commissioning—and that’s kind of the point.

Industry trends (and why FRP won)

Across chemical processing, wastewater, and coastal infrastructure, specifiers have pivoted from galvanized steel to FRP. Reasons aren’t mysterious: tighter safety standards on slip resistance, relentless chloride exposure, and lifecycle cost models that finally count downtime. Steps ride this wave: lighter than steel, immune to rot, and far kinder to maintenance budgets.

Technical snapshot and real-world specs

| Type | Molded FRP stair tread panels with gritted top; optional pultruded nosing |

| Resin systems | ISO polyester (general), vinyl ester (corrosive/chemical), phenolic (fire-critical) |

| Standard sizes | Tread depth ≈ 225–305 mm; thickness 30–38 mm; panel width up to 1,220 mm (custom cuts available) |

| Surface | Silica grit anti-slip (coarse or medium); contrasting nosing optional |

| Load/Span | Typical span 750–1,000 mm at L/200 deflection; design to ASTM D790 data (site loads vary) |

| Fire & UV | ASTM E84 Class 1, ASTM D635 self-extinguishing; UV inhibitors and veil |

| Service life | 20–30 years in typical industrial exposure (real-world use may vary) |

Process, testing, and the nitty‑gritty

Materials: E-glass rovings + resin (ISO/VE) with UV veil. Methods: grid is molded in corrosion-resistant tooling; grit is broadcast and embedded during cure; nosing can be pultruded and bonded. QC: Barcol hardness checks, fiber/resin ratio verification, and dimensional tolerances on every lot. Testing: flexural per ASTM D790; tensile per ASTM D638; flame spread per ASTM E84; water absorption ASTM D570; slip resistance to ANSI A326.3 or ASTM D2047 (COF dry ≈ 0.8–1.0; wet ≈ 0.6–0.8).

Where Steps shine

- Chemical plants and pickling lines (acid fumes don’t scare FRP)

- Wastewater and desalination decks—constant spray, constant grip

- Marine/offshore walkdowns; power gen scrubber access

- Food plants (non-sparking, easy washdown, no paint flakes)

Vendor landscape (what buyers compare)

| Vendor | Lead Time | Certs | Customization | Typical Cost |

|---|---|---|---|---|

| JRain FRP (Hebei, China) | ≈ 2–4 weeks + transit | ISO 9001; ASTM/OSHA compliance docs | Cut-to-fit, nosing color, hardware kits | Competitive FOB |

| Local Fabricator (metal) | 1–2 weeks | AISC shop; no FRP fire data | High; but corrosion-prone | Lower upfront, higher lifecycle |

| Global FRP Brand | 3–6 weeks | Broad third-party test library | Wide palette; premium pricing | Highest |

Customization and installation

Pick resin by chemistry (vinyl ester for acids), grit grade by footwear, and nosing color for OSHA visibility. JRain ships Steps pre-cut, drilled if you want, with stainless clips/bolts. Two techs and a cordless set can rig a staircase before lunch, no heavy lifting device required.

Case studies and feedback

Wastewater, coastal city: Replaced rusted steel treads; COF stayed ≥0.7 wet after 12 months; zero repainting. Supervisor told me, “We finally stopped babysitting the stairs.”

Galvanizing line, APAC: Vinyl ester Steps held up to acid mist; annual shutdown inspection noted no blistering; deflection under 2 mm at 900 mm span with 2 kN point load.

Compliance, safety, and paperwork

- Design around OSHA 1910 walking-working surfaces for stair geometry

- Fire per ASTM E84; self-extinguishing per ASTM D635

- Slip testing to ANSI A326.3/ASTM D2047; documentation on request

- Factory quality system: ISO 9001; third-party test summaries available

Citations:

1) ASTM D790, D638, D570, D635, E84 – American Society for Testing and Materials.

2) OSHA 29 CFR 1910 – Walking-Working Surfaces, U.S. Occupational Safety and Health Administration.

3) ANSI A326.3 – Dynamical Coefficient of Friction for hard surfaces; applicability guidance for gritted FRP.

4) ISO 9001:2015 – Quality management systems.

Latest news

-

Rectangular Tank Made of Fiberglass Material – Durable, Cost-Effective Liquid Storage SolutionsNewsNov.24,2025

-

Hollow Drill Rods for Efficient Drilling Operations in the Field | Durable, Lightweight & CustomNewsNov.23,2025

-

Powerful yt27 Rock Drill for Tough Mining Surfaces | Durable & PortableNewsNov.23,2025

-

Why the Reversible Drill Bit Is a Versatile Tool for All Your Drilling NeedsNewsNov.22,2025

-

Fiberglass Food Grade Equipment: Key Features, Benefits & Global ImpactNewsNov.22,2025

-

How a Drilling Rod Spirals Down Into the Earth: Tech, Trends & Global ImpactNewsNov.21,2025