-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 23, 2025 05:12

Back to list

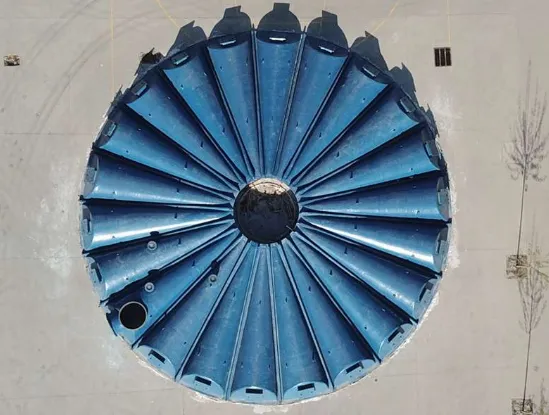

Large Size Field Tanks

Designing a rectangular tank involves careful consideration to ensure optimal functionality and durability, especially for those looking to calculate using GRP (Glass Reinforced Plastic) materials. GRP has emerged as a preferred choice for constructing tanks due to its inherent advantages such as corrosion resistance, lightweight nature, and notable strength. Here, we delve into the nuances of designing a rectangular tank with specific dimensions, highlighting the expertise and trustworthiness in material selection, engineering, and installation.

Installation also plays a crucial role in the overall performance of a GRP rectangular tank. Trustworthy installation practices ensure that the tank functions as designed, maintaining its resistance to leaks and structural failures. This involves precise alignment and securing methods, especially in applications where the tank might be subjected to dynamic loads or changes in temperature. Skilled professionals equipped with experience in handling GRP materials can mitigate risks associated with improper installation, thus safeguarding investment and operational efficiency. As sustainability becomes an increasingly pivotal consideration, GRP stands out due to its long lifecycle and reduced environmental impact compared to traditional materials like steel or concrete. It requires less maintenance and seldom suffers corrosion, reducing the need for frequent repairs or replacements. Moreover, GRP tanks can be recycled at the end of their life span, aligning with environmental conservation goals and industry regulations. Leveraging these attributes, businesses can not only satisfy their operational necessities but significantly cut down on long-term costs associated with maintenance and downtimes. Additionally, selecting a reputable manufacturer ensures that the product adheres to the highest quality and safety standards, further reinforcing the trust between the provider and end-user. In conclusion, designing a rectangular tank with GRP involves a seamless blend of expert design strategies, authoritative material choice, and reliable installation practices. By understanding and applying these principles, businesses can ensure that their tanks provide lasting performance while promoting innovative, sustainable practices within their industries. The resulting operational efficacy and cost savings underscore the essentiality of incorporating both expertise and trust into the GRP tank fabrication and installation process.

Installation also plays a crucial role in the overall performance of a GRP rectangular tank. Trustworthy installation practices ensure that the tank functions as designed, maintaining its resistance to leaks and structural failures. This involves precise alignment and securing methods, especially in applications where the tank might be subjected to dynamic loads or changes in temperature. Skilled professionals equipped with experience in handling GRP materials can mitigate risks associated with improper installation, thus safeguarding investment and operational efficiency. As sustainability becomes an increasingly pivotal consideration, GRP stands out due to its long lifecycle and reduced environmental impact compared to traditional materials like steel or concrete. It requires less maintenance and seldom suffers corrosion, reducing the need for frequent repairs or replacements. Moreover, GRP tanks can be recycled at the end of their life span, aligning with environmental conservation goals and industry regulations. Leveraging these attributes, businesses can not only satisfy their operational necessities but significantly cut down on long-term costs associated with maintenance and downtimes. Additionally, selecting a reputable manufacturer ensures that the product adheres to the highest quality and safety standards, further reinforcing the trust between the provider and end-user. In conclusion, designing a rectangular tank with GRP involves a seamless blend of expert design strategies, authoritative material choice, and reliable installation practices. By understanding and applying these principles, businesses can ensure that their tanks provide lasting performance while promoting innovative, sustainable practices within their industries. The resulting operational efficacy and cost savings underscore the essentiality of incorporating both expertise and trust into the GRP tank fabrication and installation process.

Next:

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025