-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 13, 2025 13:56

Back to list

Steps

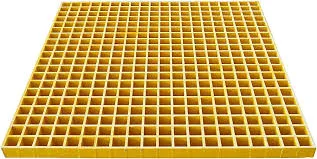

In the realm of steel smelting, the integration of innovative materials has ushered in a new era of efficiency and safety. FRP (Fiber Reinforced Plastic) products have emerged as a pivotal component for steel smelting plants, offering a blend of durability, resistance, and reliability that traditional materials simply cannot match. This article delves into the unique advantages of FRP products, showcasing their indispensable role in enhancing steel production processes.

Furthermore, the longevity of FRP materials translates to reduced maintenance costs. The inherent resistance of FRP to rust, chemicals, and abrasion means that components last longer and require less frequent replacement or repairs. This not only saves money over the lifecycle of the plant but also minimizes interruptions to production schedules, ensuring a smoother and more predictable operational flow. In terms of safety, the non-conductive nature of FRP products offers a significant advantage in steel smelting environments, where the risk of electrical hazards is high. By mitigating the danger of electrical conductivity, FRP products contribute to creating a safer working environment for plant personnel, which is paramount in maintaining high standards of occupational health and safety. From a sustainability perspective, the use of FRP products aligns with the steel industry's move towards more environmentally responsible practices. FRP's resistance to chemical decay means fewer pollutants are released into the atmosphere, and its durability means less frequent replacements, leading to reduced waste generation. Plants adopting FRP solutions can thereby enhance their environmental stewardship, appealing to environmentally-conscious stakeholders and customers alike. In conclusion, the incorporation of FRP products into steel smelting plant operations offers a multifaceted approach to addressing the challenges faced by the industry. With proven benefits in terms of durability, cost efficiency, safety, and sustainability, FRP products are not merely substitutes for traditional materials but rather transformative solutions that can redefine operational standards. As steel smelting plants continue to strive for enhanced performance and reduced environmental impact, the adoption of FRP products is set to become an integral aspect of strategic growth and innovation.

Furthermore, the longevity of FRP materials translates to reduced maintenance costs. The inherent resistance of FRP to rust, chemicals, and abrasion means that components last longer and require less frequent replacement or repairs. This not only saves money over the lifecycle of the plant but also minimizes interruptions to production schedules, ensuring a smoother and more predictable operational flow. In terms of safety, the non-conductive nature of FRP products offers a significant advantage in steel smelting environments, where the risk of electrical hazards is high. By mitigating the danger of electrical conductivity, FRP products contribute to creating a safer working environment for plant personnel, which is paramount in maintaining high standards of occupational health and safety. From a sustainability perspective, the use of FRP products aligns with the steel industry's move towards more environmentally responsible practices. FRP's resistance to chemical decay means fewer pollutants are released into the atmosphere, and its durability means less frequent replacements, leading to reduced waste generation. Plants adopting FRP solutions can thereby enhance their environmental stewardship, appealing to environmentally-conscious stakeholders and customers alike. In conclusion, the incorporation of FRP products into steel smelting plant operations offers a multifaceted approach to addressing the challenges faced by the industry. With proven benefits in terms of durability, cost efficiency, safety, and sustainability, FRP products are not merely substitutes for traditional materials but rather transformative solutions that can redefine operational standards. As steel smelting plants continue to strive for enhanced performance and reduced environmental impact, the adoption of FRP products is set to become an integral aspect of strategic growth and innovation.

Next:

Related Products