-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 24, 2025 02:10

Back to list

tools for drilling through rock in tunnels, specifically designed ...

In the evolving landscape of tunnel construction, the tools designed for drilling through rock play an indispensable role in ensuring efficiency and safety. These tools are refined through years of research, blended with practical experience in the field. This article delves into some of the most sophisticated drilling tools tailored for rocky terrains, highlighting their impacts and contributions to tunnel engineering.

The use of diamond-tipped drill bits is another advancement. These bits are gaining popularity for their exceptional durability and efficiency in penetrating the hardest types of rock. They offer a longer lifespan and a cleaner cut, which translates into significant cost savings and higher productivity over time. Moreover, the reduced need for changing tool heads increases operational uptime, a factor critical in maintaining the momentum necessary for timely project completion. Hydraulic rock drills also merit attention, combining high-speed rotation with powerful percussion to effectively break through hard rock surfaces. Their compact design makes them suitable for smaller tunnel diameters, while their sophisticated control systems allow for precision drilling. With reduced vibration levels, these drills enhance user safety and comfort, an often overlooked but vital aspect of operational efficiency. Trust in these technologies has been bolstered by extensive field testing and expert endorsements, reinforcing their authoritative standing in the industry. Professionals who operate these tools have provided invaluable feedback, helping manufacturers refine their designs to better meet the demands of real-world conditions. This collaboration between manufacturers and industry experts has been critical in fostering trust and ensuring that products not only meet but exceed safety and performance standards. In conclusion, the selection of the right tools for drilling through rock in tunnels is vital for the success of any project. By leveraging advanced technologies and expertise in the field, companies can drive forward impressive efficiencies, reduced costs, and enhanced safety. The advancements in tunnel drilling tools underscore not just engineering prowess but also a commitment to optimizing the construction process, ensuring projects are delivered on time, within budget, and to the highest quality standards.

The use of diamond-tipped drill bits is another advancement. These bits are gaining popularity for their exceptional durability and efficiency in penetrating the hardest types of rock. They offer a longer lifespan and a cleaner cut, which translates into significant cost savings and higher productivity over time. Moreover, the reduced need for changing tool heads increases operational uptime, a factor critical in maintaining the momentum necessary for timely project completion. Hydraulic rock drills also merit attention, combining high-speed rotation with powerful percussion to effectively break through hard rock surfaces. Their compact design makes them suitable for smaller tunnel diameters, while their sophisticated control systems allow for precision drilling. With reduced vibration levels, these drills enhance user safety and comfort, an often overlooked but vital aspect of operational efficiency. Trust in these technologies has been bolstered by extensive field testing and expert endorsements, reinforcing their authoritative standing in the industry. Professionals who operate these tools have provided invaluable feedback, helping manufacturers refine their designs to better meet the demands of real-world conditions. This collaboration between manufacturers and industry experts has been critical in fostering trust and ensuring that products not only meet but exceed safety and performance standards. In conclusion, the selection of the right tools for drilling through rock in tunnels is vital for the success of any project. By leveraging advanced technologies and expertise in the field, companies can drive forward impressive efficiencies, reduced costs, and enhanced safety. The advancements in tunnel drilling tools underscore not just engineering prowess but also a commitment to optimizing the construction process, ensuring projects are delivered on time, within budget, and to the highest quality standards.

Related Products

Latest news

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

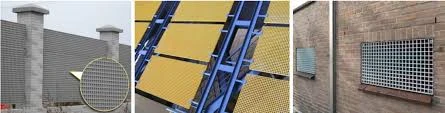

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025

-

Tapered Drill String Design Guide Durable Performance & UsesNewsJun.09,2025