-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 13, 2025 04:31

Back to list

Car and Boat Body

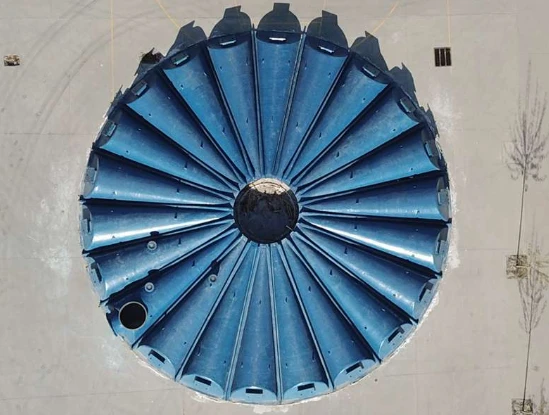

The advancement of technology in the sphere of tunnel construction has revolutionized methods for drilling through rock. This process, inherently complex and demanding, requires tools specifically designed to address the unique challenges posed by varied rock formations. Selecting appropriate drilling tools plays a pivotal role in enhancing operational efficiency and achieving optimal outcomes. Here, we delve into an insightful overview spotlighting the foremost tools designed for these challenging conditions, integrating professional insights and authoritative knowledge to reinforce trustworthiness.

Furthermore, adopting advanced drilling fluids is paramount to optimizing the drilling process. These fluids not only facilitate cooling and lubrication during drilling but also aid in stabilizing the tunnel face, preventing collapses, and managing debris. The selection of appropriate drilling fluids, customized to the geological conditions, contributes significantly to the efficiency and safety of tunnel construction projects. Incorporating intelligent drilling systems represents a leap forward in the domain of rock drilling within tunnels. These systems employ sensors and automated controls to monitor and adjust drilling parameters in real time, ensuring optimal performance. By continuously analyzing data on rock properties and drilling conditions, intelligent systems enhance decision-making, improve accuracy, and reduce the margin for human error. The integration of such technologies exemplifies the industry's shift towards smart, data-driven operations that prioritize precision and safety. The trustworthiness of these advanced tools is validated by rigorous testing and compliance with international safety standards. Manufacturers invest extensively in research and development to innovate solutions that meet the growing demands of modern tunnel construction. Collaborations with engineering experts and geologists further reinforce the reliability and effectiveness of these tools, ensuring they are well-equipped to tackle the diverse challenges encountered in various tunnel environments. In conclusion, leveraging technologically advanced tools specifically designed for drilling through rock in tunnels is essential for achieving success in contemporary tunnel construction projects. The synergy between tools like TBMs and rock drills, supported by intelligent systems and high-quality materials, underscores the need for a strategic approach in tool selection. By prioritizing expertise, authority, and trustworthiness in the development and application of these tools, stakeholders in the tunnel construction industry can ensure the successful completion of projects, even in the most demanding geological conditions.

Furthermore, adopting advanced drilling fluids is paramount to optimizing the drilling process. These fluids not only facilitate cooling and lubrication during drilling but also aid in stabilizing the tunnel face, preventing collapses, and managing debris. The selection of appropriate drilling fluids, customized to the geological conditions, contributes significantly to the efficiency and safety of tunnel construction projects. Incorporating intelligent drilling systems represents a leap forward in the domain of rock drilling within tunnels. These systems employ sensors and automated controls to monitor and adjust drilling parameters in real time, ensuring optimal performance. By continuously analyzing data on rock properties and drilling conditions, intelligent systems enhance decision-making, improve accuracy, and reduce the margin for human error. The integration of such technologies exemplifies the industry's shift towards smart, data-driven operations that prioritize precision and safety. The trustworthiness of these advanced tools is validated by rigorous testing and compliance with international safety standards. Manufacturers invest extensively in research and development to innovate solutions that meet the growing demands of modern tunnel construction. Collaborations with engineering experts and geologists further reinforce the reliability and effectiveness of these tools, ensuring they are well-equipped to tackle the diverse challenges encountered in various tunnel environments. In conclusion, leveraging technologically advanced tools specifically designed for drilling through rock in tunnels is essential for achieving success in contemporary tunnel construction projects. The synergy between tools like TBMs and rock drills, supported by intelligent systems and high-quality materials, underscores the need for a strategic approach in tool selection. By prioritizing expertise, authority, and trustworthiness in the development and application of these tools, stakeholders in the tunnel construction industry can ensure the successful completion of projects, even in the most demanding geological conditions.

Next:

Related Products