-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 17, 2025 14:38

Back to list

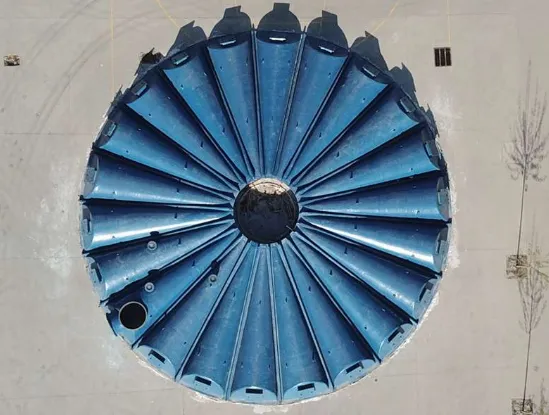

Clarifiers & Settlers

Fiberglass stacks represent a significant advancement in industrial exhaust and emission control systems. Crafted from finely woven glass fibers bonded with resin, these stacks offer unparalleled benefits in terms of efficiency and durability, standing out in a competitive market of emission solutions.

A critical component of fiberglass stack success lies in their customization capabilities. Manufacturers can tailor dimensions, shapes, and configurations to cater to specific industrial needs, ensuring a precise match to operational requirements. This adaptability is crucial for facilities operating under unique spatial or production challenges, providing a bespoke solution that enhances operational efficiency and compliance with environmental standards. Trustworthiness is intrinsically linked to the proven track record of fiberglass stacks in various applications worldwide. Companies adopting this technology often report a marked improvement in system reliability and compliance with emission regulations. Testimonials from industry professionals further reinforce this trustworthiness, as they share firsthand accounts of reduced downtime and maintenance costs as a direct result of implementing fiberglass solutions. The environmental impact of using fiberglass stacks cannot be overstated. Unlike metal equivalents that may contribute to excessive resource extraction and energy-intensive manufacturing processes, fiberglass production is relatively energy-efficient. Additionally, fiberglass stacks can be recycled, making them a sustainable choice in the broader narrative of environmentally conscious manufacturing practices. This aligns with the growing corporate trend of adopting greener technologies that resonate with environmentally aware stakeholders and consumers. In terms of application experiences, end-users frequently highlight ease of integration with existing systems, thanks to the customizable nature of fiberglass stacks. Whether upgrading a legacy system or installing a new one, these stacks can be seamlessly incorporated without significant disruptions to ongoing operations. This adaptability reduces the lead time and expedites the transition to more efficient exhaust systems, crucial in industries where time equates to financial cost. In conclusion, fiberglass stacks fulfill essential criteria for modern industrial applications by combining lightweight, durable materials with advanced manufacturing techniques and environmentally sustainable practices. Their adoption reflects a commitment to efficiency, regulatory compliance, and environmental stewardship, crucial values in today’s industrial landscape. As innovations in composite materials continue to evolve, fiberglass stacks will likely remain at the forefront of emission control technology, offering reliable, customizable solutions to industries striving for excellence in operation and environmental responsibility.

A critical component of fiberglass stack success lies in their customization capabilities. Manufacturers can tailor dimensions, shapes, and configurations to cater to specific industrial needs, ensuring a precise match to operational requirements. This adaptability is crucial for facilities operating under unique spatial or production challenges, providing a bespoke solution that enhances operational efficiency and compliance with environmental standards. Trustworthiness is intrinsically linked to the proven track record of fiberglass stacks in various applications worldwide. Companies adopting this technology often report a marked improvement in system reliability and compliance with emission regulations. Testimonials from industry professionals further reinforce this trustworthiness, as they share firsthand accounts of reduced downtime and maintenance costs as a direct result of implementing fiberglass solutions. The environmental impact of using fiberglass stacks cannot be overstated. Unlike metal equivalents that may contribute to excessive resource extraction and energy-intensive manufacturing processes, fiberglass production is relatively energy-efficient. Additionally, fiberglass stacks can be recycled, making them a sustainable choice in the broader narrative of environmentally conscious manufacturing practices. This aligns with the growing corporate trend of adopting greener technologies that resonate with environmentally aware stakeholders and consumers. In terms of application experiences, end-users frequently highlight ease of integration with existing systems, thanks to the customizable nature of fiberglass stacks. Whether upgrading a legacy system or installing a new one, these stacks can be seamlessly incorporated without significant disruptions to ongoing operations. This adaptability reduces the lead time and expedites the transition to more efficient exhaust systems, crucial in industries where time equates to financial cost. In conclusion, fiberglass stacks fulfill essential criteria for modern industrial applications by combining lightweight, durable materials with advanced manufacturing techniques and environmentally sustainable practices. Their adoption reflects a commitment to efficiency, regulatory compliance, and environmental stewardship, crucial values in today’s industrial landscape. As innovations in composite materials continue to evolve, fiberglass stacks will likely remain at the forefront of emission control technology, offering reliable, customizable solutions to industries striving for excellence in operation and environmental responsibility.

Next:

Related Products