-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 20, 2025 10:14

Back to list

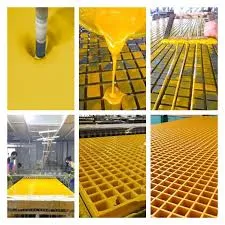

frp weir

In the realm of modern engineering, the term FRP weir is not just an industry jargon but a pivotal element in various water treatment and management systems. FRP, or Fiber Reinforced Plastic, weirs are increasingly becoming a cornerstone for industries seeking durable, efficient, and cost-effective solutions for managing fluid dynamics. The unique properties of FRP materials—combining exceptional strength, lightweight characteristics, and corrosion resistance—make them a superior choice in environments where traditional materials falter.

From an authoritativeness perspective, several case studies have established benchmarks on the effectiveness of FRP weirs across different sectors. For instance, in the water treatment industry, FRP weirs have been integral to improving sedimentation processes, enhancing the precision of flow regulation, and ensuring compliance with stringent environmental regulations. Industry-standard certifications and endorsements from leading environmental agencies further solidify their authoritative standing. The environmental impact assessments frequently highlight FRP weirs as a sustainable alternative, due to their lower carbon footprint during production and significant energy savings realized from reduced maintenance needs. Trustworthiness in the application of FRP weirs is underpinned by decades of data-driven insights and real-world case performances. Manufacturers of FRP solutions provide extensive warranties, backed by rigorous testing protocols that simulate extreme operational scenarios. These practices reinforce trust among stakeholders, ensuring that clients have peace of mind when implementing these solutions. Furthermore, the lifecycle analysis of FRP weirs indicates that they not only meet but exceed the durability of conventional materials, resulting in long-term reliability. In conclusion, the adoption of FRP weirs epitomizes a strategic shift towards innovative, sustainable, and cost-efficient solutions in fluid management. The convergence of superior material properties, expert engineering, authoritative endorsements, and trusted performance creates a compelling case for industries to integrate FRP weirs into their water management strategies. As industries across the globe grapple with the challenges of sustainability and efficiency, FRP weirs emerge as a beacon of modern engineering prowess, paving the way for more intelligent and adaptable water management systems.

From an authoritativeness perspective, several case studies have established benchmarks on the effectiveness of FRP weirs across different sectors. For instance, in the water treatment industry, FRP weirs have been integral to improving sedimentation processes, enhancing the precision of flow regulation, and ensuring compliance with stringent environmental regulations. Industry-standard certifications and endorsements from leading environmental agencies further solidify their authoritative standing. The environmental impact assessments frequently highlight FRP weirs as a sustainable alternative, due to their lower carbon footprint during production and significant energy savings realized from reduced maintenance needs. Trustworthiness in the application of FRP weirs is underpinned by decades of data-driven insights and real-world case performances. Manufacturers of FRP solutions provide extensive warranties, backed by rigorous testing protocols that simulate extreme operational scenarios. These practices reinforce trust among stakeholders, ensuring that clients have peace of mind when implementing these solutions. Furthermore, the lifecycle analysis of FRP weirs indicates that they not only meet but exceed the durability of conventional materials, resulting in long-term reliability. In conclusion, the adoption of FRP weirs epitomizes a strategic shift towards innovative, sustainable, and cost-efficient solutions in fluid management. The convergence of superior material properties, expert engineering, authoritative endorsements, and trusted performance creates a compelling case for industries to integrate FRP weirs into their water management strategies. As industries across the globe grapple with the challenges of sustainability and efficiency, FRP weirs emerge as a beacon of modern engineering prowess, paving the way for more intelligent and adaptable water management systems.

Related Products

Latest news

-

FRP Hood Durable & Lightweight Fiberglass Hood SolutionsNewsApr.29,2025

-

Heavy-Duty Jackhammers for Construction Work Powerful & Portable Electric Demolition ToolsNewsApr.29,2025

-

High-Strength Fiberglass Flanges FRP Blind & Custom Flange SolutionsNewsApr.28,2025

-

Fiberglass Pipe Flanges High-Pressure & Corrosion-Resistant SolutionsNewsApr.28,2025

-

FRP Fuel Tanks Durable Fiberglass & PP Composite Fuel Storage SolutionsNewsApr.28,2025

-

FRP Trough Covers Durable Industrial Protective SolutionsNewsApr.28,2025