-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Future Innovations in Molded Grating Technology

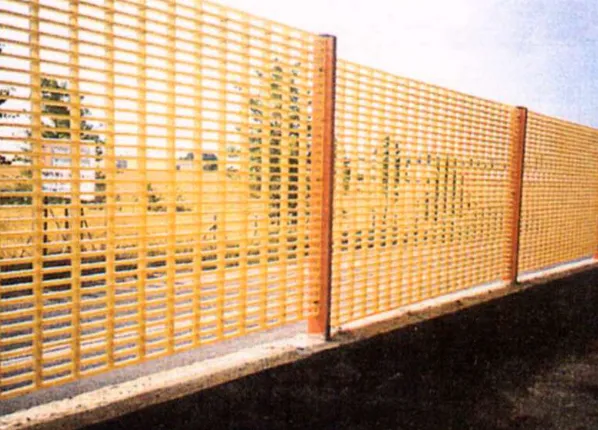

The world of industrial materials is constantly evolving, driven by demands for greater durability, safety, efficiency, and sustainability. Within this landscape, fiberglass reinforced plastic (FRP) products, particularly molded grating, have established themselves as indispensable solutions across diverse sectors – from chemical plants and offshore platforms to walkways and water treatment facilities. Standing at the forefront of this evolution is Hengshui Jrain Frp Co., Ltd.. Located in Hengshui City, China, Jrain FRP has been a dedicated professional manufacturer of composite products since 2008. For over 15 years, the company has actively focused on manufacturing various high-quality FRP items while relentlessly pursuing improvements in product design, manufacturing processes, and market development. This commitment positions Jrain to not only meet current industry needs but also actively shape the future of molded grating technology. As we look ahead, several key areas of innovation promise to further enhance the performance and application scope of these versatile products.

Advancements in Core Molded Grating Design and Performance

The fundamental structure of molded grating is ripe for refinement. Jrain FRP, leveraging its extensive manufacturing experience, is exploring innovations focused on enhancing strength-to-weight ratios even further. Future iterations may incorporate advanced resin formulations offering superior chemical resistance against an even broader spectrum of aggressive substances, extending the lifespan of installations in the harshest environments. Furthermore, research into optimized fiber architectures and potentially integrating nanomaterials could lead to gratings with significantly increased load-bearing capacities without adding bulk or weight. This aligns perfectly with Jrain's existing advantage: Jrain panels are molded in one piece and feature a concave non-slip walking surface. Future designs might enhance this concave profile or introduce novel surface textures using the molding process itself, providing even greater slip resistance under challenging conditions. The inherent benefit remains: The cost effective panels allow for efficient on-site cutting to minimize grating waste and load bearing bars in both directions allow for use without continuous side support. Expect future Jrain molded grating to offer even more versatile standard and custom panel sizes, building upon their current robust specifications:

|

Thickness |

Mesh Pattern |

Panel Sizes (mm) |

|

25.4mm |

38.1 Square |

914.4 x 3048.0 |

|

25.4mm |

25.4x101.6 Rectangular |

914.4 x 3048.0 |

|

38.1mm |

19.1x19.1 Mini-Grid |

1219.2 x 3657.6 |

|

38.1mm |

38.1x152.4 Rectangular |

1219.2 x 3657.6 |

|

38.1mm |

38.1 Square |

914.4 x 3048.0 |

|

50.8mm |

50.8 Square |

1219.2 x 3657.6 |

Enhancing Safety and Functionality in Fiberglass Floor Grating Applications

Fiberglass floor grating is a critical safety component in countless industrial and commercial settings. Future innovations will likely focus intensely on enhancing user safety and functional performance. Beyond improved slip resistance, we anticipate developments in fire retardancy, potentially achieving higher ratings or developing formulations that emit less smoke and toxic fumes. Integration of smart technologies is another frontier. Imagine fiberglass floor grating embedded with subtle sensors to monitor load stress in real-time, detect surface conditions (like ice or excessive moisture), or even incorporate lighting elements for enhanced visibility in low-light areas, all while maintaining the material's inherent non-conductive properties. Jrain's current products already offer significant advantages: Jrain's molded fiberglass grating is significantly lighter in weight than metallic gratings and the high resin content provides excellent corrosion resistance and requires very little maintenance. Future innovations will build upon this reliable foundation, making fiberglass floor grating even safer, smarter, and easier to maintain over its long service life, especially in large-scale installations where consistent performance is paramount.

Developing Next-Generation Insulated FRP Covers for Diverse Needs

The demand for effective thermal management and containment solutions is growing, driving innovation in insulated FRP covers. Jrain FRP is exploring advanced core materials and composite structures to achieve significantly better thermal insulation properties (lower U-values) without drastically increasing weight or sacrificing structural integrity. Future insulated FRP covers may feature multi-layered designs or incorporate vacuum insulation panels (VIPs) within the FRP shell for superior efficiency. Enhanced sealing mechanisms will also be a focus, ensuring minimal heat loss or gain and preventing condensation issues. Durability remains key; expect new resin systems and gel coats specifically formulated to withstand extreme temperature cycling and UV degradation while maintaining the corrosion resistance inherent in FRP. These advancements will expand the application range of insulated FRP covers beyond traditional uses, potentially into more demanding energy infrastructure, advanced manufacturing, and temperature-sensitive process industries, all benefiting from the lightweight and corrosion-resistant nature of FRP.

FAQs About Fiberglass Floor Grating

What are the primary advantages of choosing molded grating over metal alternatives?

The primary advantages include exceptional corrosion resistance, significantly lighter weight (easing handling and installation), inherent non-conductivity (electrical safety), low maintenance requirements, and long-term cost-effectiveness, especially in corrosive environments where metal grating would degrade rapidly.

How does fiberglass floor grating ensure safety in wet or oily environments?

Fiberglass floor grating typically features a molded-in, concave non-slip surface texture. This design provides superior traction underfoot, significantly reducing the risk of slips and falls, even when the surface is wet, oily, or covered in other common industrial substances.

Can insulated FRP covers be customized for specific temperature retention requirements?

Yes, insulated FRP covers can be engineered with different core materials and thicknesses to achieve specific thermal insulation values (R-values/U-values) required for a particular application, whether the goal is to retain heat, maintain cold temperatures, or simply provide condensation control.

What maintenance is typically required for Jrain's molded grating products?

Jrain's molded fiberglass grating requires very little maintenance. Routine cleaning with water and mild detergent is usually sufficient to keep it looking good and performing safely. Its high resin content provides excellent resistance to corrosion, rot, and UV degradation, eliminating the need for painting or other protective coatings.

Are Jrain's FRP products like molded grating and covers suitable for large-scale industrial projects?

Absolutely. Hengshui Jrain Frp Co., Ltd. manufactures molded grating, fiberglass floor grating, and insulated FRP covers in large quantities specifically to meet the demands of major industrial, infrastructure, and commercial projects. Their standardized panel sizes and efficient production processes ensure reliable supply for extensive installations.

The future of molded grating technology is bright, driven by continuous innovation aimed at enhancing performance, safety, sustainability, and functionality. Companies like Hengshui Jrain Frp Co., Ltd., with their deep expertise in FRP manufacturing since 2008 and commitment to ongoing improvement, are pivotal in bringing these advancements to market. From stronger, smarter fiberglass floor grating to highly efficient insulated FRP covers, the evolution focuses on meeting the increasingly complex demands of modern industry. The core benefits of FRP – corrosion resistance, light weight, strength, and low maintenance – remain foundational, but future innovations promise to elevate these products to new levels of performance and application versatility, ensuring their continued role as essential components in safe and efficient operations worldwide. Jrain FRP stands ready to leverage these innovations, providing large-scale solutions built on a legacy of quality and forward-thinking manufacturing.

Latest news

-

Drill Rod Connections Understanding the Basics and Its Global SignificanceNewsNov.24,2025

-

Rectangular Tank Made of Fiberglass Material – Durable, Cost-Effective Liquid Storage SolutionsNewsNov.24,2025

-

Hollow Drill Rods for Efficient Drilling Operations in the Field | Durable, Lightweight & CustomNewsNov.23,2025

-

Powerful yt27 Rock Drill for Tough Mining Surfaces | Durable & PortableNewsNov.23,2025

-

Why the Reversible Drill Bit Is a Versatile Tool for All Your Drilling NeedsNewsNov.22,2025

-

Fiberglass Food Grade Equipment: Key Features, Benefits & Global ImpactNewsNov.22,2025