-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Steps: Simple Solutions for Every Process

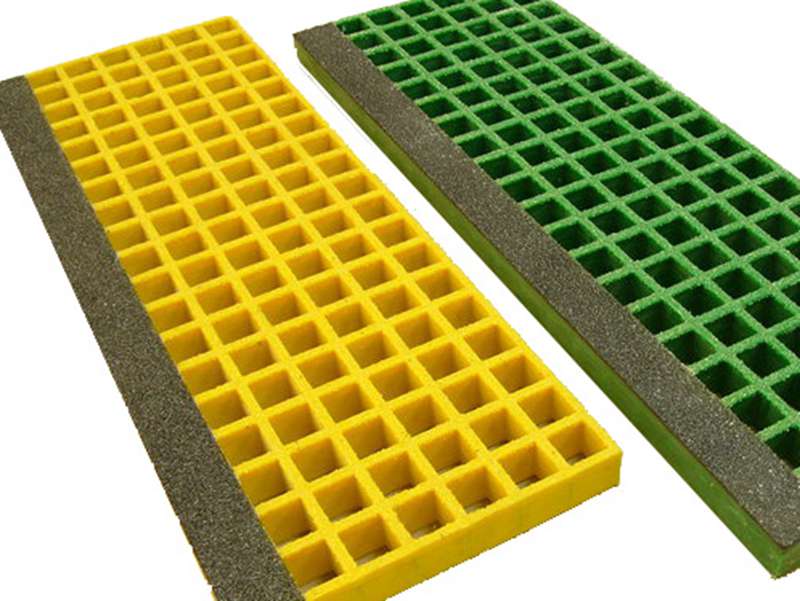

Steps are critical structural and functional components found throughout industrial facilities, municipal infrastructure, petrochemical plants, waterworks, and metallurgy sites. As the backbone of safe access solutions, high-performance Steps must comply with stringent mechanical, chemical, and longevity criteria.

In this article, we provide an in-depth exploration of Steps—from cutting-edge material science and rigorous fabrication process flow, to competitive industry analytics, certification benchmarks, technical parameters, and application scenarios.

Whether you are a specification engineer, a procurement specialist, or an asset owner, you'll find actionable intel including production diagrams, specification and performance tables, technical standards, and real-world cases supported by third-party authoritative data.

Product: Steps

Official Site: https://www.jrain-frp.com/steps.html

According to MarketsandMarkets™, the global demand for high-performance Steps, including advanced FRP (Fiber Reinforced Plastic) and metal variants, is expected to surge by 6.5%–8% CAGR over the next 5 years (2024–2029) within sectors such as infrastructure, refinery, municipal utilities, and heavy industry.

Regulatory drives (OSHA, EN, ISO), and the shift toward corrosion-resistant, energy-saving, and low-maintenance products are major catalysts.

- Petrochemical – 33%

- Municipal Utility (Waterworks, Sewage) – 26%

- Metallurgical Plants – 15%

- Construction Infrastructure – 17%

- Other (Marine, Mining) – 9%

| Parameter | FRP Steps | Stainless Steel Steps | Galvanized Steel Steps |

|---|---|---|---|

| Material Standard | Vinyl Ester/Isophthalic Resin + E-glass, ASTM D256 | SS304, SS316, ASTM A240 | Q235B, Hot Dip Zn, ASTM A153 |

| Load Capacity | 8.0–10.5 kN | 12.0–15.0 kN | 10.0–13.0 kN |

| Corrosion Resistance | Excellent (Salt/Acid/Base) | Excellent (Salt/Acid) | Moderate (Base/Moisture) |

| Service Life | 30–50 years | 20–35 years | 10–20 years |

| Temperature Range | -40°C to +120°C | -60°C to +250°C | -30°C to +80°C |

| Certifications | ISO 9001, ISO 14122-3, EN 14122 | ISO 9001, ANSI A1264 | ISO 1461, ASTM A153 |

| Weight (per step) | 1.2–1.7 kg | 2.8–3.3 kg | 2.4–2.9 kg |

| Surface Finish | Anti-slip Grit, Smooth, Custom Colors | Polished, Matte | Galvanized, Matte |

| Environmental Profile | 100% Recyclable, Non-toxic | Recyclable | Recyclable, Zn Emission |

(CNC) → Surface Pre-treatment → Forming/Casting/Forging → Assembly (Welding/Bonding/Fixings) → Finishing (Anti-slip, Coating) → Final Inspection & Testing

(ISO, ANSI) → Packaging & Delivery

- CNC machining ensures dimensional stability & precision (tolerance ≤0.2mm)

- Anti-slip grit application (DIN 51130) for enhanced safety

- 100% inspection: Load, impact, and chemical resistance testing

| Company | Country | Core Material | Certifications | Customization | Delivery Cycle |

|---|---|---|---|---|---|

| JRain FRP Official Site |

China | FRP, SS316, Galvanized | ISO 9001, EN 14122-3, SGS | Yes (OEM/ODM) | 14–28 days |

| Theseus Systems | Germany | SS304/316 | ISO 9001, TUV | Yes | 16–32 days |

| StepSafe Inc. | USA | FRP, Steel | ASTM, ISO, OSHA | Limited | 20–35 days |

| Kaizen FRP | Japan | FRP, Aluminum | ISO, JIS | Yes | 21–30 days |

Steps can be tailored for unparalleled reliability and operational effectiveness in the following key industries:

- Municipal Waterworks: Corrosion-resistant Steps withstand long-term chemical exposure in chlorination and sewage pumping pits. Average replacement interval reduced by >60% versus steel (source: Water Practice & Tech).

- Petrochemical: FRP and stainless Steps resist acidic and solvent vapors (ISO 14122-3 compliance). Installation time cuts: 35% versus welded steel steps.

- Metallurgy: High thermal stability Steps maintain structural integrity in high-load, high-temperature environments.

- Building Infrastructure: Non-conductive FRP Steps ensure safety in electrical switchgear rooms and railway tunnels.

End-User Feedback (2022–2024):

- Steelmaker, India: "FRP Steps have delivered zero corrosion even under harsh acid mist and provide secure footing for our maintenance crews, reducing safety incidents by 40%."

- Municipal Water Utility, Germany: "Service life and product consistency exceeded all DIN and ISO tests, with annual cost-of-ownership down by 58%."

- Refinery Contractor, MEA: "Lightweight Steps allowed for easy, rapid retrofitting in deep manhole risers (installation labor cut by 1/3)."

- Inquiry ➝ Quotation ➝ Design/Approval ➝ Production ➝ Inspection ➝ Shipping

Warranty: Up to 5 years with extended support.

Certifications: ISO 9001, EN, SGS, Factory QA docs available.

Technical Support: 24/7 hotline, video installation guidance, and on-site engineers (for key accounts).

Third-Party Audits: SGS, BV, or TUV audits accepted.

Project File Warranty: Documented for >10 years for reference and repeat orders.

- MarketsandMarkets™: FRP Market Growth Report (2024 ed.)

- IWA Journals: "Industrial Application of FRP Steps," Water Practice & Technology, 2023

- ASTM International, D256 Standard Test Methods for Impact Resistance

- TUV Rheinland: Certification Overview

- ScienceDirect: Performance Comparison of FRP and Metal Steps

- JRain FRP Steps Product Page

Latest news

-

Steps: Simple Solutions for Every ProcessNewsJul.30,2025

-

Other Products for Versatile Solutions – Quality & InnovationNewsJul.29,2025

-

High-Efficiency Winding Machines for Pipes & Tanks - Precise & Durable SolutionsNewsJul.29,2025

-

Large Size Field Tanks for Efficient Storage SolutionsNewsJul.29,2025

-

Premium Custom Covers for All Purposes - Durable & WeatherproofNewsJul.28,2025

-

Large Size Field Tanks for Industrial & Agricultural Storage SolutionsNewsJul.28,2025