-

africano

africano -

albanés

albanés -

amárico

amárico -

árabe

árabe -

armenio

armenio -

azerbaiyano

azerbaiyano -

vasco

vasco -

bielorruso

bielorruso -

bengalí

bengalí -

bosníaco

bosníaco -

búlgaro

búlgaro -

catalán

catalán -

Cebuano

Cebuano -

China

China -

China (Taiwán)

China (Taiwán) -

corso

corso -

croata

croata -

checo

checo -

danés

danés -

holandés

holandés -

inglés

inglés -

Esperanto

Esperanto -

Estonio

Estonio -

finés

finés -

francés

francés -

frisón

frisón -

galego

galego -

xeorxiano

xeorxiano -

alemán

alemán -

grego

grego -

Gujarati

Gujarati -

crioulo haitiano

crioulo haitiano -

hausa

hausa -

hawaiano

hawaiano -

hebreo

hebreo -

non

non -

Miao

Miao -

húngaro

húngaro -

islandés

islandés -

igbo

igbo -

indonesio

indonesio -

irlandesa

irlandesa -

italiano

italiano -

xaponés

xaponés -

xavanés

xavanés -

Kannada

Kannada -

casco

casco -

Khmer

Khmer -

Ruandés

Ruandés -

coreano

coreano -

kurdo

kurdo -

Kirguises

Kirguises -

TB

TB -

latín

latín -

letón

letón -

lituano

lituano -

luxemburgués

luxemburgués -

macedonio

macedonio -

Malgashi

Malgashi -

malaio

malaio -

Malayalam

Malayalam -

maltés

maltés -

maorí

maorí -

Marathi

Marathi -

mongol

mongol -

Myanmar

Myanmar -

nepalí

nepalí -

noruegués

noruegués -

noruegués

noruegués -

occitano

occitano -

Pashto

Pashto -

persa

persa -

polaco

polaco -

portugués

portugués -

Punjabi

Punjabi -

romanés

romanés -

ruso

ruso -

samoano

samoano -

Gaélico escocés

Gaélico escocés -

serbio

serbio -

inglés

inglés -

Shona

Shona -

Sindhi

Sindhi -

cingalés

cingalés -

eslovaco

eslovaco -

esloveno

esloveno -

somalí

somalí -

español

español -

sundanés

sundanés -

suahili

suahili -

sueco

sueco -

Tagalo

Tagalo -

taxico

taxico -

Tamil

Tamil -

tártaro

tártaro -

Telugu

Telugu -

tailandés

tailandés -

turco

turco -

turcomano

turcomano -

ucraíno

ucraíno -

Urdú

Urdú -

uigur

uigur -

uzbeco

uzbeco -

vietnamita

vietnamita -

galés

galés -

Axuda

Axuda -

yiddish

yiddish -

ioruba

ioruba -

Zulú

Zulú

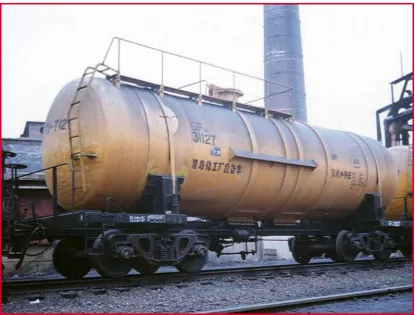

Fiberglass Transport Tank Capacity Options and Specifications

The capacity selection for Fiberglass Transport Tanks represents a critical decision point for industries requiring safe and efficient liquid transportation solutions. These advanced composite tanks offer superior performance characteristics compared to traditional metal alternatives, with capacity options being one of the most important specifications to consider when selecting the appropriate transport solution.

Os tanques de transporte de fibra de vidro inclúen:

|

Features |

Descriptions |

|

Microbiological corrosion resistance |

Resistant to degradation caused by microbial activity, ensuring long-term integrity. |

|

Smooth surface and easy to be cleaned |

Surface finish minimizes residue buildup and simplifies maintenance. |

|

High strength and high-pressure resistance |

Capable of withstanding heavy loads and high internal/external pressures. |

|

Aging resistance |

Engineered to resist environmental factors (e.g., UV, chemicals) that cause deterioration. |

|

Peso lixeiro |

Reduces transportation costs and simplifies handling compared to metal counterparts. |

|

Low thermal conductivity |

Provides natural insulation, reducing heat transfer and energy loss. |

|

Effective constant temperature storage |

Maintains stable internal temperatures for sensitive materials. |

|

Long service life (≥35 years) |

Durable construction ensures reliable performance over decades. |

|

Maintenance-free |

Requires minimal upkeep, lowering operational costs and downtime. |

|

Customizable heating/cooling devices |

Can be equipped with optional systems to meet temperature-controlled transport needs. |

Key Features of GRP Transport Tanks

• GRP Transport Tanks utilize glass-reinforced plastic construction with optional thermoplastic liners for hazardous material containment

• Premium corrosion-resistant resin formulations ensure long-term durability against aggressive chemicals

• Lightweight construction provides significant weight savings compared to steel alternatives

• UV-resistant exterior coatings protect against solar degradation during transport

• Structural reinforcements specifically engineered for road transportation stresses

• Standard capacity options ranging from two thousand to thirty thousand liters

• Custom diameter configurations from one point five to three meters available

• Excellent thermal properties maintain liquid temperatures during transit

Applications of FRP Transport Tanks

• Chemical transportation including hydrochloric acid, sulfuric acid, and sodium hydroxide solutions

• Environmental applications for wastewater and sewage transport systems

• Food-grade liquid transportation including brine solutions and purified water

• Pharmaceutical industry applications requiring ultra-pure containment

• Petroleum and defense sector specialized transport requirements

• Smelting and industrial process liquid transfer applications

• Multiple compartment designs for simultaneous transport of different liquids

Technical Specifications for Fiberglass Transport Tanks

• Manufactured to strict UN and ADR transportation standards

• Dual laminate construction options for hazardous materials

• Pressure ratings up to two point five bar standard (higher available)

• Secondary containment systems for added safety

• Grounding and bonding provisions for flammable liquids

• Advanced venting and pressure management systems

• Custom baffle designs for liquid surge control

• Multiple fitting and connection configurations

• FDA-compliant options for food and beverage applications

• Explosion-proof designs available for volatile substances

Manufacturing Excellence of Fiberglass Transport Tanks

• Proprietary mold technology allows unlimited size configurations

• Stringent raw material quality control procedures

• Computer-controlled production processes

• Advanced filament winding techniques

• Continuous quality monitoring throughout manufacturing

•Rapid project completion without quality compromise

Fiberglass Transport Tank FAQs

-

What maintenance requirements do FRP Transport Tanks have?

FRP Transport Tanksrequire significantly less maintenance than metal tanks, with only periodic visual inspections and routine cleaning needed. The non-corrosive nature eliminates the need for protective coatings or cathodic protection systems required by steel alternatives.-

How does the weight of GRP Transport Tanks compare to steel?

GRP Transport Tankstypically weigh only twenty-five to thirty percent of equivalent steel tanks, providing substantial payload advantages while maintaining superior chemical resistance and durability.-

What certifications do your Fiberglass Transport Tanks carry?

Our Fiberglass Transport Tanksare manufactured to meet UN, ADR, and other international transportation standards, with additional certifications including ASME, FDA, and European pressure equipment directives available for specific applications.-

Can these tanks be customized for special applications?

Yes, we offer complete customization of Fiberglass Transport Tanksincluding special sizes, multiple compartments, unique fitting configurations, and material formulations tailored to specific chemical compatibility requirements.- Why Choose Our Fiberglass Transport Tank Solutions?

Our Fiberglass Transport Tanksrepresent the optimal combination of advanced materials engineering and practical transportation solutions. With unmatched chemical resistance, lightweight durability, and customizable configurations, we provide transport tank solutions that deliver long-term value and reliability across numerous industries. Our commitment to manufacturing excellence ensures every tank meets the highest quality standards while our engineering expertise guarantees optimal performance for your specific application requirements.

Contact Our Transport Tank Specialists Today,For expert assistance in selecting the perfect Fiberglass Transport Tank capacity and configuration for your needs, visit our www.jrain-frp.com or contact our engineering team directly. We'll work with you to develop a transportation solution that meets your exact specifications while ensuring compliance with all relevant safety and regulatory requirements. Let us demonstrate why leading companies worldwide trust our transport tank solutions for their most demanding liquid transportation challenges .

Últimas novas

-

Fiberglass Duct Our Commitment to Quality719NovasAug.22,2025

-

Fiberglass Duct Our Commitment to QualityNovasAug.20,2025

-

FRP Winding Machine with Precision WindingNovasAug.20,2025

-

Fiberglass Walkway Grating with Easy InstallationNovasAug.20,2025

-

Rectangular Fiberglass Tanks for Industrial StorageNovasAug.20,2025

-

FRP Piping System in Industrial Water DistributionNovasAug.20,2025