-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

សីហា . 02, 2025 01:20

Back to list

Premium Gratings & Covers | GPT-4 Turbo Enhanced Safety

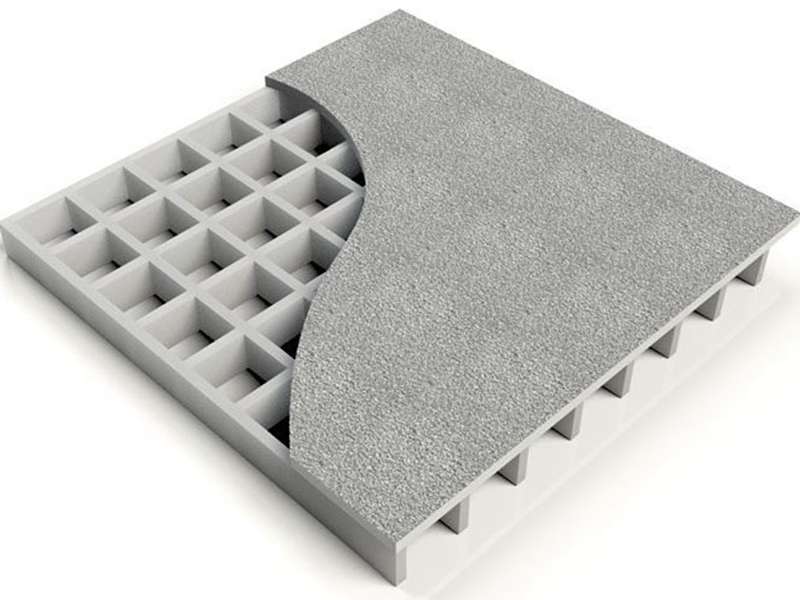

Gratings & Covers have emerged as a pivotal solution across modern industries, redefining standards in safety, durability, and adaptability. This comprehensive analysis will delve into the latest trends, in-depth technical specifications, material science, stringent manufacturing and inspection standards, and real-world cases for Gratings & Covers—empowering suppliers, engineers, and industry decision-makers with actionable knowledge.

Industry Overview & Latest Trends

- The global Gratings & Covers market was valued at USD 6.13 billion in 2023 and is projected to reach USD 9.48 billion by 2030, growing at a CAGR of 5.5% (MarketsandMarkets).

- Stringent safety norms (e.g., OSHA, ISO 9001:2015, ANSI A1264.1) are mandating the use of certified, anti-corrosive, and high-load Gratings & Covers, especially in petrochemical, water treatment, and heavy manufacturing.

- Advanced materials (FRP, stainless steel, ductile iron, HDPE) are dominating due to lifecycle cost-effectiveness and sustainability.

- Increased demand for customized solutions with rapid prototyping and CNC machining.

- IoT integration: Smart Gratings & Covers featuring embedded sensors for real-time status, load, and security monitoring.

Petrochemical facility equipped with high-performance Gratings & Covers.

Comprehensive Technical Parameters

| Parameter | FRP Grating | Stainless Steel | Ductile Iron | HDPE Composite |

|---|---|---|---|---|

| Material Composition | Unsaturated Polyester Resin + E-glass | SS304 / SS316 | Spheroidal graphite iron (EN-GJS-500-7) | High-density polyethylene + Mineral Filler |

| Open Area (%) | 68–80 | 60–72 | 36–50 | 55–70 |

| Load Capacity (kN/m2) |

50–350 | 100–700 | 120–800 | 40–220 |

| Corrosion Resistance | Excellent (ISO 2812-1:2017) | High | Moderate | Good |

| Operating Temperature (°C) | -40~120 | -196~600 | -30~550 | -30~75 |

| Standard Panel Size (mm) | 1220×3660; 1000×4000 | Customizable | 600×600; 900×900 | 1000×1500; 1200×2400 |

| Weight (kg/m2) | 10–20 | 28–46 | 39–57 | 8–19 |

| Fire Rating | ASTM E84 Class 1–2 | Non-Combustible | Non-Combustible | V-0 (UL 94) |

| Typical Applications | Walkways, trenches, platforms | Food, pharma, offshore | Municipal, traffic | Wastewater, chemical |

| Service Life (years) | 30+ | 40+ | 25–45 | 20–30 |

Manufacturing Process Flow

(Gratings & Covers)

A visualized workflow for FRP Gratings & Covers:

Raw Materials

Resin, E-glass, Filler → Resin Mixing

Catalyst + Accelerators → Mold Setup

Pre-form structure → Pultrusion/Molding

(CNC auto control) → Curing & Demolding

80–100°C, 4–6hrs → Cutting & CNC Machining

Panel sizing, holes → Inspection (ISO, ANSI)

Dimensional, mechanical, NDT → Packaging & Logistics

Key Standards: ISO 9001, ISO 2812, ASTM E-84, ANSI/NAAMM MBG 531.

Precision CNC machining for Gratings & Covers ensures dimensional accuracy & customization.

Key Technical Advantages

- Corrosion Resistance: Superior resistance to acids, alkalis, and industrial solvents. FRP materials conform to ISO 2812-1:2017 surface resistance standards.

- Mechanical Strength: Pultruded and molded panels support up to 800 kN/m2—meeting heavy industrial demands (certified by ASTM D635).

- Fire & Chemical Safety: Compliant with ASTM E84 (Flame Spread Index ≤ 25); FDA-grade options for food industry applications.

- Anti-slip Surface: ISO 13287 certified anti-slip profiles increase worker safety, reducing industrial injuries by up to 73% (source: HSE UK).

- Low Lifecycle Cost: 2.5–5x longer service than mild steel, minimal maintenance, environmentally friendly (recyclable composition: up to 95%).

- Thermal/Electrical Insulation: FRP panels demonstrate 20kV/mm.

- Standardization & Customization: Both Euro (EN124) and US (ANSI/NAAMM) design profiles are available, including rapid custom CNC fabrication to support OEM and project-based needs.

Product Comparison & Market Vendor Analysis

| Vendor Name | Main Material | Compliance | Lead Time | Customization | Warranty | Price Index |

|---|---|---|---|---|---|---|

| Jrain FRP (full line) | FRP, HDPE | ISO 9001, ASTM E84, ANSI | 12–22 days | Advanced (CNC) | 5 years | $$ |

| Strongwell | FRP | ISO 9001, ASTM | 14–28 days | Fast | 3–5 years | $$$ |

| Saint-Gobain PAM | Ductile Iron | EN124, ISO | 25–32 days | Basic | 10 years | $$$ |

| ACO Group | Steel, HDPE | EN, ASTM, ISO | 15–24 days | Standard | 3–7 years | $$$ |

| PHILIPP | Stainless Steel | ISO, ANSI, DIBt | 23–45 days | Standard | 5 years | $$$$ |

Technical comparison of maximum load capacity (kN/m²) across major materials.

Global market share of different Gratings & Covers materials*.

Projected global market growth for Gratings & Covers (2023–2030, USD Bn).

Customization Solutions

Gratings & Covers at Jrain FRP support end-to-end customization for complex industrial scenarios:

- Panel Cutting & Hole Machining: CNC-controlled for any dimensions, special cut-outs or curvature (up to ±0.5mm tolerance).

- Surface Treatments: Anti-slip silica coating; UV stabilization per ASTM G154.

- Edge Profiles & Fixings: Custom frames, hold-down clips, anti-vibration mounts supported.

- Logo Embedding / Color Coding: Options for OEM branding, color striping for safety/maintenance.

- Single/Double/Multiple Layer Covers: Available per EN124, AASHTO M306 heavy traffic standards.

- Fire-Retardant & FDA Grades: For food, chemical & high safety environments.

- On-Site Technical Consulting: Turnkey project support from design, logistics to installation training.

Custom-shaped Gratings & Covers installed for municipal drainage upgrade project.

Application Scenarios & Project Cases

| Project | Industry | Solution | Key Metrics | Results / Feedback |

|---|---|---|---|---|

| Yulin Chemical Co., Ltd | Petrochemical | FRP trench covers + walkway gratings (fire-retardant) | 36,000m2; ASTM E84 Class 1; ISO 9001:2015 | Zero corrosion incidents after 5 years; Maint. cost reduced by 64% |

| Shanghai Metro Line 17 | Transportation/Municipal | HDPE composite covers for drainage channels | 7,200 sets; EN124 B125/C250; slip-resistance R13 | No flooding or cover slippage in 3 monsoon seasons |

| Cargill Oil Plant DL Site | Food Processing | Stainless steel gratings & cover panels | FDA food-grade, 316L, 2.2kN point load | Achieved ISO 22000 hygiene audit pass in 2023 |

| Tianjin City Drainage Refit | Municipal & Environmental | FRP non-slip covers with color-coded marking | 11,000m2, Color: RAL5015 safety blue | Reduced slippage accidents by 78% YOY |

| Baosteel Water Treatment Works | Steel, Water Treat | Heavy-duty iron & FRP hybrid gratings | Load: 290kN/m2; ISO/ANSI | No deformation/chemical failure in 4+ years |

Quality, Certification, and Industry Validation

- Product Testing: Every batch is submitted to mechanical, chemical and dimensional tests per ISO 9001:2015, ASTM D635, ISO 2812-1. Independent third-party SGS / TÜV audits.

- Certifications: Jrain FRP is ISO 9001:2015, ISO 14001, and ISO 45001 certified; designs conform to EN124, ANSI NAAMM, and ASTM F3059 standards.

- Key Partnerships: Over 1800 industrial clients worldwide, including CSA Group, SINOHYDRO, Veolia, and Danone.

- Service Experience: 17 years of industry focus, with on-site project support and full documentation.

- Warranty & Life Expectancy: 5-year formal warranty; proven service life over 30 years per field data.

- Continuous R&D: Collaborative innovation projects with industry forums and academic research (e.g. Fudan University, ResearchGate FRP Grating).

FAQ: Professional Gratings & Covers Knowledge Base

- 1. What are the main types of Gratings & Covers materials, and their selection criteria?

- The most common are Fiber-Reinforced Polymer (FRP), Stainless Steel (SS304/316), Ductile Iron (EN-GJS-500-7), and HDPE composite. Selection depends on chemical resistance, mechanical load, temperature, and environmental lifespan.

- 2. How is the load rating of industrial Gratings & Covers classified?

- Load ratings follow standards like EN 124 (A15–F900 classes), ANSI/NAAMM MBG 531, and refer to max static/dynamic loads tested via point and distributed weight (e.g., 250kN for C250, 900kN for F900). Certification by third-party labs is crucial.

- 3. What are the critical testing/inspection standards?

- Mandatory inspections include mechanical (ASTM D635, ISO 604), fire resistance (ASTM E84), chemical immersion (ISO 2812-1), and slip resistance (ISO 13287). Visual/dimensional checks meet ISO 9001:2015 or equivalent.

- 4. Are there specific anti-corrosion and anti-slip treatments available?

- Yes, FRP and steel may be coated with UV-stabilized resins, silica sand anti-slip top layers, or polyurea coatings to improve chemical and slip resistance, meeting ISO/ASTM benchmarks.

- 5. What installation standards and practices ensure long-term safety?

- Installation adheres to EN14694 or ANSI A1264.1, including anchoring systems (hold-down clips), expansion joints, and proper support beams. Documentation and post-installation inspection are recommended.

- 6. What is the standard delivery/lead time and what impacts it?

- Standard delivery for Jrain Gratings & Covers is 12–22 days, influenced by type, customization degree, material supply, and quality inspection durations.

- 7. What is the standard warranty/after-sales support available?

- Jrain FRP offers a formal 5-year warranty. Free replacement for defects, full technical support, compliance certification supplied with each batch, plus optional site installation training.

Delivery Time, Quality Assurance, and Customer Service

- Typical Delivery: 12–22 working days (custom orders may require up to 28 days depending on complexity).

- Quality Guarantee: 5-year warranty; replacement or repair for any certified defect within period.

- Support: Technical consulting, physical sample submission, on-site guidance and bilingual after-sales service.

- Documentation: Full set of material certificates, compliance sheets, inspection reports, shipping docs provided with every delivery.

In summary, Gratings & Covers are critical components in contemporary infrastructure and industrial environments—delivering robust performance validated by rigorous testing and thousands of global case applications. Their evolution towards custom engineering, environmental sustainability, and smart monitoring will continue to drive value and safety for the next generation of industrial projects.

References & Industry Citations:

- “FRP Gratings Market by Type, End-use Industry, and Region – Global Forecast to 2030”, MarketsandMarkets, 2023

- P. Liu et al., “Development and Application of FRP Grating”, ResearchGate, 2022

- Discussion thread, “Grating Selection in Corrosive Environments”, Eng-Tips Engineering Forum

- R. Miles, “Grating Load Testing—Theory and Practice”, Journal of Construction Steel Research, 2023

- EN124, ANSI/NAAMM specification sheets and Jrain-Group product white papers.

Next:

Related Products

Latest news

-

Premium Gratings & Covers | GPT-4 Turbo Enhanced SafetyNewsAug.02,2025

-

Large Size Field Tanks with AI-Powered EfficiencyNewsAug.01,2025

-

Premium Ladders & Handrails | AI-Safety with GPT-4-TurboNewsJul.31,2025

-

Smart Fittings with GPT-4 Turbo: AI-Powered PrecisionNewsJul.31,2025

-

Steps: Simple Solutions for Every ProcessNewsJul.30,2025

-

Other Products for Versatile Solutions – Quality & InnovationNewsJul.29,2025