-

ಆಫ್ರಿಕನ್

ಆಫ್ರಿಕನ್ -

ಅಲ್ಬೇನಿಯನ್

ಅಲ್ಬೇನಿಯನ್ -

ಅಂಹರಿಕ್

ಅಂಹರಿಕ್ -

ಅರೇಬಿಕ್

ಅರೇಬಿಕ್ -

ಅರ್ಮೇನಿಯನ್

ಅರ್ಮೇನಿಯನ್ -

ಅಜೆರ್ಬೈಜಾನಿ

ಅಜೆರ್ಬೈಜಾನಿ -

ಬಾಸ್ಕ್

ಬಾಸ್ಕ್ -

ಬೆಲರೂಸಿಯನ್

ಬೆಲರೂಸಿಯನ್ -

ಬೆಂಗಾಲಿ

ಬೆಂಗಾಲಿ -

ಬೋಸ್ನಿಯನ್

ಬೋಸ್ನಿಯನ್ -

ಬಲ್ಗೇರಿಯನ್

ಬಲ್ಗೇರಿಯನ್ -

ಕೆಟಲಾನ್

ಕೆಟಲಾನ್ -

ಸೆಬುವಾನೋ

ಸೆಬುವಾನೋ -

ಚೀನಾ

ಚೀನಾ -

ಚೀನಾ (ತೈವಾನ್)

ಚೀನಾ (ತೈವಾನ್) -

ಕಾರ್ಸಿಕನ್

ಕಾರ್ಸಿಕನ್ -

ಕ್ರೊಯೇಷಿಯನ್

ಕ್ರೊಯೇಷಿಯನ್ -

ಜೆಕ್

ಜೆಕ್ -

ಡ್ಯಾನಿಶ್

ಡ್ಯಾನಿಶ್ -

ಡಚ್

ಡಚ್ -

ಆಂಗ್ಲ

ಆಂಗ್ಲ -

ಎಸ್ಪೆರಾಂಟೊ

ಎಸ್ಪೆರಾಂಟೊ -

ಎಸ್ಟೋನಿಯನ್

ಎಸ್ಟೋನಿಯನ್ -

ಫಿನ್ನಿಶ್

ಫಿನ್ನಿಶ್ -

ಫ್ರೆಂಚ್

ಫ್ರೆಂಚ್ -

ಫ್ರಿಸಿಯನ್

ಫ್ರಿಸಿಯನ್ -

ಗ್ಯಾಲಿಷಿಯನ್

ಗ್ಯಾಲಿಷಿಯನ್ -

ಜಾರ್ಜಿಯನ್

ಜಾರ್ಜಿಯನ್ -

ಜರ್ಮನ್

ಜರ್ಮನ್ -

ಗ್ರೀಕ್

ಗ್ರೀಕ್ -

ಗುಜರಾತಿ

ಗುಜರಾತಿ -

ಹೈಟಿ ಕ್ರಿಯೋಲ್

ಹೈಟಿ ಕ್ರಿಯೋಲ್ -

ಹೌಸಾ

ಹೌಸಾ -

ಹವಾಯಿಯನ್

ಹವಾಯಿಯನ್ -

ಹೀಬ್ರೂ

ಹೀಬ್ರೂ -

ಇಲ್ಲ

ಇಲ್ಲ -

ಮಿಯಾವೋ

ಮಿಯಾವೋ -

ಹಂಗೇರಿಯನ್

ಹಂಗೇರಿಯನ್ -

ಐಸ್ಲ್ಯಾಂಡಿಕ್

ಐಸ್ಲ್ಯಾಂಡಿಕ್ -

ಇಗ್ಬೊ

ಇಗ್ಬೊ -

ಇಂಡೋನೇಷಿಯನ್

ಇಂಡೋನೇಷಿಯನ್ -

ಐರಿಷ್

ಐರಿಷ್ -

ಇಟಾಲಿಯನ್

ಇಟಾಲಿಯನ್ -

ಜಪಾನೀಸ್

ಜಪಾನೀಸ್ -

ಜಾವಾನೀಸ್

ಜಾವಾನೀಸ್ -

ಕನ್ನಡ

ಕನ್ನಡ -

ಕಝಕ್

ಕಝಕ್ -

ಖಮೇರ್

ಖಮೇರ್ -

ರವಾಂಡನ್

ರವಾಂಡನ್ -

ಕೊರಿಯನ್

ಕೊರಿಯನ್ -

ಕುರ್ದಿಷ್

ಕುರ್ದಿಷ್ -

ಕಿರ್ಗಿಜ್

ಕಿರ್ಗಿಜ್ -

ಟಿಬಿ

ಟಿಬಿ -

ಲ್ಯಾಟಿನ್

ಲ್ಯಾಟಿನ್ -

ಲಟ್ವಿಯನ್

ಲಟ್ವಿಯನ್ -

ಲಿಥುವೇನಿಯನ್

ಲಿಥುವೇನಿಯನ್ -

ಲಕ್ಸೆಂಬರ್ಗ್

ಲಕ್ಸೆಂಬರ್ಗ್ -

ಮೆಸಿಡೋನಿಯನ್

ಮೆಸಿಡೋನಿಯನ್ -

ಮಾಲ್ಗಾಶಿ

ಮಾಲ್ಗಾಶಿ -

ಮಲಯ

ಮಲಯ -

ಮಲಯಾಳಂ

ಮಲಯಾಳಂ -

ಮಾಲ್ಟೀಸ್

ಮಾಲ್ಟೀಸ್ -

ಮಾವೋರಿ

ಮಾವೋರಿ -

ಮರಾಠಿ

ಮರಾಠಿ -

ಮಂಗೋಲಿಯನ್

ಮಂಗೋಲಿಯನ್ -

ಮ್ಯಾನ್ಮಾರ್

ಮ್ಯಾನ್ಮಾರ್ -

ನೇಪಾಳಿ

ನೇಪಾಳಿ -

ನಾರ್ವೇಜಿಯನ್

ನಾರ್ವೇಜಿಯನ್ -

ನಾರ್ವೇಜಿಯನ್

ನಾರ್ವೇಜಿಯನ್ -

ಆಕ್ಸಿಟಾನ್

ಆಕ್ಸಿಟಾನ್ -

ಪಾಷ್ಟೋ

ಪಾಷ್ಟೋ -

ಪರ್ಷಿಯನ್

ಪರ್ಷಿಯನ್ -

ಹೊಳಪು ಕೊಡು

ಹೊಳಪು ಕೊಡು -

ಪೋರ್ಚುಗೀಸ್

ಪೋರ್ಚುಗೀಸ್ -

ಪಂಜಾಬಿ

ಪಂಜಾಬಿ -

ರೊಮೇನಿಯನ್

ರೊಮೇನಿಯನ್ -

ರಷ್ಯನ್

ರಷ್ಯನ್ -

ಸಮೋವನ್

ಸಮೋವನ್ -

ಸ್ಕಾಟಿಷ್ ಗೇಲಿಕ್

ಸ್ಕಾಟಿಷ್ ಗೇಲಿಕ್ -

ಸರ್ಬಿಯನ್

ಸರ್ಬಿಯನ್ -

ಆಂಗ್ಲ

ಆಂಗ್ಲ -

ಶೋನಾ

ಶೋನಾ -

ಸಿಂಧಿ

ಸಿಂಧಿ -

ಸಿಂಹಳೀಯ

ಸಿಂಹಳೀಯ -

ಸ್ಲೋವಾಕ್

ಸ್ಲೋವಾಕ್ -

ಸ್ಲೊವೇನಿಯನ್

ಸ್ಲೊವೇನಿಯನ್ -

ಸೊಮಾಲಿ

ಸೊಮಾಲಿ -

ಸ್ಪ್ಯಾನಿಷ್

ಸ್ಪ್ಯಾನಿಷ್ -

ಸುಂದನೀಸ್

ಸುಂದನೀಸ್ -

ಸ್ವಾಹಿಲಿ

ಸ್ವಾಹಿಲಿ -

ಸ್ವೀಡಿಷ್

ಸ್ವೀಡಿಷ್ -

ಟ್ಯಾಗಲೋಗ್

ಟ್ಯಾಗಲೋಗ್ -

ತಾಜಿಕ್

ತಾಜಿಕ್ -

ತಮಿಳು

ತಮಿಳು -

ಟಾಟರ್

ಟಾಟರ್ -

ತೆಲುಗು

ತೆಲುಗು -

ಥಾಯ್

ಥಾಯ್ -

ಟರ್ಕಿಶ್

ಟರ್ಕಿಶ್ -

ತುರ್ಕಮೆನ್

ತುರ್ಕಮೆನ್ -

ಉಕ್ರೇನಿಯನ್

ಉಕ್ರೇನಿಯನ್ -

ಉರ್ದು

ಉರ್ದು -

ಉಯಿಘರ್

ಉಯಿಘರ್ -

ಉಜ್ಬೆಕ್

ಉಜ್ಬೆಕ್ -

ವಿಯೆಟ್ನಾಮೀಸ್

ವಿಯೆಟ್ನಾಮೀಸ್ -

ವೆಲ್ಷ್

ವೆಲ್ಷ್ -

ಸಹಾಯ

ಸಹಾಯ -

ಯಿಡ್ಡಿಷ್

ಯಿಡ್ಡಿಷ್ -

ಯೊರುಬಾ

ಯೊರುಬಾ -

ಜುಲು

ಜುಲು

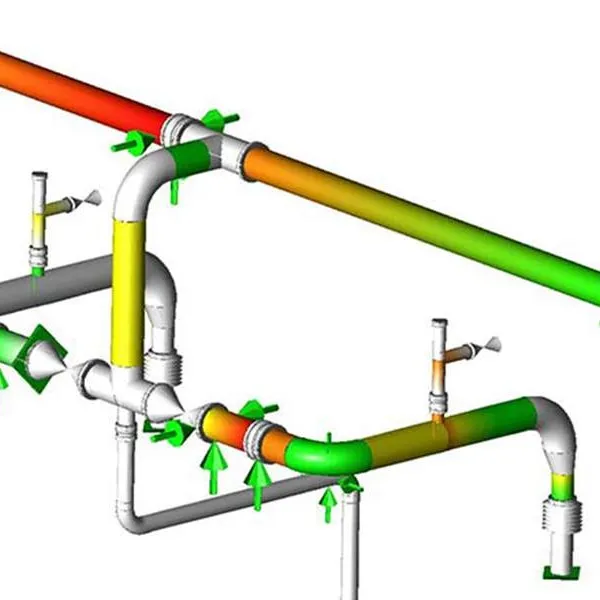

Frp Fittings Installation Guide

The installation of Frp Fittings and Grp Pipe Fittings is a critical aspect of ensuring the durability and functionality of piping systems, particularly in demanding environments such as shipbuilding. Frp Pipes And Fittings offer a range of benefits that make them ideal for various applications, from resistance to corrosion and abrasion to non-conductivity and design flexibility. This guide will provide a comprehensive overview of the installation process for Frp Fittings, highlighting the key steps and considerations to ensure a successful setup.

Understanding the Benefits of Frp Fittings

Before diving into the installation process, it's important to understand the benefits of Frp Fittings. These fittings are known for their long service life and good comprehensive benefits, making them a cost-effective choice for various applications. They also offer low maintenance costs due to their corrosion resistance, abrasion resistance, and pollution resistance, eliminating the need for rust protection and insulation treatment, which can save up to seventy percent on maintenance charges.

-

Installation Process for Frp Fittings

The installation of Frp Fittings involves several key steps. First, ensure that the surface where the fitting will be installed is clean and free of any debris or contaminants. Next, follow the manufacturer's guidelines for preparing the fitting, which may involve cleaning or priming the surfaces. Then, apply the appropriate adhesive or sealant as specified by the manufacturer. Finally, secure the fitting in place, ensuring that it is properly aligned and tightened according to the recommended torque specifications.

-

Maintenance and Care for Frp Fittings

Once installed, Frp Fittings require minimal maintenance due to their inherent properties. However, regular inspections are recommended to check for any signs of wear or damage. This proactive approach can help identify potential issues early, preventing more serious problems down the line. Cleaning should be done with mild soap and water, avoiding harsh chemicals that could damage the fitting.

-

Design Flexibility of Grp Pipe Fittings

One of the key advantages of Grp Pipe Fittings is their design flexibility. These fittings can be designed and manufactured to meet specific pressure, flow rate, and stiffness requirements. This flexibility allows for a tailored solution that fits the unique needs of each project, ensuring optimal performance and efficiency.

-

Abrasion Resistance of Frp Pipes And Fittings

Frp Pipes And Fittings are known for their abrasion resistance, which is particularly important in applications involving slurry or sand. The hardness treatment of these fittings results in significantly less abrasion depth compared to traditional materials like steel pipes coated with tar. This resistance to wear and tear contributes to the long service life of Frp Fittings.

Frp Fittings FAQS

-

What are the main advantages of using Frp Fittings in shipbuilding?

Frp Fittings offer long service life, low maintenance costs, non-conductivity, design flexibility, and abrasion resistance, making them ideal for shipbuilding applications.

-

How do Grp Pipe Fittings compare to traditional metal fittings?

Grp Pipe Fittings provide superior resistance to corrosion, abrasion, and pollution, and they do not require rust protection or insulation treatment, offering significant cost savings and easier maintenance.

-

What is the temperature range for Frp Pipes And Fittings?

Frp Pipes And Fittings are designed to handle liquids at temperatures up to one hundred and thirty degrees Celsius and gases at temperatures up to one hundred and seventy degrees Celsius.

-

Can Frp Fittings be customized to specific project requirements?

Yes, Frp Fittings can be designed and manufactured to meet different pressure, flow rate, and stiffness requirements, providing a tailored solution for each project.

-

What types of thermoplastic liners are available for Frp Pipes And Fittings?

Common thermoplastic liners for Frp Pipes And Fittings include PVC, CPVC, PP, PE, PVDF, etc., offering a superior alternative to costly metal alloys and rubber-lined steel.

Welcome to Hengshui Jrain Frp Co., Ltd. – Your Trusted Partner in Composite Innovation www.jrain-frp.com !

Since 2008, Jrain FRP has been at the forefront of fiberglass reinforced plastic (FRP) excellence, proudly headquartered in Hengshui, China. As a leading professional manufacturer, we specialize in crafting a diverse range of high-quality composite products that blend durability, innovation, and sustainability. Our commitment to continuous improvement drives every aspect of our operations, from refining manufacturing processes to exploring new market frontiers.

At Jrain FRP, our product portfolio spans across industries, offering tailored solutions in FRP fittings, GRP pipe fittings, FRP pipes and fittings, and beyond. Each product is engineered to withstand the toughest environments, from corrosive chemical plants to offshore installations, while adhering to international standards for quality and safety. Our team of experts leverages cutting-edge technology and decades of expertise to deliver custom solutions that meet unique project requirements, ensuring precision and reliability in every component.

We pride ourselves on more than just production; we foster partnerships built on transparency, innovation, and customer-centric service. Whether you need standard components or fully customized composite systems, we collaborate closely with clients worldwide to deliver results that exceed expectations. Our dedication to eco-friendly practices is reflected in our sustainable materials and energy-efficient manufacturing processes, making us a preferred choice for green projects.

Join us in redefining what composite products can achieve. Explore our extensive range, experience our commitment to excellence, and discover why Jrain FRP has been a trusted name in the industry for over a decade.

ಇತ್ತೀಚಿನ ಸುದ್ದಿ

-

fiberglass-duct-our-commitment-to-quality719ಸುದ್ದಿAug.22,2025

-

Fiberglass Duct Our Commitment to Qualityಸುದ್ದಿAug.20,2025

-

FRP Winding Machine with Precision Windingಸುದ್ದಿAug.20,2025

-

Fiberglass Walkway Grating with Easy Installationಸುದ್ದಿAug.20,2025

-

Rectangular Fiberglass Tanks for Industrial Storageಸುದ್ದಿAug.20,2025

-

FRP Piping System in Industrial Water Distributionಸುದ್ದಿAug.20,2025