-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 22, 2025 05:03

Back to list

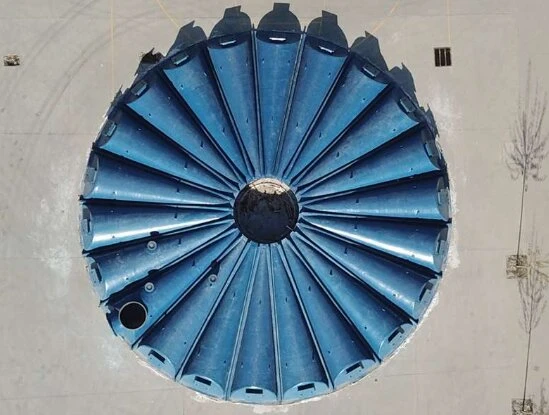

Large Size Field Tanks

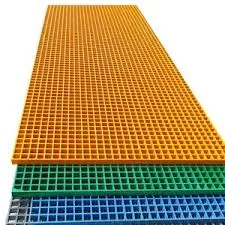

In the construction and industrial sectors, FRP (Fiber Reinforced Plastic) flange blinds represent a paradigm shift in efficiency, durability, and cost-effectiveness. These components are pivotal in a myriad of applications ranging from chemical processing plants to water treatment systems. The appeal of FRP flange blinds lies in their exceptional ability to withstand corrosive environments, their robustness, and minimal maintenance requirements, thereby striking a balance between high performance and cost efficiency—a critical aspect for any industrial setup.

Trustworthiness in utilizing FRP flange blinds is elevated through numerous certifications and compliance with international standards. Manufacturers often subject their products to rigorous testing to ensure they can withstand both the pressures and corrosive nature of various industrial applications. This aligns with global quality assurance processes, providing a layer of trust and dependability for engineers and project managers who rely on these components for critical operations. Aligning with these standards not only boosts the confidence of stakeholders but also demonstrates commitment to safety and reliability. The versatility of FRP flange blinds further extends to their adaptability in different applications. They can be customized to accommodate a wide range of specifications, including varying pressures, temperatures, and chemical exposures. This customization ability is vital as it allows for the tailored integration of flange blinds into existing systems without substantial modifications, thereby saving on potential costs and downtime. Moreover, the ecological aspect of using FRP cannot be overstated. As industries face increasing pressure to adopt sustainable practices, the use of environmentally friendly materials like FRP becomes even more relevant. FRP's extended lifespan reduces the need for frequent replacements, and its production process has a relatively lower environmental impact compared to traditional materials—qualities that are highly valued in sustainable manufacturing practices. In conclusion, the decision to implement FRP flange blinds is supported by a solid foundation of experience, expertise, authoritativeness, and trustworthiness. Through real-world applications, specialized knowledge, adherence to stringent standards, and a focus on sustainability, FRP flange blinds emerge as a smart investment, promising enhanced performance, reduced maintenance, and a sustainable footprint. As industries strive for excellence, the adoption of innovative solutions like FRP remains a testament to the commitment to quality and progress.

Trustworthiness in utilizing FRP flange blinds is elevated through numerous certifications and compliance with international standards. Manufacturers often subject their products to rigorous testing to ensure they can withstand both the pressures and corrosive nature of various industrial applications. This aligns with global quality assurance processes, providing a layer of trust and dependability for engineers and project managers who rely on these components for critical operations. Aligning with these standards not only boosts the confidence of stakeholders but also demonstrates commitment to safety and reliability. The versatility of FRP flange blinds further extends to their adaptability in different applications. They can be customized to accommodate a wide range of specifications, including varying pressures, temperatures, and chemical exposures. This customization ability is vital as it allows for the tailored integration of flange blinds into existing systems without substantial modifications, thereby saving on potential costs and downtime. Moreover, the ecological aspect of using FRP cannot be overstated. As industries face increasing pressure to adopt sustainable practices, the use of environmentally friendly materials like FRP becomes even more relevant. FRP's extended lifespan reduces the need for frequent replacements, and its production process has a relatively lower environmental impact compared to traditional materials—qualities that are highly valued in sustainable manufacturing practices. In conclusion, the decision to implement FRP flange blinds is supported by a solid foundation of experience, expertise, authoritativeness, and trustworthiness. Through real-world applications, specialized knowledge, adherence to stringent standards, and a focus on sustainability, FRP flange blinds emerge as a smart investment, promising enhanced performance, reduced maintenance, and a sustainable footprint. As industries strive for excellence, the adoption of innovative solutions like FRP remains a testament to the commitment to quality and progress.

Related Products

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025