-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

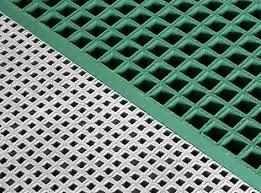

Advanced Fiberglass Winding Technology for Enhanced Performance in Industrial Applications and Innovations

The Importance of Fiberglass Winding Machines in Modern Manufacturing

Fiberglass winding machines play a pivotal role in the manufacturing sector, particularly in the production of composite materials. As industries increasingly seek lightweight, durable, and corrosion-resistant products, fiberglass has emerged as a favored material in various applications, ranging from automotive components to aerospace structures. The efficiency and capability of fiberglass winding machines significantly contribute to this trend.

Understanding Fiberglass Winding

Fiberglass winding is a specialized process that involves the application of fiberglass strands, typically impregnated with resin, onto a rotating mandrel to create composite structures. This method allows for the creation of complex shapes and geometries that are not easily achievable with traditional manufacturing techniques. The winding process can be tailored to meet specific requirements, making it adaptable for various applications, including pipes, tanks, and structural components.

Key Advantages of Fiberglass Winding Machines

1. Precision and Control Modern fiberglass winding machines are equipped with advanced control systems that allow for precise monitoring and adjustment of winding parameters. This capability ensures that the desired thickness, angle, and density of the fiberglass layers are achieved consistently, leading to high-quality end products.

2. Enhanced Production Speed The automation of the winding process significantly increases production speed compared to manual methods. This efficiency not only reduces labor costs but also enables manufacturers to meet growing market demands promptly.

3. Versatility Fiberglass winding machines can be configured for various winding patterns, such as helical, circumferential, and random orientations. This versatility allows manufacturers to cater to diverse applications, meeting specific performance criteria and optimizing material properties.

fiberglass winding machine

4. Reduced Waste With advanced fiber placement technology, fiberglass winding machines minimize material waste. By ensuring that the right amount of fiberglass is applied in the correct location, manufacturers can enhance material usage efficiency and lower production costs.

5. Improved Safety Automated fiberglass winding reduces the need for human intervention in hazardous environments, improving overall workplace safety. This is especially important given the potential health risks associated with handling fiberglass materials and resins.

Applications of Fiberglass Winding Machines

Fiberglass winding machines are employed across a variety of industries. In the automotive sector, they are used to manufacture lightweight components that contribute to fuel efficiency and performance. The aerospace industry benefits from the strength-to-weight ratio of fiberglass composites, making these machines essential for producing critical aircraft components.

In the construction sector, fiberglass winding is utilized to create durable pipes and tanks that resist corrosion and withstand environmental challenges. Furthermore, the wind energy industry relies on fiberglass winding machines for the production of turbine blades, as their lightweight and strong properties enhance energy efficiency and operational performance.

Conclusion

As technology continues to evolve, the importance of fiberglass winding machines in modern manufacturing cannot be overstated. Their ability to produce high-quality, efficient, and customized fiberglass components positions them as invaluable assets across various industries. With ongoing advancements in automation and materials science, the future of fiberglass winding technology looks promising, paving the way for even more innovative applications and solutions. As manufacturers embrace these machines, they will continue to drive efficiency, quality, and sustainability in the production of fiberglass composite materials, ultimately shaping the future of manufacturing.

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025