-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Corrosion Resistance of Fiberglass Ducts in Industrial Applications and Environment

Fiberglass Duct Corrosion Resistance A Comprehensive Insight

Corrosion in industrial settings poses a significant challenge, particularly for systems involving air handling and ductwork. Traditional materials, such as metal ducting, often succumb to rust and degradation in the presence of moisture, chemicals, and other environmental factors. However, fiberglass ductwork has emerged as a robust alternative, offering superior corrosion resistance that is crucial for maintaining the integrity and longevity of air management systems.

Understanding Fiberglass Ducts

Fiberglass ducts are composed of reinforced plastic materials that exhibit remarkable durability and resilience. They are fabricated from a combination of glass fibers and resins, which provide structural strength while also being lightweight and easy to install. One of the most compelling characteristics of fiberglass is its inherent resistance to corrosive elements. Unlike metal ducts, which are prone to oxidation and rusting, fiberglass does not react with chemicals, moisture, or temperature fluctuations, making it an ideal choice for environments where corrosion risk is high.

Corrosion Mechanisms and Their Implications

Corrosion typically occurs when a material undergoes a chemical or electrochemical reaction with its environment. For instance, metallic ducts exposed to moist air or aggressive chemicals can develop rust, which compromises the duct's structural integrity and leads to leaks, reduced efficiency, and increased energy costs. In contrast, fiberglass ducts are immune to such reactions. They can withstand exposure to a wide range of chemicals—acids, bases, and solvents—making them suitable for industries such as food processing, pharmaceuticals, and chemical manufacturing where such materials are prevalent.

Performance in Extreme Conditions

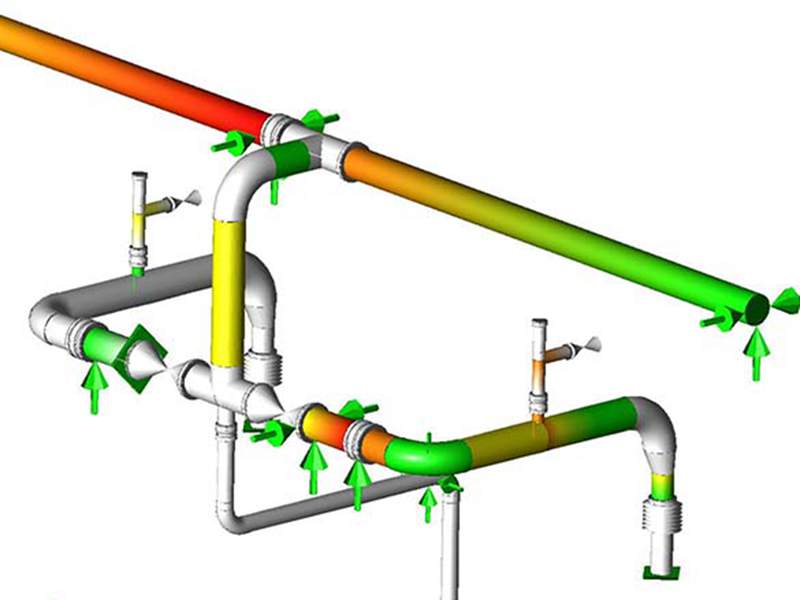

fiberglass duct corrosion resistance

Fiberglass ducts also excel in extreme conditions. Their resistance to both high and low temperatures ensures that they maintain performance in environments where metals might warp or breakdown. Additionally, fiberglass materials do not support microbial growth, a critical factor in maintaining air quality in HVAC systems. This property not only contributes to the longevity of the ductwork but also safeguards the health and comfort of occupants in residential, commercial, and industrial spaces.

Installation and Maintenance Benefits

The installation of fiberglass ducts is also straightforward, saving both time and labor costs. Given their lightweight nature, they are easier to handle and can be cut to size with minimal tools. Once installed, fiberglass ducts require little maintenance. Without the need for regular inspections or treatments to mitigate corrosion, facility managers can focus their resources on other operational aspects rather than worrying about duct integrity.

Environmental Considerations

Another significant advantage of fiberglass ducting is its environmental impact. As industries pivot towards sustainability, choosing materials that are not only long-lasting but also recyclable becomes paramount. Many fiberglass products are manufactured using eco-friendly processes and can be recycled at the end of their service life, aligning with global sustainability goals.

Conclusion

In summary, fiberglass duct corrosion resistance underscores its position as a superior alternative to traditional metal ducting solutions. By providing unmatched resistance to corrosive environments, facilitating easy installation, requiring minimal maintenance, and contributing positively to environmental sustainability, fiberglass ducts stand out as a practical choice in modern industrial applications. As industries continue to evolve and face the challenges of corrosion, the adoption of fiberglass ductwork will likely become a pivotal element in the design and implementation of efficient, reliable air handling systems.

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025