-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

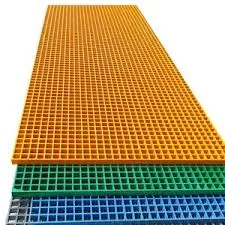

Exploring the Advantages and Applications of Fiberglass Settlers in Industrial Processes and Water Treatment

The Importance of Fiberglass Settlers in Wastewater Treatment

In recent years, the demand for innovative solutions in wastewater treatment has surged, fostering advancements in technology and materials. One of the notable innovations is the use of fiberglass settlers, which have become integral in various industrial and municipal wastewater treatment processes. This article explores the significance, functionality, and benefits of fiberglass settlers in the realm of environmental management.

What is a Fiberglass Settler?

A fiberglass settler is a type of settling tank constructed from fiberglass-reinforced plastic (FRP). This form of construction is particularly advantageous due to fiberglass's lightweight, corrosion-resistant, and durable nature. Unlike traditional materials like concrete or metal, fiberglass settlers offer enhanced resistance to the harsh chemicals commonly found in wastewater. Their design is typically modular, allowing for easy installation and scalability to meet varying wastewater treatment requirements.

How Do Fiberglass Settlers Work?

The operation of a fiberglass settler is fundamentally based on the principle of gravity separation. Wastewater is introduced into the settler, where it slows down, allowing suspended solids to settle at the bottom due to gravity. The settled solids are often referred to as sludge, while the clearer liquid on the surface is termed effluent. The effluent can then be further treated or discharged, while the sludge can be processed separately.

Fiberglass settlers are designed with specific configurations, such as inclined plates, which increase the surface area for solid separation while minimizing the footprint of the settler. Additionally, some settlers incorporate features like baffles to reduce turbulence and enhance settling efficiency.

Advantages of Using Fiberglass Settlers

1. Corrosion Resistance Fiberglass materials withstand corrosion from acidic and alkaline environments, extending the lifespan of the equipment and reducing maintenance costs associated with material degradation.

fiberglass settler

2. Lightweight and Easy Installation The lightweight nature of fiberglass makes it easier and less expensive to transport and install compared to traditional materials. This aspect is particularly beneficial in locations where heavy machinery is challenging to utilize.

3. Customizable Designs Fiberglass settlers can be manufactured in various shapes, sizes, and configurations to fit specific applications. This flexibility allows engineers to optimize designs based on the unique characteristics of the wastewater being treated.

4. Enhanced Performance The effective separation process due to various design advancements leads to higher effluent quality. Cleaner effluent not only meets regulatory standards more easily but also has a lesser environmental impact when discharged.

5. Cost-Effectiveness Although the initial costs of fiberglass settlers may be higher than conventional options, the long-term savings associated with reduced maintenance, longer lifespan, and improved operational efficiency make them an economically sound choice.

Applications in Various Sectors

Fiberglass settlers are utilized across a wide range of sectors, including municipal wastewater treatment plants, industrial manufacturing sites, oil and gas operations, and food processing facilities. In each of these applications, the ability to efficiently separate solids from liquids is crucial in protecting the environment and ensuring compliance with regulations.

Conclusion

As the urgency to improve wastewater management practices continues to grow amid increasing environmental awareness, fiberglass settlers present a compelling solution. Their unique properties and operational efficiency make them a valuable component in the ever-evolving landscape of wastewater treatment technology. By investing in such innovative systems, industries and municipalities can significantly contribute to sustainable practices and environmental stewardship, ensuring cleaner water for future generations.

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025