-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

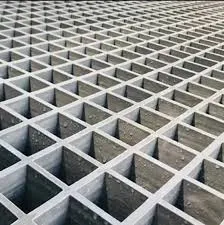

Exploring the Benefits and Applications of FRP Composite Panels in Modern Construction

The Rise of FRP Composite Panels in Modern Construction

In recent years, the construction industry has witnessed a remarkable shift towards the use of advanced materials that enhance performance, sustainability, and efficiency. Among these materials, Fiber Reinforced Polymer (FRP) composite panels have emerged as a game-changer, offering a plethora of advantages over traditional building materials.

FRP composite panels are primarily made from a combination of fibers, such as glass, carbon, or aramid, embedded in a polymer matrix. This unique structure grants them exceptional strength-to-weight ratios, corrosion resistance, and durability, making them ideal candidates for various applications in both residential and commercial construction.

The Rise of FRP Composite Panels in Modern Construction

Furthermore, FRP panels offer outstanding resistance to corrosion and chemical exposure. This property is particularly advantageous in environments where buildings are subjected to harsh conditions, such as coastal areas or industrial zones. Traditional materials often succumb to rust and degradation over time, necessitating costly repairs and maintenance. In contrast, FRP panels maintain their integrity and aesthetic appeal, ensuring longevity and low lifecycle costs.

frp composite panels

In addition to their durability and strength, FRP composite panels also provide excellent thermal and acoustic insulation. This characteristic not only contributes to energy efficiency by reducing heating and cooling demands but also enhances occupant comfort by minimizing noise transmission. As sustainability becomes a central concern in modern construction, the energy-efficient properties of FRP panels align perfectly with green building standards and certifications.

The versatility of FRP composite panels is another compelling reason for their growing popularity. They can be manufactured in various shapes, sizes, and finishes, allowing architects and designers to explore innovative design solutions. Whether used for cladding, roofing, or interior applications, these panels can be tailored to meet specific aesthetic and functional requirements.

Furthermore, the ease of fabrication and customization of FRP panels enables faster construction timelines. Unlike traditional materials that may require extensive processing and curing times, FRP panels can be prefabricated and quickly installed on-site. This acceleration in the construction process can significantly reduce project duration, allowing for quicker occupancy and return on investment.

As the demand for energy-efficient and sustainable building materials continues to rise, FRP composite panels are poised to play a crucial role in the future of construction. With their impressive attributes, including lightweight design, corrosion resistance, thermal insulation, and versatility, FRP panels are not only meeting the needs of today’s builders but are also paving the way for innovative, environmentally friendly building practices.

In conclusion, the increasing adoption of FRP composite panels in construction reflects the industry's broader commitment to sustainability and performance. As technology advances and more research is conducted, we can expect to see even more applications and improvements in FRP materials. This innovative approach to building will not only enhance the functionality and aesthetics of structures but also contribute to a more sustainable built environment for future generations. With their blend of versatility, durability, and efficiency, FRP composite panels represent a significant evolution in construction materials, marking a new era in modern architecture and building design.

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025