-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

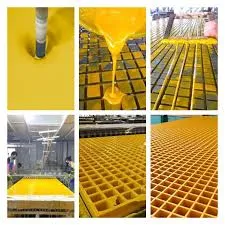

Exploring the Capabilities and Features of FRP Shell for Enhanced Performance and Design Flexibility

Understanding FRP Shells Applications and Advantages

Fiber-reinforced polymer (FRP) shells have gained prominence in various engineering and construction applications due to their unique properties and versatility. These shells, made primarily from composite materials that combine fibers (such as glass, carbon, or aramid) with polymers (resins), exhibit several characteristics that make them suitable for a range of uses, from industrial structures to aesthetic architectural designs.

One of the most significant advantages of FRP shells is their lightweight nature. Compared to traditional materials like steel and concrete, FRP shells are considerably lighter, which can lead to reduced transportation costs and easier handling during construction. This characteristic allows for larger structures to be built with less material, thereby accelerating project timelines and reducing labor costs.

Understanding FRP Shells Applications and Advantages

The versatility of FRP shells is further highlighted in their formability. These shells can be molded into various shapes and sizes, providing architects and engineers with unparalleled creative freedom. Whether it’s creating smooth, flowing lines for aesthetic appeal or building complex geometries for functional purposes, FRP can be shaped to meet the specific requirements of a project. This adaptability also facilitates the integration of various architectural features and elements, allowing for more innovative designs that can enhance both the functionality and visual appeal of a structure.

frp shell

In terms of thermal insulation, FRP shells are also advantageous. They have lower thermal conductivity compared to metals, which can help in energy efficiency and climate control within buildings. This quality makes FRP a popular choice for applications in energy-sensitive industries, contributing to sustainable building practices by reducing the need for extensive heating and cooling systems.

Furthermore, the integration of FRP shells in construction aligns with modern sustainability efforts. Many FRP materials can be produced using recycled fibers and resins, contributing to eco-friendly practices. Moreover, the longevity of FRP products offsets their initial environmental impact, as the reduction in maintenance and replacement needs over time translates to lower overall lifecycle emissions.

Despite these advantages, there are challenges associated with FRP shells that need to be addressed. The initial costs of FRP materials can be higher than traditional options, and the technology for high-performance FRP products continues to evolve. Awareness and training for construction professionals regarding the specific handling and installation techniques required for FRP are vital for its adoption in various industries.

In conclusion, FRP shells represent a significant advancement in material science, offering a combination of lightweight strength, corrosion resistance, aesthetic flexibility, and energy efficiency. As technology continues to develop and the construction industry seeks more sustainable options, the role of FRP shells is likely to expand. Their applications range from civil infrastructure to innovative architectural designs, proving that they are not only functional but also a potential solution for modern engineering challenges. As awareness and knowledge of FRP materials grow, we can anticipate a future where these high-performance shells become a standard choice in both new constructions and rehabilitation projects.

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025