-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

HEAVY DUTY FIBERGLASS GRATING

HEAVY DUTY FIBERGLASS GRATING

Heavy Duty Grating is used to covers areas with heavy traffic. We offer both Pultruded Heavy Duty (HD) Grating and High Load Capacity (HLC) Molded Grating.

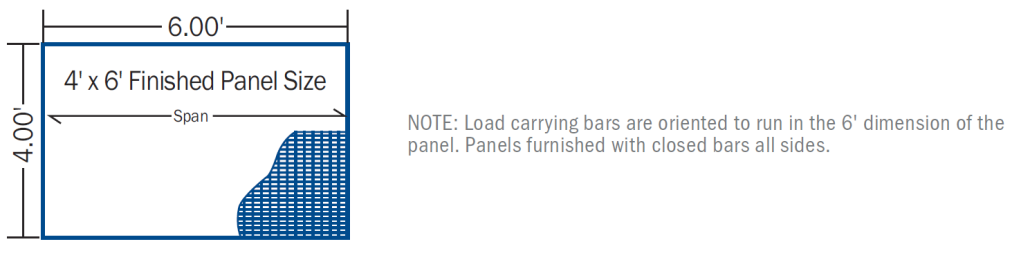

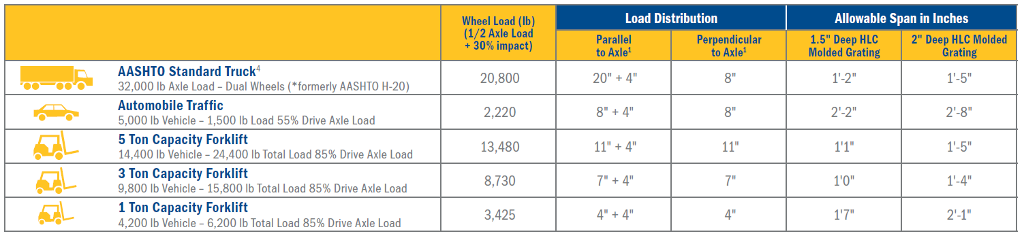

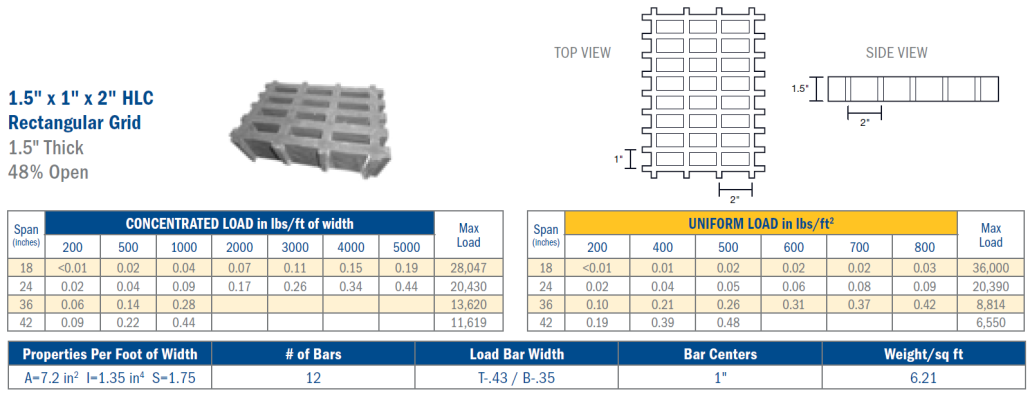

Our High Load Capacity (HLC) molded grating is heavy duty, corrosion-resistant and low-maintenance. It’s engineered to carry heavy traffic liketrucks and forklifts. Our molded HLC FRP Grating is available in 4′ x 6′ panels 1.5″ or 2″ deep in Polyester or Vinyl ester resin systems. HLC grating has many advantages over steel grating for performance and cost effectiveness. With a much higher strength-to-weight ratio, molded HLC fiberglass grating is easy to handle, making for quick installation.

In stock at a distribution center close to you.

Curious about which fiberglass grating specifications are right for your project?

Download our Grating Selection Chart to help you find the right type of grating. To help you with load calculations, we have a handy molded grating load table PDF with information on the load capacities of different grating sizes.

We’re ready to answer any questions – use our Quick Quote Form.

Molded Grating Resin Systems

National Grating Fiberglass Trench and Drain Grates are available in two standard resin systems. Each providing different levels of corrosion protection. Both resin systems meet Class 1 Flame Spread Rating per ASTM E-84 test standards.

Polyester: A premium-grade isophthalic polyester resin system that provides excellent corrosion protection. Standard colors: Dark Gray, Light Gray, Yellow, and Green. Equivalent to Fiberglass Grating Competitor Brand and Strongwell Duragrate PP.

Vinyl ester: A chemically resistant system that provides the highest level of corrosion protection. Standard colors: Yellow, Dark Gray, and Orange. Equivalent to Fiberglass Grating Vinyl Ester and Strongwell Duragrate VE.

Gratings & Covers

Common Sizes and Applications

Common sheet sizes for FRP grating include: 4’x8′, 4’x12′, and 3’x10′. Common thicknesses include: 1″, 1.5″ and 2″

Our molded FRP gratings have applications in many industries, including:

- chemical processing

- food & beverage

- marine

- oil & gas

- power

- manufacturing

- construction

- pharmaceutical

- metals & mining

Strong, Lightweight and Corrosion-Resistant

Molded FRP Grating has the strength of steel, but it won’t corrode like steel can.

Safer Walking Surface for Trench Covers and Fiberglass Walkways

A coarse, gritted epoxy coating enhances traction.

Support and Stability

Molded Fiberglass Grating Panels are equally strong in both directions

Easy Fabrication

FRP Flooring Panels are lightweight, easy to transport, and can be cut and fabricated using standard hand tools.

Extended Life

The coated resin surface increases resistance to chemical corrosion and continuous UV exposure.

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025