-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 19, 2025 05:42

Back to list

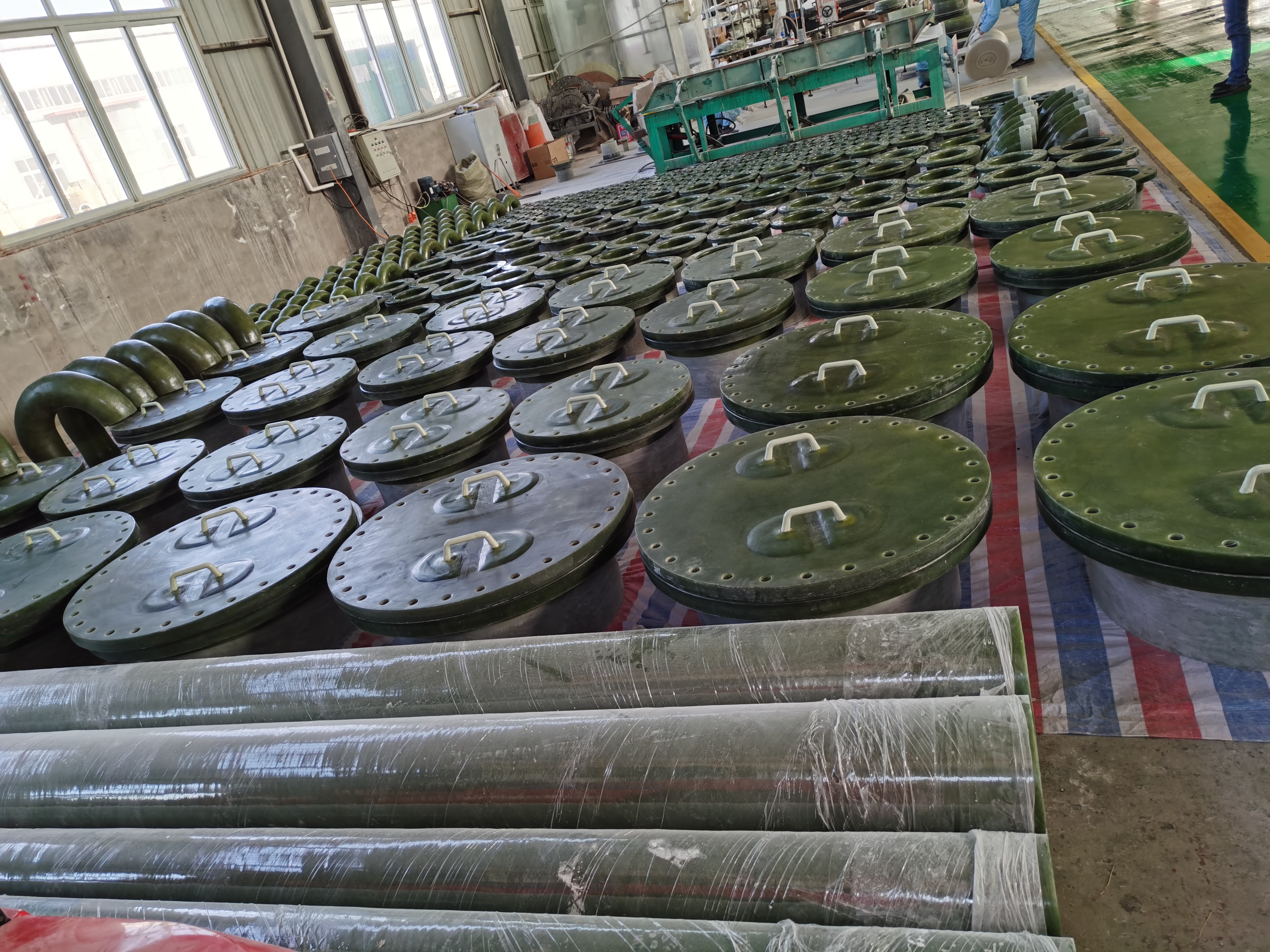

Mandrels and Molds

Fiberglass pipe fittings are essential components in many industrial applications due to their durability, corrosion resistance, and versatility. As industries evolve and the demand for more sustainable materials increases, fiberglass has emerged as a preferred choice for many professionals. Below is an exploration of the benefits, applications, and expert insights into fiberglass pipe fittings.

Experts in the field of industrial materials highlight the competitive advantage offered by fiberglass pipe fittings. Their feedback consistently underscores the material's ability to provide long-term savings and performance reliability. As a testament to their efficacy, numerous industries have transitioned from traditional piping materials to fiberglass, noting significant improvements in operational efficiency and system longevity. The credibility of fiberglass pipe fittings is further reinforced by stringent quality standards and testing. Reputable manufacturers adhere to international specifications, ensuring that each fitting meets safety and performance criteria. Certifications from recognized bodies provide assurance to end-users regarding the reliability and safety of these products. When considering fiberglass pipe fittings, it is crucial to partner with manufacturers and suppliers who possess expertise and a proven track record in the industry. Trustworthy providers not only offer high-quality products but also provide technical support and guidance throughout the selection and installation processes. This collaboration is vital in optimizing the performance and achieving the desired outcomes of any project that incorporates fiberglass pipe fittings. In summary, fiberglass pipe fittings offer a compelling combination of durability, cost-effectiveness, and versatility, making them a superior choice for a wide range of industrial applications. Their role in promoting sustainable practices and reducing operational costs solidifies their status as an invaluable asset in modern infrastructure development. As industries continue to seek innovative solutions, fiberglass pipe fittings are poised to remain at the forefront, ensuring efficient and resilient piping systems for years to come.

Experts in the field of industrial materials highlight the competitive advantage offered by fiberglass pipe fittings. Their feedback consistently underscores the material's ability to provide long-term savings and performance reliability. As a testament to their efficacy, numerous industries have transitioned from traditional piping materials to fiberglass, noting significant improvements in operational efficiency and system longevity. The credibility of fiberglass pipe fittings is further reinforced by stringent quality standards and testing. Reputable manufacturers adhere to international specifications, ensuring that each fitting meets safety and performance criteria. Certifications from recognized bodies provide assurance to end-users regarding the reliability and safety of these products. When considering fiberglass pipe fittings, it is crucial to partner with manufacturers and suppliers who possess expertise and a proven track record in the industry. Trustworthy providers not only offer high-quality products but also provide technical support and guidance throughout the selection and installation processes. This collaboration is vital in optimizing the performance and achieving the desired outcomes of any project that incorporates fiberglass pipe fittings. In summary, fiberglass pipe fittings offer a compelling combination of durability, cost-effectiveness, and versatility, making them a superior choice for a wide range of industrial applications. Their role in promoting sustainable practices and reducing operational costs solidifies their status as an invaluable asset in modern infrastructure development. As industries continue to seek innovative solutions, fiberglass pipe fittings are poised to remain at the forefront, ensuring efficient and resilient piping systems for years to come.

Related Products

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025