-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

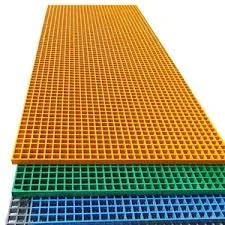

Fire-Resistant Fiberglass Solutions for Enhanced Safety and Durability in Various Applications

The Role of Fire Retardant Fiberglass in Modern Safety Standards

In recent years, the demand for fire safety materials has surged in various industries, driven by increasing safety regulations and a heightened awareness of fire hazards. Among the prominent materials designed to enhance fire resistance, fire retardant fiberglass stands out as a versatile and effective solution.

Fire retardant fiberglass is a composite material that combines the lightweight properties of fiberglass with the enhanced fire resistance provided by various chemical additives. Fiberglass itself is made from fine strands of glass, woven into a fabric or combined with resins to create a solid structure. When treated with fire retardant chemicals, this material can significantly slow down the spread of flames and reduce smoke emissions, making it an ideal choice for applications in construction, automotive, aerospace, and marine industries.

One of the primary benefits of fire retardant fiberglass is its ability to comply with stringent safety standards that are becoming the norm worldwide. For instance, building codes in many regions mandate the use of fire-resistant materials to prevent catastrophic losses in the event of a fire. Fire retardant fiberglass meets these requirements, making it a popular choice for insulation, wall panels, and ceiling tiles in commercial and residential construction. In addition to buildings, this material is also utilized in industrial settings, where machinery and equipment are subject to high temperatures and potential fire hazards.

Moreover, the lightweight nature of fiberglass contributes to its appeal. Conventional fire-resistant materials, such as concrete or steel, can be heavy and cumbersome, often requiring specialized handling and installation. Fire retardant fiberglass, on the other hand, is much lighter, which not only facilitates easier transport and installation but also reduces the overall load on a structure. This feature is particularly beneficial in applications where weight is a critical concern, such as in aerospace and automotive industries.

fire retardant fiberglass

The application of fire retardant fiberglass extends to various products, including electrical enclosures, boat hulls, and automotive components. For example, in the automotive industry, manufacturers are increasingly incorporating fire retardant fiberglass in vehicle designs to enhance safety. In the event of a fire, the material helps protect passengers by delaying flame penetration and minimizing toxic smoke, thus improving survival chances.

Additionally, advancements in technology have led to the development of more effective and environmentally friendly fire retardant chemicals. Manufacturers now have access to a range of options that do not compromise the structural integrity or aesthetics of fiberglass. This innovation aims to address environmental concerns associated with certain chemical fire retardants, transitioning to safer alternatives without sacrificing performance.

Despite its many advantages, it is critical to remember that fire retardant fiberglass is not entirely fireproof. While it can delay fire spread and reduce flames and smoke, it is not a substitute for active fire protection systems, such as sprinklers or fire alarms. Therefore, it should be used as part of a comprehensive fire safety strategy that includes prevention, detection, and suppression systems.

In conclusion, fire retardant fiberglass represents a significant advancement in fire safety materials. Its lightweight, versatile nature combined with effective fire resistance properties makes it an increasingly critical component in various sectors. As industries continue to prioritize safety and adhere to rigorous regulations, the role of fire retardant fiberglass is likely to expand, paving the way for safer buildings, vehicles, and environments. Through ongoing research and innovation, this material will undoubtedly contribute to protecting lives and property from the devastating effects of fire.

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025