-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 09, 2025 12:02

Back to list

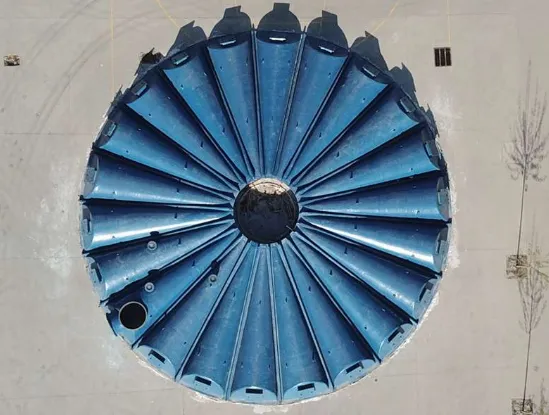

frp customized product

In an era where innovation meets individualistic demands, the FRP (Fiber Reinforced Polymer) customized product sector has emerged as a cornerstone of contemporary industrial solutions. The convergence of cutting-edge materials and customized design opens up a universe of possibilities, challenging traditional manufacturing boundaries and setting new benchmarks for quality and performance. For businesses and individuals seeking to leverage the potential of FRP customized products, understanding their nuances is paramount.

Authoritativeness in the FRP customized product domain is established through continuous research, innovation, and collaboration with industry stakeholders. Leading manufacturers work with academic institutions and participate in global forums to stay abreast of the latest technological advancements and regulatory changes. This commitment to excellence ensures that their products are certified to meet international standards, reassuring clients of their performance and safety credentials. Trustworthiness, a critical pillar in the relationship between suppliers and consumers of FRP products, is built on a foundation of quality assurance and transparency. Manufacturers offer warranties and post-sale support, fostering confidence in their products. Case studies and testimonials from satisfied customers serve as testaments to the reliability and effectiveness of FRP solutions, further solidifying trust in these advanced materials. In conclusion, the FRP customized product industry stands at the intersection of innovation and practical application, offering solutions that are not only custom-tailored but also remarkably effective. By leveraging experience, expertise, authoritativeness, and trustworthiness, stakeholders can navigate this dynamic landscape to unlock new efficiencies and achieve unparalleled performance. As FRP technology evolves, its potential to revolutionize industries continues to expand, promising a future where the only limits are those of imagination.

Authoritativeness in the FRP customized product domain is established through continuous research, innovation, and collaboration with industry stakeholders. Leading manufacturers work with academic institutions and participate in global forums to stay abreast of the latest technological advancements and regulatory changes. This commitment to excellence ensures that their products are certified to meet international standards, reassuring clients of their performance and safety credentials. Trustworthiness, a critical pillar in the relationship between suppliers and consumers of FRP products, is built on a foundation of quality assurance and transparency. Manufacturers offer warranties and post-sale support, fostering confidence in their products. Case studies and testimonials from satisfied customers serve as testaments to the reliability and effectiveness of FRP solutions, further solidifying trust in these advanced materials. In conclusion, the FRP customized product industry stands at the intersection of innovation and practical application, offering solutions that are not only custom-tailored but also remarkably effective. By leveraging experience, expertise, authoritativeness, and trustworthiness, stakeholders can navigate this dynamic landscape to unlock new efficiencies and achieve unparalleled performance. As FRP technology evolves, its potential to revolutionize industries continues to expand, promising a future where the only limits are those of imagination.

Next:

Related Products

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025