Mar . 05, 2025 00:45

Back to list

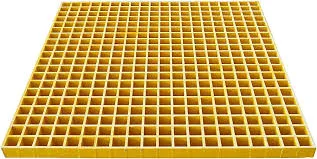

frp flange

The world of piping and infrastructure solutions is evolving rapidly, and one of the notable advances is the increasing use of FRP flanges. Fabricated from Fiber Reinforced Plastics, these flanges are becoming pivotal in applications that demand resilience against corrosive environments, high durability, and economic feasibility. By integrating FRP flanges into your project, you engage with a cutting-edge technology that leverages the benefits of contemporary material science.

From an expertise standpoint, understanding the fabrication process of FRP flanges is essential for appreciating their superiority. These flanges are typically manufactured using advanced molding techniques such as filament winding, resin transfer molding, and vacuum infusion. Each process is designed to optimize the alignment and impregnation of reinforcing fibers within the polymer matrix, resulting in a composite material with enviable strength-to-weight ratios. Additionally, customization options are plentiful, allowing tailor-made solutions that ideally suit specific industrial requirements. Trustworthiness and reliability are non-negotiable in engineering materials, and FRP flanges deliver on both fronts. Proven through rigorous industry testing standards, these flanges meet and often exceed ASTM and ISO benchmarks for performance and safety. By adopting FRP technology, industries not only adhere to stringent regulatory requirements but also position themselves as forward-thinking entities committed to sustainable and innovative solutions. Furthermore, the environmental benefits of using FRP flanges should not be underestimated. Their long lifecycle significantly curtails the frequency of replacements, contributing to a decrease in resource consumption and waste generation. Additionally, advancements in recycling techniques for composite materials are continually reducing the environmental footprint of FRP flanges, making them an increasingly attractive option for eco-conscious organizations. In conclusion, FRP flanges represent a sophisticated blend of modern engineering, material innovation, and pragmatic design. Their application spans a multitude of industries, driven by the unmistakable advantages they offer in terms of durability, cost-effectiveness, and environmental sustainability. As industries continue to evolve and prioritize efficiency and sustainability, the role of FRP flanges becomes ever more critical. Embracing these components not only fosters an innovative edge but also anchors your enterprise as a leader in an era of transformative industrial advancements.

From an expertise standpoint, understanding the fabrication process of FRP flanges is essential for appreciating their superiority. These flanges are typically manufactured using advanced molding techniques such as filament winding, resin transfer molding, and vacuum infusion. Each process is designed to optimize the alignment and impregnation of reinforcing fibers within the polymer matrix, resulting in a composite material with enviable strength-to-weight ratios. Additionally, customization options are plentiful, allowing tailor-made solutions that ideally suit specific industrial requirements. Trustworthiness and reliability are non-negotiable in engineering materials, and FRP flanges deliver on both fronts. Proven through rigorous industry testing standards, these flanges meet and often exceed ASTM and ISO benchmarks for performance and safety. By adopting FRP technology, industries not only adhere to stringent regulatory requirements but also position themselves as forward-thinking entities committed to sustainable and innovative solutions. Furthermore, the environmental benefits of using FRP flanges should not be underestimated. Their long lifecycle significantly curtails the frequency of replacements, contributing to a decrease in resource consumption and waste generation. Additionally, advancements in recycling techniques for composite materials are continually reducing the environmental footprint of FRP flanges, making them an increasingly attractive option for eco-conscious organizations. In conclusion, FRP flanges represent a sophisticated blend of modern engineering, material innovation, and pragmatic design. Their application spans a multitude of industries, driven by the unmistakable advantages they offer in terms of durability, cost-effectiveness, and environmental sustainability. As industries continue to evolve and prioritize efficiency and sustainability, the role of FRP flanges becomes ever more critical. Embracing these components not only fosters an innovative edge but also anchors your enterprise as a leader in an era of transformative industrial advancements.

Next:

Related Products

Latest news

-

Oblate Tanks: Space-Saving, Durable Liquid Storage SolutionsNewsAug.27,2025

-

High-Performance Piping System Solutions for Industry & Commercial UseNewsAug.26,2025

-

Precision Fittings: Durable & Reliable Industrial & Plumbing SolutionsNewsAug.25,2025

-

Practical Steps: Unlock Success with Our Proven GuidesNewsAug.24,2025

-

Transport Tanks: Safe, Durable & Efficient Liquid HaulingNewsAug.23,2025

-

High-Quality Piping Systems for Efficient Flow & DurabilityNewsAug.22,2025