Mar . 04, 2025 08:39

Back to list

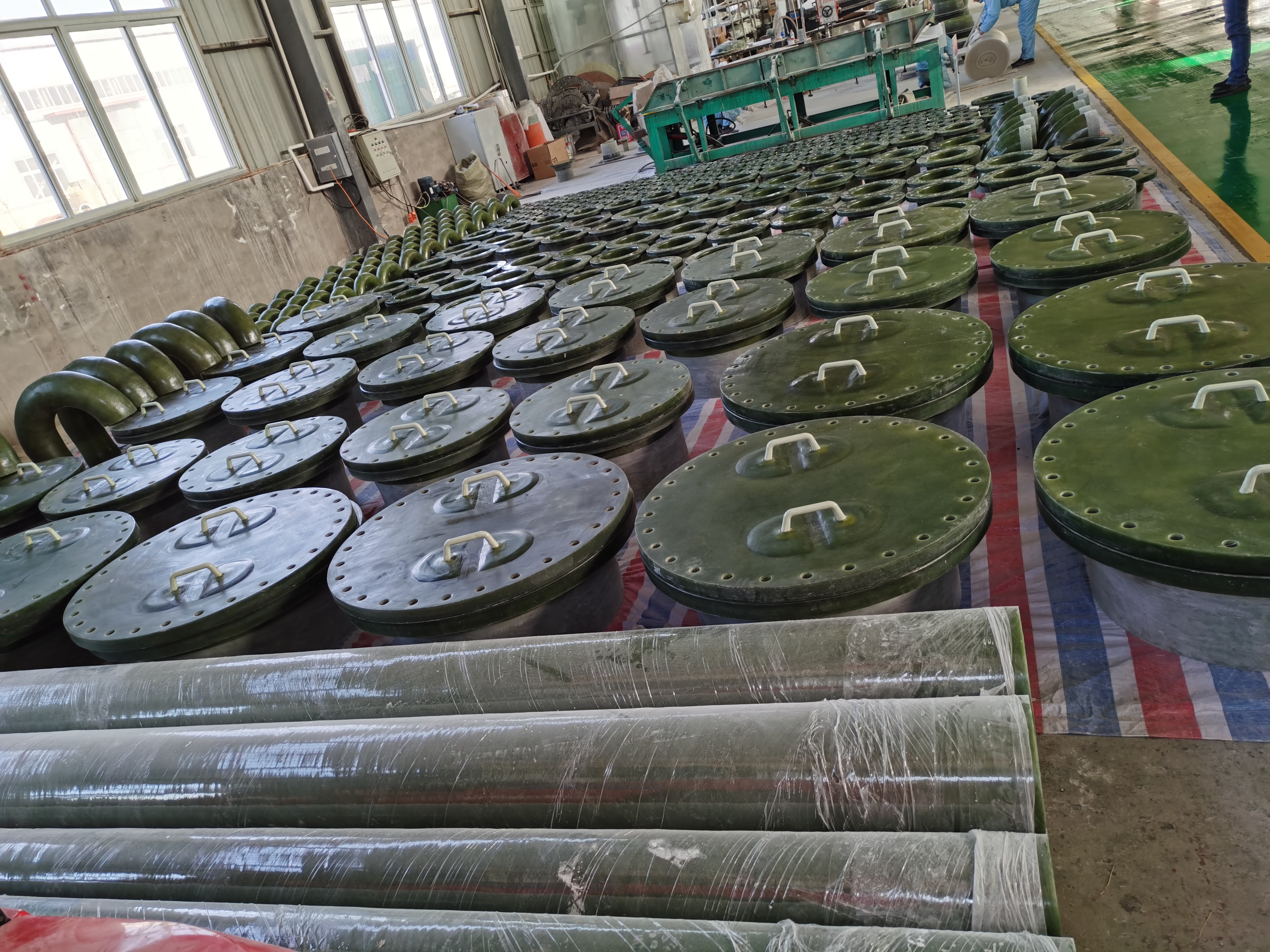

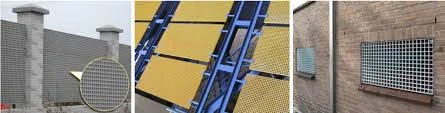

frp insulation tank

In the ever-evolving world of industrial storage solutions, the FRP (Fiber Reinforced Plastic) insulation tank stands out as a feat of modern engineering. Renowned for its durability, cost-effectiveness, and adaptability, this sophisticated tank system has become indispensable in industries ranging from chemical processing to wastewater treatment. Drawing upon a wealth of industry experience and technical expertise, let’s delve into what makes FRP insulation tanks a game-changer.

Safety is another domain where FRP insulation tanks excel. Industries handling volatile storage materials require storage solutions that minimize risk. FRP tanks, being non-conductive and non-reactive, inherently reduce the risk of explosion or contamination, promoting safer working environments. Moreover, these tanks are commonly manufactured in compliance with industry standards such as ASTM and ASME, underscoring their reliability and assuring stakeholders of their performance under critical conditions. The environmental credentials of FRP insulation tanks should not be overlooked. As companies worldwide strive to reduce their environmental footprints, opting for sustainable storage solutions becomes paramount. FRP tanks, due to their long lifespan and minimal maintenance requirements, contribute less waste and require fewer resources over their lifetime compared to traditional tanks. Furthermore, advancements in resin technology have led to the development of eco-friendly composites, further bolstering the sustainability of these tank systems. Undoubtedly, the credibility of FRP insulation tanks is underscored by their widespread industry acceptance and the robust regulatory standards they adhere to. Companies adopting these tanks gain not only operational efficiencies but also enhance their reputation as forward-thinking and responsible market players. The trustworthiness associated with FRP tanks is cemented by the numerous real-world successes and testimonials from leading industries worldwide, making them a first-choice recommendation for new projects and retrofits alike. In summary, FRP insulation tanks represent a culmination of cutting-edge material science, practical engineering, and environmental conscious design. With significant advantages in durability, efficiency, and safety, these tanks are a testament to how modern industrial solutions can meet the demands of the present while preparing for a future trajectory defined by sustainability and technological advancement. As industries continue to seek out the most reliable and efficient solutions, the FRP insulation tank remains a peerless choice, driven by a foundation of expertise and trusted legacy.

Safety is another domain where FRP insulation tanks excel. Industries handling volatile storage materials require storage solutions that minimize risk. FRP tanks, being non-conductive and non-reactive, inherently reduce the risk of explosion or contamination, promoting safer working environments. Moreover, these tanks are commonly manufactured in compliance with industry standards such as ASTM and ASME, underscoring their reliability and assuring stakeholders of their performance under critical conditions. The environmental credentials of FRP insulation tanks should not be overlooked. As companies worldwide strive to reduce their environmental footprints, opting for sustainable storage solutions becomes paramount. FRP tanks, due to their long lifespan and minimal maintenance requirements, contribute less waste and require fewer resources over their lifetime compared to traditional tanks. Furthermore, advancements in resin technology have led to the development of eco-friendly composites, further bolstering the sustainability of these tank systems. Undoubtedly, the credibility of FRP insulation tanks is underscored by their widespread industry acceptance and the robust regulatory standards they adhere to. Companies adopting these tanks gain not only operational efficiencies but also enhance their reputation as forward-thinking and responsible market players. The trustworthiness associated with FRP tanks is cemented by the numerous real-world successes and testimonials from leading industries worldwide, making them a first-choice recommendation for new projects and retrofits alike. In summary, FRP insulation tanks represent a culmination of cutting-edge material science, practical engineering, and environmental conscious design. With significant advantages in durability, efficiency, and safety, these tanks are a testament to how modern industrial solutions can meet the demands of the present while preparing for a future trajectory defined by sustainability and technological advancement. As industries continue to seek out the most reliable and efficient solutions, the FRP insulation tank remains a peerless choice, driven by a foundation of expertise and trusted legacy.

Next:

Related Products

Latest news

-

Oblate Tanks: Space-Saving, Durable Liquid Storage SolutionsNewsAug.27,2025

-

High-Performance Piping System Solutions for Industry & Commercial UseNewsAug.26,2025

-

Precision Fittings: Durable & Reliable Industrial & Plumbing SolutionsNewsAug.25,2025

-

Practical Steps: Unlock Success with Our Proven GuidesNewsAug.24,2025

-

Transport Tanks: Safe, Durable & Efficient Liquid HaulingNewsAug.23,2025

-

High-Quality Piping Systems for Efficient Flow & DurabilityNewsAug.22,2025