-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring New Methods for Efficient FRP Laundering Techniques and Best Practices

Understanding FRP Launder An Innovative Solution for Wastewater Treatment

Fiber Reinforced Plastic (FRP) technology has revolutionized various industries with its remarkable properties of strength, durability, and resistance to corrosion. Among the myriad of applications for FRP, one significant use is in the design and construction of launders for wastewater treatment processes. This article explores the benefits of FRP launders, their structure, applications, and their growing significance in environmental management.

What is an FRP Launder?

A launder is an integral component of a wastewater treatment system, primarily designed for the efficient collection and transportation of treated water. The primary function of a launder is to ensure that the effluent flows smoothly from one treatment stage to another, mitigating any sedimentation and ensuring that the water quality meets environmental standards before being discharged.

FRP launders are made from a composite material consisting of a polymer matrix reinforced with fibers, commonly glass or carbon. This results in a lightweight yet remarkably strong material that can withstand harsh environmental conditions.

Advantages of FRP Launders

1. Corrosion Resistance One of the primary advantages of FRP is its resistance to corrosion. Traditional materials such as steel and concrete are often susceptible to degradation when exposed to corrosive environments present in wastewater treatment plants. FRP launders can withstand various chemicals and pH levels, thus extending their lifespan and reducing maintenance costs.

2. Lightweight Construction The lightweight nature of FRP means that pumps and infrastructure require less support and can be more easily installed. This significantly reduces installation costs and allows for more flexible design options.

3. Reduced Maintenance Due to their durability and corrosion resistance, FRP launders require significantly less maintenance compared to traditional materials. This translates into lower operational costs and increased efficiency in plant management.

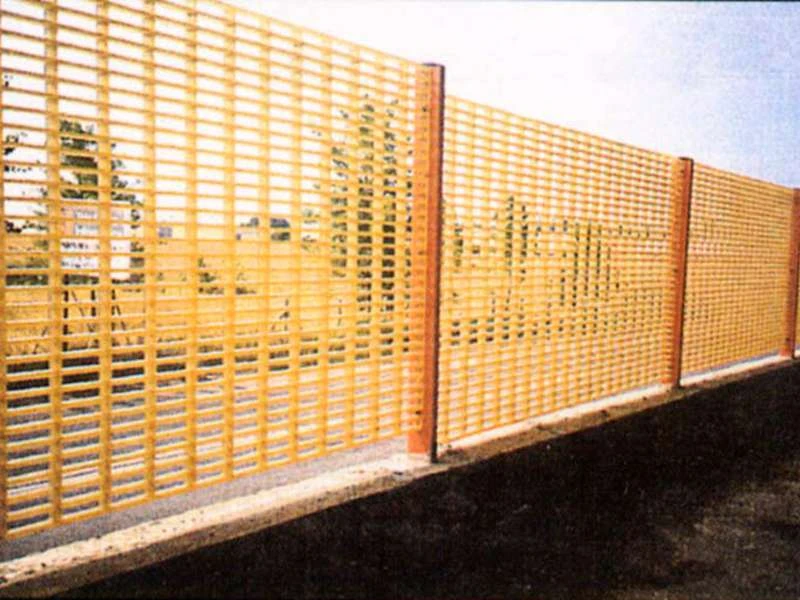

frp launder

4. Customizable Design FRP can be molded into various shapes and sizes, allowing for customized design solutions tailored to specific treatment processes. This flexibility enables engineers to create systems that maximize efficiency and enhance water treatment outcomes.

5. Environmental Impact The use of FRP technology supports sustainability initiatives. By improving the durability and efficiency of wastewater treatment processes, FRP launders contribute to better water quality management, ultimately reducing the adverse effects on local ecosystems.

Applications of FRP Launders

FRP launders are versatile and find applications across various sectors in wastewater treatment. They are commonly used in municipal water treatment facilities, industrial wastewater treatment plants, and even in stormwater management systems. In municipal wastewater treatment, FRP launders can be integrated into secondary treatment processes such as sedimentation tanks and clarifiers to ensure that the flow of effluent is both effective and efficient.

Additionally, in industries where chemical exposure is prevalent, such as the pharmaceutical and food production sectors, FRP launders are ideal due to their inherent resistance to chemicals and hygiene factors.

Conclusion

As water scarcity and environmental regulations become increasingly pressing issues, the demand for efficient and sustainable wastewater treatment technologies continues to grow. FRP launders represent a significant advancement in this field, offering solutions that address the challenges faced by traditional materials. Their unique properties enhance the efficiency of wastewater management systems, contribute to lower operational costs, and facilitate environmentally-friendly practices.

In summary, the adoption of FRP launders in wastewater treatment processes not only improves the overall performance of treatment facilities but also emphasizes the crucial role of innovative materials in achieving sustainable water management solutions for the future.

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025