-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Mar . 05, 2025 07:33

Back to list

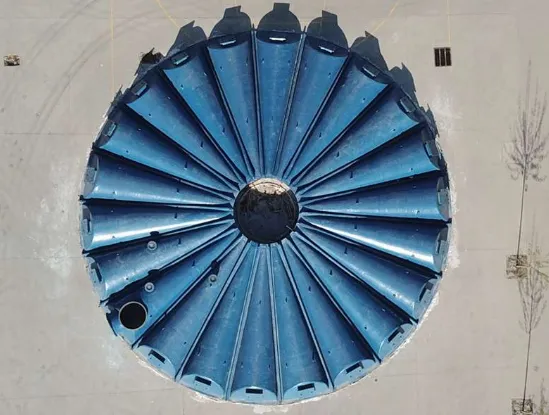

Large Size Field Tanks

In the ever-evolving landscape of maritime technology, the use of fiber-reinforced plastic (FRP) pipes and fittings is making significant waves in shipbuilding. This advancement is transforming the industry by offering innovative solutions that marry durability with efficiency, addressing the modern demands of ship construction and operation.

Moreover, the installation process of FRP pipes and fittings embodies experience and skill, requiring specialized knowledge and precision. Shipbuilders and engineers who work with FRP materials underline the importance of understanding the mechanical properties and proper joining techniques to ensure optimal performance and safety. Their profound expertise ensures that the handling of FRP components is executed flawlessly, reinforcing the reliability of the vessels. In terms of authoritativeness, numerous case studies and industry reports validate the efficacy of FRP materials in shipbuilding. Leading maritime companies and research institutions consistently endorse FRP technologies through extensive testing and real-world applications. Their findings highlight the material's performance under extreme conditions, establishing FRP as a trusted standard within the shipbuilding community. The trustworthiness of FRP pipes and fittings is further bolstered by a legacy of proven results. Vessels equipped with FRP components have logged countless sea miles, consistently demonstrating their durability and dependability. Maintenance records reflect fewer incidents of wear and tear compared to traditional materials, assuring stakeholders of the material’s efficiency and reliability. Ultimately, FRP pipes and fittings represent a pivotal chapter in shipbuilding’s ongoing narrative. Their unmatched properties resonate with modern shipbuilding objectives of sustainability, cost efficiency, and high performance. As shipbuilders continue to embrace innovative materials like FRP, the maritime industry inches closer to a future where excellence and responsibility go hand in hand. Investing in FRP is not just a nod to contemporary demands but a strategic move towards a future-proof fleet.

Moreover, the installation process of FRP pipes and fittings embodies experience and skill, requiring specialized knowledge and precision. Shipbuilders and engineers who work with FRP materials underline the importance of understanding the mechanical properties and proper joining techniques to ensure optimal performance and safety. Their profound expertise ensures that the handling of FRP components is executed flawlessly, reinforcing the reliability of the vessels. In terms of authoritativeness, numerous case studies and industry reports validate the efficacy of FRP materials in shipbuilding. Leading maritime companies and research institutions consistently endorse FRP technologies through extensive testing and real-world applications. Their findings highlight the material's performance under extreme conditions, establishing FRP as a trusted standard within the shipbuilding community. The trustworthiness of FRP pipes and fittings is further bolstered by a legacy of proven results. Vessels equipped with FRP components have logged countless sea miles, consistently demonstrating their durability and dependability. Maintenance records reflect fewer incidents of wear and tear compared to traditional materials, assuring stakeholders of the material’s efficiency and reliability. Ultimately, FRP pipes and fittings represent a pivotal chapter in shipbuilding’s ongoing narrative. Their unmatched properties resonate with modern shipbuilding objectives of sustainability, cost efficiency, and high performance. As shipbuilders continue to embrace innovative materials like FRP, the maritime industry inches closer to a future where excellence and responsibility go hand in hand. Investing in FRP is not just a nod to contemporary demands but a strategic move towards a future-proof fleet.

Related Products

Latest news

-

Fiberglass 90 Degree Elbow for Custom Tanks & High Pressure Pipes Durable and Corrosion ResistantNewsJun.24,2025

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025