-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 09, 2025 11:41

Back to list

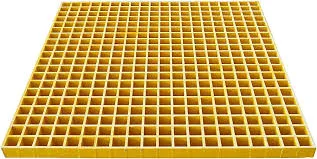

frp scrubber

In the realm of industrial waste management, the significance of air pollution control has never been more paramount. One pivotal solution in this domain is the FRP (Fiberglass Reinforced Plastic) scrubber. These scrubbers stand out not only for their robust performance but also for their lasting durability, making them a preferred choice for many industries facing corrosive environmental challenges.

Despite the inherent complexity in designing and implementing such systems, the user experience with FRP scrubbers has been streamlined through continuous innovation. Manufacturers now offer comprehensive support, helping customers optimize the installation process and providing thorough training to operational staff. This support ensures that industries can leverage the full potential of FRP scrubbers, thus maintaining operational efficiency while adhering to environmental protection mandates. Moreover, the implementation of FRP scrubbers is aligned with the broader movement towards sustainable industrial practices. By adopting such advanced technologies, companies are not only meeting regulatory demands but also demonstrating corporate responsibility and environmental stewardship. This alignment with global sustainability goals enhances their reputation and opens up opportunities for growth in environmentally-conscious markets. In summary, FRP scrubbers epitomize a synergy of engineering excellence, authoritative reliability, and trustworthy operation—factors that drive their increasing adoption across various industries. Their unparalleled durability and efficiency continue to position them as a cornerstone technology in air pollution abatement strategies worldwide. As industrial demands evolve, the role of FRP scrubbers will undoubtedly expand, fueled by ongoing innovations and a steadfast commitment to environmental sustainability.

Despite the inherent complexity in designing and implementing such systems, the user experience with FRP scrubbers has been streamlined through continuous innovation. Manufacturers now offer comprehensive support, helping customers optimize the installation process and providing thorough training to operational staff. This support ensures that industries can leverage the full potential of FRP scrubbers, thus maintaining operational efficiency while adhering to environmental protection mandates. Moreover, the implementation of FRP scrubbers is aligned with the broader movement towards sustainable industrial practices. By adopting such advanced technologies, companies are not only meeting regulatory demands but also demonstrating corporate responsibility and environmental stewardship. This alignment with global sustainability goals enhances their reputation and opens up opportunities for growth in environmentally-conscious markets. In summary, FRP scrubbers epitomize a synergy of engineering excellence, authoritative reliability, and trustworthy operation—factors that drive their increasing adoption across various industries. Their unparalleled durability and efficiency continue to position them as a cornerstone technology in air pollution abatement strategies worldwide. As industrial demands evolve, the role of FRP scrubbers will undoubtedly expand, fueled by ongoing innovations and a steadfast commitment to environmental sustainability.

Next:

Related Products

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025