-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 13, 2025 09:55

Back to list

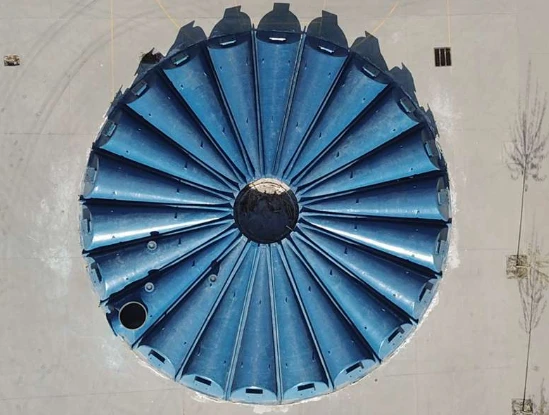

Mandrels and Molds

Fiber Reinforced Plastic (FRP) ducts are revolutionizing the industrial and commercial sectors with their unparalleled benefits and innovative applications. Integrating the latest manufacturing techniques and materials, these ducts are an exemplary choice for a wide range of applications due to their unique properties and advantages.

Safety is paramount in any industrial setting, and FRP ducts excel in this regard due to their non-conductive properties, which mitigate the risk of electrical hazards. Additionally, the materials used in FRP duct construction are often fire-retardant, further enhancing their safety profile. These characteristics not only protect the workplace but also ensure compliance with rigorous safety standards and regulations, providing peace of mind to operators and stakeholders. From an expert perspective, the nuanced engineering behind FRP ducts highlights their superiority. By leveraging advanced composite materials and cutting-edge manufacturing processes, producers can offer ducts with precise dimensions, improved surface finish, and enhanced mechanical properties. This attention to detail and commitment to quality ensures that each FRP duct meets or exceeds industry standards, reinforcing its position as a leading choice for demanding applications. Trustworthiness in product performance is a critical factor for clients investing in infrastructure improvements. Over decades of proven efficacy, FRP ducts have established a reputation for reliability and resilience. Testimonials and case studies from reputable corporations underscore their effectiveness, presenting a compelling narrative that supports their claimed benefits. When choosing an FRP duct system, clients are not only buying a product but investing in a proven technology backed by a wealth of expertise and a track record of success. In summary, the innovative advantages of FRP ducts—ranging from their corrosion resistance, lightweight properties, and energy efficiency, to their safety standards and engineering excellence—offer a compelling value proposition for businesses looking to enhance their operations. The investment in FRP duct systems translates to long-term savings, improved safety, and a robust solution capable of meeting the challenges of modern industrial environments. As industries continue to demand efficiency and innovation, FRP ducts are poised to become an integral component in infrastructure advancement.

Safety is paramount in any industrial setting, and FRP ducts excel in this regard due to their non-conductive properties, which mitigate the risk of electrical hazards. Additionally, the materials used in FRP duct construction are often fire-retardant, further enhancing their safety profile. These characteristics not only protect the workplace but also ensure compliance with rigorous safety standards and regulations, providing peace of mind to operators and stakeholders. From an expert perspective, the nuanced engineering behind FRP ducts highlights their superiority. By leveraging advanced composite materials and cutting-edge manufacturing processes, producers can offer ducts with precise dimensions, improved surface finish, and enhanced mechanical properties. This attention to detail and commitment to quality ensures that each FRP duct meets or exceeds industry standards, reinforcing its position as a leading choice for demanding applications. Trustworthiness in product performance is a critical factor for clients investing in infrastructure improvements. Over decades of proven efficacy, FRP ducts have established a reputation for reliability and resilience. Testimonials and case studies from reputable corporations underscore their effectiveness, presenting a compelling narrative that supports their claimed benefits. When choosing an FRP duct system, clients are not only buying a product but investing in a proven technology backed by a wealth of expertise and a track record of success. In summary, the innovative advantages of FRP ducts—ranging from their corrosion resistance, lightweight properties, and energy efficiency, to their safety standards and engineering excellence—offer a compelling value proposition for businesses looking to enhance their operations. The investment in FRP duct systems translates to long-term savings, improved safety, and a robust solution capable of meeting the challenges of modern industrial environments. As industries continue to demand efficiency and innovation, FRP ducts are poised to become an integral component in infrastructure advancement.

Next:

Related Products

Latest news

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025

-

High-Quality Fiberglass Weir Custom FRP Weir & Fiberglass Tanks ManufacturerNewsJul.07,2025

-

CPVC FRP Pipe A Reliable Choice for Industrial Applications High Strength & Corrosion ResistanceNewsJul.07,2025

-

Fiberglass Scrubber for Effective Cleaning and Stain Removal – Superior Performance in Various ApplicationsNewsJul.06,2025