-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

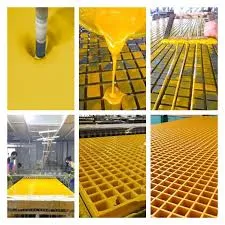

FRP Grating Lightweight & Corrosion-Resistant Fiberglass Floor Grating

- Introduction to FRP Grating and Its Core Advantages

- Technical Specifications and Performance Metrics

- Comparing Leading Manufacturers in the Industry

- Customization Options for Diverse Applications

- Real-World Use Cases Across Industries

- Installation and Maintenance Best Practices

- Why FRP Grating Outperforms Traditional Materials

(frp grating)

Introduction to FRP Grating and Its Core Advantages

Fiberglass Reinforced Plastic (FRP) grating has emerged as a versatile solution for industrial and commercial flooring needs. Unlike traditional steel or aluminum, FRP grating combines corrosion resistance, high strength-to-weight ratios, and longevity. Industries such as chemical processing, marine, and wastewater treatment increasingly favor fiberglass floor grating due to its non-conductive properties and minimal maintenance requirements. For instance, studies show FRP products exhibit less than 0.5% degradation after 20 years in corrosive environments, outperforming steel by over 300% in lifespan.

Technical Specifications and Performance Metrics

FRP grating is engineered to meet rigorous standards, including ASTM E84 for fire resistance and ISO 14125 for load-bearing capacity. Key technical advantages include:

- Load capacity: Up to 1,500 lbs per square foot (PSF) for heavy-duty applications.

- Thermal stability: Performs between -40°F and 180°F without warping.

- Slip resistance: Meets OSHA requirements with a coefficient of friction (COF) ≥0.8.

These metrics make strongwell grating a preferred choice for industries prioritizing safety and durability.

Comparing Leading Manufacturers in the Industry

| Manufacturer | Load Capacity (PSF) | Corrosion Resistance Rating | Weight (lbs/sq ft) | Price Range ($/sq ft) |

|---|---|---|---|---|

| Strongwell | 1,500 | Class A | 3.2 | 25-40 |

| Fibergrate | 1,200 | Class B | 3.5 | 22-35 |

| Bedford | 1,000 | Class B | 4.0 | 20-30 |

Customization Options for Diverse Applications

FRP grating can be tailored to specific project requirements. Customization parameters include:

- Mesh size: Ranging from 1"x1" to 4"x4" for varying load and drainage needs.

- Surface texture: Grit-coated or smooth finishes for slip resistance.

- Color coding: UV-stable pigments for hazard identification or aesthetic alignment.

For example, a petrochemical facility recently deployed yellow-colored frp grating

with 2"x2" mesh to enhance safety in high-traffic zones.

Real-World Use Cases Across Industries

Case studies highlight FRP's adaptability:

- Chemical Plants: Replaced steel grating in a sulfuric acid storage area, reducing replacement costs by 60% over 5 years.

- Offshore Platforms: Installed 10,000 sq ft of fiberglass floor grating with a 30-year anti-corrosion warranty.

- Food Processing: Utilized antimicrobial FRP panels to meet FDA hygiene standards.

Installation and Maintenance Best Practices

Proper installation ensures optimal performance. Key steps include:

- Surface preparation: Clean substrates to prevent debris-induced stress.

- Fastening: Use corrosion-resistant clamps or adhesives compatible with FRP.

- Inspection: Conduct bi-annual checks for debris buildup or surface wear.

Maintenance costs average $0.10/sq ft annually, compared to $0.50/sq ft for painted steel.

Why FRP Grating Outperforms Traditional Materials

In direct comparisons, strongwell grating demonstrates a 40% lower total cost of ownership versus steel over 25 years. Its non-conductive nature eliminates grounding risks, while UV-stabilized formulations prevent fading. As industries prioritize sustainability, FRP’s recyclability and energy-efficient production further solidify its position as the future of industrial flooring solutions.

(frp grating)

FAQS on frp grating

Q: What is FRP grating and its primary benefits?

Q: What is FRP grating and its primary benefits?

A: FRP grating is a fiberglass-reinforced plastic composite material used for structural platforms. It offers corrosion resistance, lightweight strength, and non-conductive properties, making it ideal for harsh environments.

Q: How does fiberglass floor grating compare to traditional materials?

Q: How does fiberglass floor grating compare to traditional materials?

A: Unlike steel or concrete, fiberglass floor grating resists rust, chemicals, and moisture. It is lighter, easier to install, and requires minimal maintenance over time.

Q: What industries commonly use Strongwell grating?

Q: What industries commonly use Strongwell grating?

A: Strongwell grating is widely used in oil and gas, water treatment, and chemical plants. Its durability and corrosion resistance suit demanding industrial and marine applications.

Q: Can FRP grating support heavy loads safely?

Q: Can FRP grating support heavy loads safely?

A: Yes, FRP grating is engineered for high load-bearing capacity. Custom designs from brands like Strongwell ensure compliance with safety standards for pedestrian and vehicular traffic.

Q: How to install fiberglass floor grating correctly?

Q: How to install fiberglass floor grating correctly?

A: Ensure proper alignment and secure edges with corrosion-resistant fasteners. Follow manufacturer guidelines for spacing and support structures to maximize longevity and performance.

Latest news

-

Other Products: Explore Our Diverse RangeNewsAug.07,2025

-

High-Efficiency Fans, Dampers & Demisters | Custom SolutionsNewsAug.06,2025

-

Precision Mandrels and Molds - Engineered SolutionsNewsAug.04,2025

-

Dual Laminate Products | Superior Corrosion ResistanceNewsAug.03,2025

-

Large Size Field Tanks with AI-Powered EfficiencyNewsAug.01,2025

-

Steps: Simple Solutions for Every ProcessNewsJul.30,2025