-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Practical Steps: Unlock Success with Our Proven Guides

Optimizing Industrial Access: A Deep Dive into High-Performance Steps Solutions

In today's complex industrial landscapes, the demand for robust, safe, and durable access solutions is paramount. Traditional materials often succumb to the ravages of harsh environments, leading to costly maintenance, premature replacement, and significant safety risks. This challenge has driven the innovation in advanced composite materials, particularly Fiber Reinforced Polymer (FRP), which offers a transformative alternative. This article provides a comprehensive overview of modern industrial Steps, focusing on their advanced manufacturing processes, superior technical specifications, diverse application scenarios, and compelling economic advantages for B2B decision-makers and engineering professionals.

From the corrosive atmospheres of chemical processing plants to the demanding conditions of offshore oil rigs, the need for reliable pedestrian access cannot be overstated. FRP steps deliver exceptional performance where metallic alternatives fail, providing unmatched corrosion resistance, a high strength-to-weight ratio, non-conductive properties, and minimal maintenance requirements. Our exploration will detail the intricate process flow, analyze prevailing industry trends, present critical technical data, compare vendor offerings, highlight customization capabilities, and share real-world application successes, thereby building a foundational understanding of their integral role in enhancing operational efficiency and safety.

Process Flow: Precision Engineering of FRP Steps

The production of high-performance industrial Steps is a testament to advanced composite manufacturing, primarily leveraging the pultrusion process for structural components like stair treads, and sometimes compression molding for specialized forms. This meticulous approach ensures that each product exhibits optimal mechanical properties, dimensional stability, and resistance to environmental degradation. Key materials include premium-grade thermosetting resins—such as Isophthalic Polyester for general industrial use, Vinyl Ester for aggressive chemical environments, and Phenolic for superior fire resistance—combined with E-glass fibers for reinforcement.

Manufacturing Stages: From Raw Material to Finished Product

- 1. Raw Material Procurement & Formulation: This initial stage involves the precise selection and mixing of liquid resin, fiberglass rovings and mats, catalysts, pigments, UV inhibitors, and flame retardants. The resin system is meticulously formulated to impart specific properties, such as enhanced chemical resistance or fire retardancy, crucial for the intended application. Strict quality control protocols are applied to all incoming materials to ensure consistency.

- 2. Resin Impregnation: Fiberglass reinforcements are continuously pulled through a specialized resin bath. This ensures complete saturation of the fibers with the resin mixture, guaranteeing homogenous material distribution and optimal bonding. Automated systems precisely control the resin uptake.

- 3. Pre-forming and Shaping: The resin-saturated fibers are then guided through a series of pre-forming tools. These tools meticulously compress and shape the material into the desired profile, such as the I-beams or channels that form industrial stair treads. This step removes air voids and ensures structural integrity.

- 4. Pultrusion and Curing: The formed profile is then continuously pulled through a heated die. Within this die, the thermal energy initiates the polymerization process, curing the resin from a liquid to a rigid solid composite. The precise control of temperature and pull speed is vital for achieving a complete cure and a uniform, dense material cross-section. Integrated anti-slip grit surfaces are often applied in this stage for enhanced durability.

- 5. Cutting and Post-Processing: Upon exiting the die, the fully cured profile is automatically cut to exact specifications. Further post-processing, such as drilling, routing, or the application of additional protective coatings, may be performed to meet specific project requirements.

Rigorous Testing Standards and Extended Service Life

Each batch of FRP steps undergoes stringent quality assurance and testing to comply with international industry standards, ensuring peak performance and reliability. Key certifications and testing include:

- ISO 9001: Certification for Quality Management Systems, ensuring consistent manufacturing and product quality.

- ASTM E-84: Standard Test Method for Surface Burning Characteristics of Building Materials, critical for fire safety ratings (Flame Spread and Smoke Development).

- ASTM D-638 / D-790: Tests for Tensile Properties and Flexural Properties, respectively, confirming the material's load-bearing capacity and structural resilience.

- ASTM D-695: Standard Test Method for Compressive Properties of Rigid Plastics, assessing resistance to crushing forces.

- ANSI A14.7: American National Standard for Ladders – Safety Requirements, specifically for fiber-reinforced plastic ladders and ladder components.

This exhaustive process and adherence to global standards translate into an impressive service life, often exceeding 20 years, even in the most aggressive industrial environments, without significant degradation or maintenance.

Target Industries and Core Advantages in Application

FRP steps are strategically engineered for industries where environmental stressors compromise traditional materials. Their inherent properties provide distinct advantages:

- Petrochemical & Chemical Processing: Superior corrosion resistance to a wide array of acids, alkalis, and solvents significantly reduces component failure and the high costs associated with replacement and downtime.

- Metallurgy & Mining: Non-conductive properties ensure safety in areas with electrical hazards, while resistance to abrasive and corrosive elements common in these heavy industries ensures longevity.

- Water Supply & Drainage / Wastewater Treatment: Unaffected by continuous exposure to moisture, chlorine, hydrogen sulfide, and other aggressive chemicals, providing decades of reliable service where steel rapidly deteriorates.

- Marine & Offshore: Excellent resistance to saltwater, UV radiation, and high humidity, coupled with a high strength-to-weight ratio, makes them ideal for gangways, platforms, and access ways on rigs and ships.

- Food & Beverage: Hygienic, easy-to-clean surfaces and resistance to wash-down chemicals make them suitable for stringent sanitation environments.

These applications highlight the benefits of FRP steps, including energy saving through reduced material transport and installation efforts, unparalleled corrosion resistance that eliminates frequent repainting and replacement, and inherent non-conductivity, enhancing safety around electrical systems, thus delivering a compelling return on investment.

FRP industrial access steps, engineered for exceptional durability and safety in demanding environments.

Industry Trends and Strategic Adoption

The industrial access market is undergoing a significant transformation, driven by a confluence of regulatory pressures, technological advancements, and a sharpened focus on sustainability and operational efficiency. The adoption of FRP solutions, including high-performance Steps, is a central theme within these evolving trends.

- Emphasis on Lifecycle Cost (LCC): Industries are shifting from a solely upfront cost perspective to a comprehensive lifecycle cost analysis. FRP, despite potentially higher initial material costs, offers significant LCC savings due to minimal maintenance, longer lifespan, and reduced installation labor.

- Sustainability and Environmental Compliance: The demand for materials that contribute to a lower carbon footprint and are resistant to environmental degradation is growing. FRP, with its extended life and resistance to toxic chemical degradation, supports these sustainability goals.

- Advanced Manufacturing and Automation: Continuous advancements in pultrusion and composite manufacturing technologies are leading to more cost-effective, higher-quality, and more complex FRP profiles, enabling broader applications.

- Safety as a Core Value: Enhanced safety features, such as superior anti-slip properties, non-conductivity, and fire retardancy, are non-negotiable. FRP solutions intrinsically address many of these critical safety concerns.

- Customization and Modularity: The trend towards highly specific, pre-engineered solutions that can be rapidly assembled on-site reduces project timelines and minimizes operational disruptions. FRP's inherent design flexibility supports this modular approach.

The global industrial composite materials market, a key indicator for FRP adoption, is projected to grow substantially, reflecting a broad industry recognition of these materials' unparalleled benefits. Data from MarketsandMarkets indicates the global composites market size is expected to reach USD 144.3 billion by 2028, growing at a CAGR of 6.2% from 2023 to 2028 (MarketsandMarkets, 2023). This robust growth underscores the increasing strategic importance of advanced composite solutions in industrial infrastructure.

Technical Specifications and Performance Parameters

Selecting the appropriate industrial access solution requires a thorough understanding of its technical capabilities. Our FRP Steps are engineered to meet stringent performance criteria, ensuring reliable operation in the most demanding environments. The following table outlines typical specifications for our high-quality FRP stair treads, using Isophthalic Polyester resin for balanced performance in general industrial and corrosive environments.

FRP Stair Tread Specifications (Isophthalic Polyester Resin)

These detailed specifications underscore the engineered superiority of FRP solutions, providing confidence to operators and engineers regarding their structural integrity, safety compliance, and long-term performance in arduous industrial settings.

Application Scenarios and Practical Implementations

The remarkable versatility and inherent advantages of FRP Steps allow for their indispensable integration across a myriad of challenging industrial environments. Their ability to deliver consistent safety and performance where traditional materials degrade makes them the preferred choice for critical access infrastructure.

-

Coastal and Marine Environments:

In applications like offshore oil platforms, port facilities, and shipyards, constant exposure to saltwater spray, high humidity, and powerful UV radiation quickly corrodes steel and aluminum. FRP steps, utilizing specific resin systems (e.g., Vinyl Ester), offer unparalleled resistance to these elements, ensuring structural integrity and anti-slip properties for decades, significantly reducing maintenance cycles and enhancing worker safety at sea.

-

Electrical Substations and Power Generation:

Safety around high-voltage equipment is paramount. FRP's inherent non-conductive nature eliminates the risk of electrical shock, making it the material of choice for access ways, platforms, and ladder systems in power generation facilities, substations, and other electrical infrastructure. This dielectric property ensures operator safety and prevents equipment short-circuiting.

-

Data Centers and Telecommunications:

In environments sensitive to electromagnetic interference (EMI/RFI), FRP steps are ideal due to their non-magnetic properties. They do not interfere with sensitive electronic equipment, making them perfect for raised flooring access, server rack platforms, and rooftop access in telecom facilities. Their lightweight nature also simplifies installation in these often space-constrained areas.

-

Aerospace Manufacturing Facilities:

For cleanroom environments and manufacturing areas where contamination and spark hazards must be minimized, FRP offers a clean, non-corrosive, and non-sparking solution. Its dimensional stability and ability to be fabricated to high tolerances are crucial for precise assembly operations.

FRP stair treads seamlessly integrated into a complex industrial access system, offering superior chemical resistance.

Technical Advantages and Compelling ROI

The decision to implement FRP Steps is driven by a profound understanding of their intrinsic technical advantages, which collectively translate into a compelling return on investment for any industrial operation. These benefits directly impact operational efficiency, safety records, and long-term financial performance.

-

Unrivaled Corrosion and Chemical Resistance:

This is arguably the most significant advantage. FRP does not rust, pit, or corrode when exposed to acids, alkalis, salt spray, or harsh industrial chemicals. This eliminates the need for expensive coatings, galvanization, or frequent replacement, dramatically reducing maintenance costs and ensuring the structural integrity of access points over decades.

-

Exceptional Strength-to-Weight Ratio:

FRP steps are typically 70-80% lighter than equivalent steel structures, yet they offer comparable or superior load-bearing capacity. This translates to significant cost savings in transportation, reduced need for heavy lifting equipment, quicker and safer installation (often requiring fewer personnel), and decreased structural load on existing foundations.

-

Inherent Electrical and Thermal Non-Conductivity:

FRP is an excellent electrical insulator, preventing accidental electrocution in areas with live electrical equipment. It is also a poor thermal conductor, maintaining a more stable surface temperature in extreme heat or cold, enhancing worker comfort and safety. Its non-magnetic property further extends its utility in sensitive electronic environments.

-

Low Maintenance and Extended Lifecycle:

Requiring no painting, grinding, or welding throughout its operational life, FRP vastly reduces ongoing maintenance expenditures. Its resistance to UV degradation, biological growth, and impact damage ensures a service life often exceeding 25 years, maximizing the return on initial investment and minimizing operational disruptions.

These technical advantages converge to deliver a compelling ROI, making FRP solutions a strategically sound and economically prudent choice for modern industrial infrastructure.

Vendor Comparison: FRP vs. Traditional Materials

When making critical infrastructure investments, a clear comparison between material options is indispensable. While conventional materials have historically dominated, their limitations in aggressive industrial environments highlight the distinct advantages of FRP solutions. This comparison focuses on FRP steps against galvanized steel, a common traditional alternative.

FRP Steps vs. Galvanized Steel Steps: A Performance Analysis

This detailed comparison unequivocally demonstrates that while traditional materials like galvanized steel have their place, FRP steps offer a superior, more cost-effective, and safer solution for the vast majority of demanding industrial environments when considering total lifecycle cost and operational efficiency.

Customized Solutions and Design Flexibility

The strength of advanced FRP Steps lies not only in their intrinsic material properties but also in their unparalleled design flexibility and the capacity for highly customized solutions. Recognizing that every industrial site has unique challenges and architectural constraints, leading manufacturers offer bespoke engineering services to ensure optimal fit and performance.

- Resin System Selection: Tailored resin formulations (Isophthalic, Vinyl Ester, Phenolic) can be specified based on the exact chemical exposure, temperature profiles, and fire safety ratings required for a particular application, maximizing durability and compliance.

- Custom Dimensions and Profiles: Unlike standard off-the-shelf components, FRP steps can be pultruded or fabricated to precise lengths, widths, thicknesses, and complex geometries. This minimizes on-site cutting and waste, accelerating installation and reducing labor costs.

- Integrated Anti-Slip Surfaces: Various anti-slip grit levels and patterns can be integrated directly into the tread surface during manufacturing, or applied as a durable coating, to meet specific pedestrian traffic volumes and safety coefficients (e.g., in oily or wet conditions).

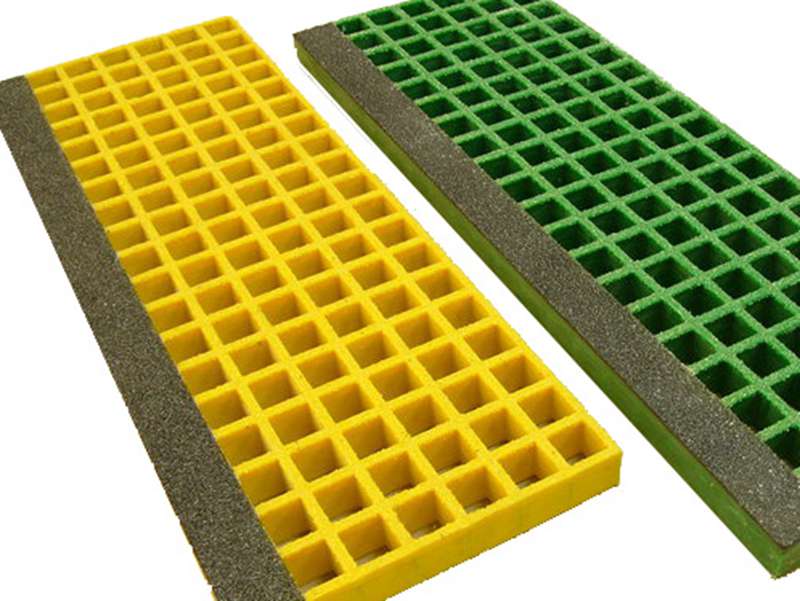

- Color and Visibility: Custom color matching can be provided for aesthetic integration or for high-visibility safety requirements. Common safety colors like yellow, grey, and green are standard options.

- Pre-fabrication and Modular Assembly: Complex stairways, platforms, and access systems can be largely pre-fabricated off-site into modular units. This significantly reduces on-site construction time, minimizing disruption to ongoing operations and enhancing safety during installation.

- Accessory Integration: Design and fabrication can include integrated toe plates, handrail posts, kickplates, and mounting brackets, ensuring a complete and cohesive access solution.

This level of customization, supported by advanced CAD/CAM capabilities and experienced engineering teams, allows for the creation of access solutions that are not only high-performing but also perfectly integrated with existing or new industrial infrastructure, maximizing safety and operational longevity.

A bespoke FRP access platform showcasing the versatility of customized solutions for complex industrial layouts.

Application Case Studies: Validated Performance in Action

Real-world deployments provide irrefutable evidence of FRP's superior performance and economic viability. These case studies highlight the successful integration of FRP solutions in challenging industrial environments, validating their benefits.

-

Case Study 1: Municipal Wastewater Treatment Plant, Europe

Challenge: A major municipal wastewater treatment plant faced recurrent failures of galvanized steel stairways and platforms due to severe corrosion from hydrogen sulfide and other aggressive chemicals prevalent in the treatment process. Maintenance costs were spiraling, and structural integrity was a constant concern.

Solution: The plant initiated a phased replacement program, installing custom-fabricated FRP stair treads, landings, and handrail systems made from Vinyl Ester resin, specifically engineered for high chemical resistance. The lightweight nature of FRP allowed for easier installation within existing concrete structures.

Result: After seven years, the FRP structures show no signs of corrosion, maintaining their vibrant color and integral anti-slip surfaces. The plant has reported a dramatic reduction in maintenance expenses (estimated at 80% compared to steel) and a significant improvement in worker safety due to consistently stable and non-degrading access points. The projected lifespan for the FRP components exceeds 25 years.

-

Case Study 2: Chemical Storage Facility, Asia

Challenge: A facility storing and handling various aggressive industrial chemicals required a new elevated access system for monitoring and maintenance of tanks. The environment presented a dual challenge: highly corrosive chemical fumes and the need for electrical isolation to prevent static discharge hazards. Traditional materials were deemed unsuitable.

Solution: A comprehensive FRP access system, including stairways, platforms, and safety cages, was designed and installed. The components were constructed using an Isophthalic Polyester resin system with enhanced chemical resistance and an integral coarse grit anti-slip surface. Its non-conductive properties were a critical safety factor.

Result: The FRP system provided immediate benefits in terms of worker safety due to its non-conductive and anti-slip characteristics. The chemical resistance has proven outstanding, with no material degradation reported since installation three years prior. The facility achieved full compliance with safety regulations and expects negligible maintenance for the foreseeable future, justifying the investment through reduced operational risk and improved safety ratings.

Trustworthiness and Comprehensive Support

Frequently Asked Questions (FAQ):

Q: How do FRP steps handle heavy foot traffic and dynamic loads?

A: Our FRP steps are engineered with high flexural and compressive strengths to withstand significant loads and continuous foot traffic. They are designed in accordance with relevant loading standards (e.g., OSHA, IBC) and tested to ensure long-term structural integrity in demanding industrial environments.

Q: Is FRP difficult to cut or modify on-site?

A: FRP can be easily cut, drilled, and fabricated using standard carpenter's tools with appropriate dust extraction. This flexibility allows for minor adjustments on-site, though pre-fabrication to exact specifications is always recommended to maximize efficiency and minimize waste.

Q: What are the fire safety ratings for FRP steps?

A: We offer FRP steps with various fire retardancy ratings, including ASTM E-84 Class 1 (Flame Spread Index ≤ 25), achieved through the use of specific resin systems like Phenolic or fire-retardant Isophthalic resins. This ensures compliance with stringent fire safety codes in industrial facilities.

Lead Time and Fulfillment Details:

For standard FRP profiles, typical lead times range from 2 to 4 weeks from confirmed order, subject to current production schedules and material availability. Custom-engineered solutions and large-volume projects will have specific lead times determined during the detailed project planning phase. We prioritize efficient supply chain management and transparent communication to ensure timely delivery and seamless project execution for our clients globally.

Warranty Commitments:

Our commitment to quality is unwavering. All our FRP steps and related access solutions are backed by a comprehensive 10-year limited warranty against manufacturing defects and material failures under normal operating conditions. This warranty reflects our confidence in the durability and longevity of our products. Detailed warranty terms and conditions are available upon request and are provided with all quotations.

Customer Support and After-Sales Service:

We believe that exceptional customer support is integral to project success. Our dedicated team of technical experts and engineers provides comprehensive support from initial consultation and design assistance to installation guidance and ongoing after-sales service. We are committed to ensuring that our clients achieve optimal performance and maximum value from their FRP investments throughout the entire product lifecycle.

Conclusion

The adoption of FRP Steps signifies a crucial strategic evolution in industrial infrastructure management. Offering a compelling combination of superior corrosion and chemical resistance, high strength-to-weight ratios, intrinsic safety (non-conductive, anti-slip), and significantly reduced lifecycle costs, these advanced composite solutions fundamentally outperform traditional materials in challenging environments. By investing in precision-engineered FRP access systems, B2B decision-makers and engineers can ensure long-term operational integrity, enhance worker safety, minimize maintenance burdens, and achieve substantial economic advantages. This commitment to modern material science is not merely an upgrade; it is an investment in the resilience, efficiency, and future-proof nature of industrial operations.

References:

- MarketsandMarkets. (2023). Composites Market by Fiber Type, Resin Type, Manufacturing Process, End-use Industry, and Region – Global Forecast to 2028. www.marketsandmarkets.com/Market-Reports/composite-market-200051283.html

- ASTM International. (n.d.). Latest Standards for Plastics, Composites, and Adhesives. www.astm.org/products-services/standards-and-publications/standards/plastics.html

- International Organization for Standardization (ISO). (n.d.). ISO 9001: Quality management systems. www.iso.org/iso-9001-quality-management.html

- American National Standards Institute (ANSI). (n.d.). Safety Standards & Conformity Assessment. www.ansi.org/standards-certifications/safety-health

- OSHA. (n.d.). Safety and Health Regulations for Construction. www.osha.gov/laws-regs/regulations/standardnumber/1926

Latest news

-

Practical Steps: Unlock Success with Our Proven GuidesNewsAug.24,2025

-

Transport Tanks: Safe, Durable & Efficient Liquid HaulingNewsAug.23,2025

-

High-Quality Piping Systems for Efficient Flow & DurabilityNewsAug.22,2025

-

High-Efficiency Insulation Tanks for Optimal Temperature ControlNewsAug.11,2025

-

Premium Oblate Tanks: Space-Saving & Efficient Liquid StorageNewsAug.10,2025

-

High-Performance Insulation Tanks for Optimal Energy SavingsNewsAug.09,2025