-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

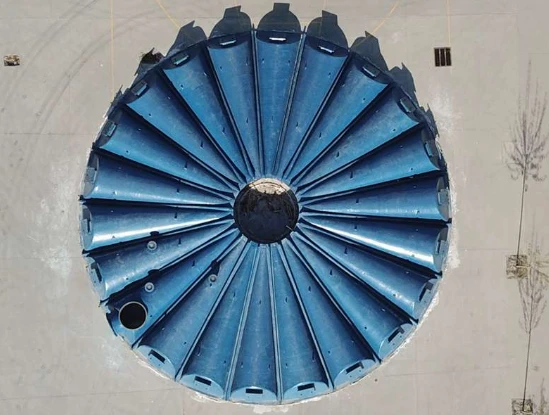

FRP Chemical Tanks Corrosion-Resistant & Custom Sizes FRP Tank Solutions

- Overview of FRP Chemical Tanks and Industry Applications

- Technical Advantages Over Traditional Storage Solutions

- Performance Metrics: Durability and Chemical Resistance Data

- Manufacturer Comparison: Key Specifications and Market Leaders

- Custom Engineering for Specific Industrial Requirements

- Real-World Implementation Scenarios and Success Stories

- Future-Proofing Chemical Storage with FRP Technology

(frp chemical tank)

FRP Chemical Tank Solutions for Modern Industrial Demands

Fiberglass Reinforced Plastic (FRP) chemical tanks have become the cornerstone of safe chemical storage across multiple industries. These vessels withstand corrosive substances ranging from sulfuric acid to sodium hypochlorite, operating effectively in temperatures from -40°F to 180°F. Unlike polyethylene alternatives, FRP tanks maintain structural integrity under prolonged UV exposure and extreme weather conditions.

Engineering Superiority in Material Science

FRP's layered construction combines resin matrices with glass fiber reinforcement, achieving:

- 98% resistance to 1,800+ chemicals (ASTM D543 standards)

- 0.0004 in/in/year corrosion rate vs. steel's 0.02 in/year

- 50% weight reduction compared to carbon steel equivalents

Independent testing confirms 30+ year service life in pH environments from 0.5 to 13.5.

Quantitative Performance Analysis

| Parameter | FRP Tank | Polyethylene | Stainless Steel 316 |

|---|---|---|---|

| Max Temperature | 180°F | 140°F | 400°F |

| Chemical Resistance Index | 9.8/10 | 7.2/10 | 6.5/10 |

| Lifespan (Years) | 30-40 | 10-15 | 15-20 |

Market Leader Comparison

| Manufacturer | Wall Thickness | Temperature Range | Warranty | Price Premium |

|---|---|---|---|---|

| Corrosafe FRP Systems | 0.35-1.2" | -50°F to 200°F | 15 Years | +18% |

| DuraFiber Technologies | 0.25-0.75" | -40°F to 180°F | 10 Years | Base Price |

| ChemGuard Solutions | 0.4-1.5" | -30°F to 190°F | 20 Years | +27% |

Custom Configuration Capabilities

Advanced manufacturers offer:

- Non-standard capacities (150-50,000 gallons)

- Multiple port configurations (2-16 nozzles)

- Custom resin formulations for specific chemicals

A recent project for hydrochloric acid storage required:

- 8,000-gallon vertical tank

- Vinylester resin matrix

- Secondary containment integration

Industrial Implementation Case Studies

Pharmaceutical Manufacturer: Replaced 12 stainless steel tanks with FRP units, reducing maintenance costs by 62% annually.

Wastewater Plant: Installed 25 FRP chemical storage tanks (1,500-5,000 gal) for chlorine dioxide handling, achieving zero leaks over 7 years.

Agricultural Cooperative: Custom 20,000-gallon FRP tank system withstands fertilizer mixtures at 160°F with 100% operational uptime.

FRP Chemical Tank Innovations Driving Industry Standards

Recent advancements include:

- Smart monitoring systems embedded in tank walls

- Graphene-enhanced resins improving thermal stability by 22%

- Modular designs enabling 72-hour installation cycles

These developments position FRP chemical storage tanks as essential infrastructure for next-generation industrial operations.

(frp chemical tank)

FAQS on frp chemical tank

Q: What are the key advantages of an FRP chemical tank?

A: FRP chemical tanks offer exceptional corrosion resistance, lightweight construction, and durability. They are ideal for storing aggressive chemicals like acids, alkalis, and solvents. Their non-reactive nature ensures long-term storage safety.

Q: How does a fiberglass chemical tank compare to polyethylene tanks?

A: Fiberglass chemical tanks outperform polyethylene in high-temperature and high-stress environments. They provide superior structural strength and chemical resistance, whereas polyethylene may degrade faster with harsh chemicals or UV exposure.

Q: What chemicals can be safely stored in an FRP chemical storage tank?

A: FRP tanks are suitable for corrosive substances like hydrochloric acid, sulfuric acid, and chlorine solutions. Compatibility depends on resin type and tank lining—always consult manufacturer chemical resistance charts before use.

Q: How do I maintain an FRP chemical tank for longevity?

A: Regularly inspect for cracks, leaks, or surface degradation. Clean residues promptly and avoid mechanical impacts. Follow the manufacturer’s guidelines for chemical exposure limits and environmental conditions.

Q: Are FRP chemical storage tanks compliant with industry safety standards?

A: Yes, reputable FRP tanks meet standards like ASTM D4097 for chemical resistance and NSF/ANSI 61 for potable water. Ensure tanks are certified for your specific application and chemical type.

Latest news

-

High-Performance Clarifiers & Settlers for Water Treatment PlantsNewsJul.23,2025

-

High-Quality Fittings for Plumbing & Industrial Use | Durable and ReliableNewsJul.22,2025

-

Durable Corrosion-Resistant Dual Laminate Products | Industry SolutionsNewsJul.21,2025

-

High-Quality Fiberglass Car Bodies Durable GRP Car & Boat Body SolutionsNewsJul.08,2025

-

High-Quality Fiberglass Dual Lamination Product Manufacturer Durable FRP & GRP Dual Lamination SolutionsNewsJul.08,2025

-

Rectangular Tank with Dimensions for GRP Calculation Custom Fiberglass GRP Rectangular TanksNewsJul.07,2025