-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring the Efficiency and Benefits of Air-Operated Rock Drilling Technologies for Construction Projects

The Power of Air An Insight into Air Powered Rock Drills

Air powered rock drills have become an essential tool in various industries, particularly in mining, construction, and quarrying. These powerful devices harness the energy of compressed air to penetrate hard rock, making them invaluable for tasks such as excavation, tunneling, and rock blasting. Understanding the functionality, benefits, and applications of air powered rock drills can illuminate their pivotal role in modern construction and mining operations.

At the heart of an air powered rock drill is its unique mechanism that converts compressed air into kinetic energy. This process begins with a compressor generating pressurized air, which is then directed into the drill. The air pressure forces a piston or a hammer within the drill to move rapidly back and forth. This motion is then translated into impact energy, which is transferred to the drill bit that strikes the rock surface. The design of the drill allows for high penetration rates while maintaining the ability to operate effectively in harsh environments.

One significant advantage of air powered rock drills is their lightweight and portable design. Unlike electric drills, which can be cumbersome and require a constant power supply, air drills can be easily transported and used in remote locations where electricity may not be readily available. This mobility is especially beneficial in mining and construction sites, often located in challenging terrains. Moreover, the use of compressed air diminishes the risk of electric shock, making these tools safe for operators working in wet or hazardous conditions.

Another noteworthy benefit of air powered rock drills is their efficiency and speed. These drills typically achieve higher penetration rates than electric counterparts, enabling faster completion of drilling tasks. This efficiency translates into cost savings for construction companies and mining operations, as they can complete projects within tighter timelines. Additionally, reduced downtime due to tool malfunctions is an economic advantage; air drills are generally more resilient to heavy usage.

air powered rock drill

Air powered rock drills also produce less heat during operation compared to electric drills, which can lead to longer tool life and reduced maintenance costs. The absence of electric components minimizes the risk of overheating and burnout, while the simplicity of the design allows for easier repairs and replacements. Operators can maintain these drills with basic tools, further enhancing their longevity.

The applications of air powered rock drills are vast and varied. In mining, they are used to create blast holes for explosives, allowing for the systematic extraction of minerals. In construction, they facilitate the creation of foundations, tunnels, and roads by efficiently breaking through solid rock. Additionally, they have found applications in the demolition industry, where breaking down concrete structures is required.

However, while air powered rock drills offer numerous advantages, it is important for operators to be aware of best practices and safety measures. Proper training is essential to ensure that personnel can handle these powerful tools effectively. Using appropriate personal protective equipment (PPE), including hearing protection and safety goggles, is critical as air drills can produce significant noise levels and flying debris.

In conclusion, air powered rock drills exemplify the synergy between technology and practicality in heavy industries. Their ability to harness air pressure for efficient and effective rock drilling speaks to their importance in construction and mining. As the industries continue to evolve, the role of these powerful tools is likely to expand, reinforcing their status as indispensable to modern engineering and excavation tasks. With ongoing advancements in technology, we can expect air powered rock drills to become even more efficient and user-friendly, further solidifying their place in the toolkits of professionals across the globe.

Latest news

-

Fiberglass 90 Degree Elbow for Custom Tanks & High Pressure Pipes Durable and Corrosion ResistantNewsJun.24,2025

-

Exploring the Benefits of Top Hammer Drifter Rods for Enhanced Drilling PerformanceNewsJun.10,2025

-

High-Precision Fiberglass Winding Machine for GRP/FRP Pipe Production – Reliable & Efficient SolutionsNewsJun.10,2025

-

FRP Pipes & Fittings for Shipbuilding - Corrosion-Resistant & LightweightNewsJun.09,2025

-

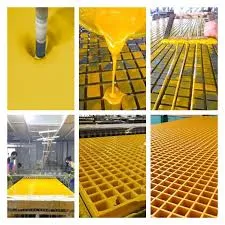

Premium FRP Flooring Solutions Durable & Slip-ResistantNewsJun.09,2025

-

Premium Fiberglass Rectangular Tanks Durable & Lightweight SolutionNewsJun.09,2025