-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

China (Taiwan)

China (Taiwan) -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

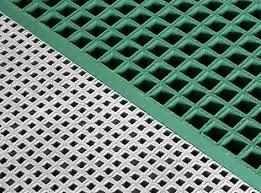

Food Grade Fiberglass Equipment for Safe and Durable Food Handling Solutions

The Importance of Fiberglass Food Grade Equipment in the Food Industry

In the rapidly evolving food industry, the safety and quality of food production are paramount. As businesses strive to meet stringent health standards, the materials used in food processing and handling are undergoing significant scrutiny. Among these materials, fiberglass has emerged as a vital component in food grade equipment, offering a range of benefits that can enhance both safety and efficiency in food operations.

Fiberglass, a composite material made from fine fibers of glass, is increasingly being employed in various food-grade applications due to its excellent durability, resistance to corrosion, and non-reactive properties. This makes fiberglass an ideal choice for equipment that will come into direct contact with food products. Unlike metals, which can corrode or react with food substances, fiberglass remains inert, ensuring that there is no contamination or alteration of food quality. This characteristic is crucial in maintaining the integrity of food products and adhering to stringent FDA regulations regarding food safety.

One of the most notable advantages of fiberglass food grade equipment is its lightweight nature. Unlike traditional metal components, fiberglass is significantly lighter, making it easier to handle and install. This can lead to reductions in shipping costs and labor expenses during maintenance and cleaning procedures. The lightweight quality of fiberglass also means that food processing facilities can be designed with flexibility in mind, allowing for easier modifications and upgrades in production lines without the need for heavy-duty structural changes.

Additionally, fiberglass is remarkably robust and can withstand harsh environments, including extreme temperatures and chemical exposure. In food processing, where cleaning agents and high-temperature conditions are common, fiberglass equipment can maintain its structural integrity without degrading over time. This durability translates into lower long-term maintenance costs, as there is less need for replacement or extensive repairs.

fiberglass food grade equipment

Another vital aspect of fiberglass food grade equipment is its ease of cleaning and sanitation. The smooth surfaces of fiberglass are resistant to bacterial growth and do not harbor contaminants, making them ideal for applications in the food industry where hygiene is critical. Cleaning processes are streamlined, reducing labor costs, and ensuring compliance with health department standards.

Moreover, the versatility of fiberglass allows for the creation of customized equipment tailored to specific operational requirements. Whether for storage tanks, conveyor systems, or processing tables, fiberglass can be molded into various shapes and sizes to suit the unique needs of food manufacturing facilities. This customization not only enhances efficiency but also optimizes space, allowing manufacturers to maximize their operational capacity.

In recent years, the increasing consumer demand for sustainability has led many food businesses to seek eco-friendly materials. Fiberglass is a sustainable option as it can be produced using recycled glass, reducing environmental impact while still meeting food safety standards. By choosing fiberglass, companies can demonstrate their commitment to environmental stewardship, which is becoming an essential aspect of modern food production.

In conclusion, fiberglass food grade equipment plays a crucial role in the food industry, providing a combination of safety, durability, and versatility. Its non-reactive properties, ease of cleaning, and customization options make it an attractive choice for food manufacturers aiming to enhance their operational efficiency while maintaining high safety standards. As the industry continues to evolve and prioritize food safety and sustainability, fiberglass is positioned to remain an invaluable asset in the production of safe, high-quality food products.

Latest news

-

Oblate Tanks: Space-Saving, Durable Liquid Storage SolutionsNewsAug.27,2025

-

High-Performance Piping System Solutions for Industry & Commercial UseNewsAug.26,2025

-

Precision Fittings: Durable & Reliable Industrial & Plumbing SolutionsNewsAug.25,2025

-

Practical Steps: Unlock Success with Our Proven GuidesNewsAug.24,2025

-

Transport Tanks: Safe, Durable & Efficient Liquid HaulingNewsAug.23,2025

-

High-Quality Piping Systems for Efficient Flow & DurabilityNewsAug.22,2025